Single-trolley and double-beam ladle crane with non-translating cast secondary hook

A technology of crane and trolley, which is applied in the field of single trolley double girder casting crane, can solve the problems affecting the quality of finished steel and castings, increase the instability of molten steel casting, and the impact of ladle, so as to achieve easy intelligent unmanned control and stable pouring strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to have a clearer understanding of the technical content of the present invention, specific implementations are specifically described in detail.

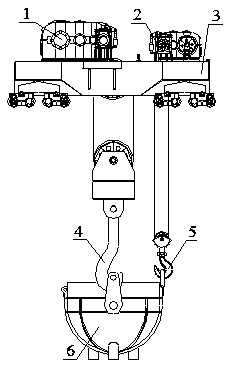

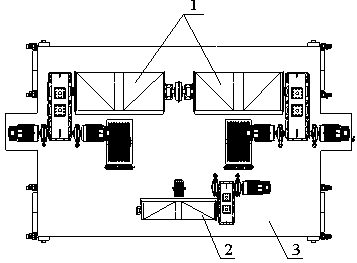

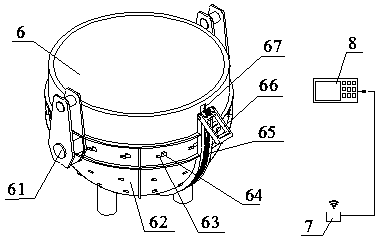

[0018] The single-trolley double-girder casting crane with a single-cart and double-girder casting crane with a main hook lifts the hemispherical ladle to the position where molten steel needs to be poured. When the auxiliary hook is not hooked, the auxiliary hook hanger is tilted outside the chain or wire rope groove. In the groove on the top of the stretch rib, it is convenient for the auxiliary hook to hook. When the ladle needs to be tipped over, the main hook is hung on the main hook hanging point and remains still, and the auxiliary hook is gradually lifted after being hung on the auxiliary hook spreader, and the chain or wire rope is used to drive the ladle to rotate to complete the dumping of molten steel or cleaning of steel slag. Since the ladle rotates around the trunnion, and the hemispherical pot-shaped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com