High-performance pearlized film and preparation method thereof

A pearlescent film and high-performance technology, applied in the field of high-performance pearlescent film and its preparation, can solve the problems of decreased film strength and increased cost, and achieve the effects of reducing strength, increasing strength, and improving pearlescent effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

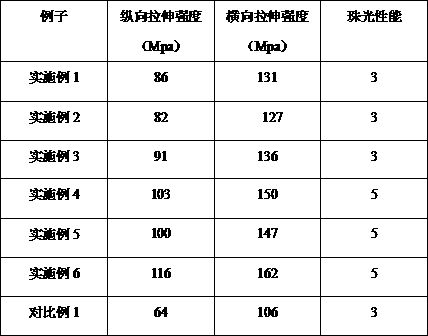

Examples

Embodiment 1

[0038] (1) 100 parts by weight of polypropylene resin with a weight average molecular weight of 200,000, 0.1 parts by weight of zinc stearate, 0.1 parts by weight of white oil, 0.1 parts by weight of antioxidant 1010 and 20 parts by weight of the average particle diameter The superfine calcium carbonate of 20 nanometers is dried in a drier, the temperature of the drier is 110°C, and the drying time is 8 hours;

[0039] (2) Put the dried material into the mixer, stir and mix at a temperature of 80°C to form a plasticized material;

[0040] (3) Feed the stirred plastic material to the extrusion feeder, and then extrude it in the form of melt and send it to the quenching roller to cool it into a cast sheet. The temperature of the extruder is 220°C, and the melt The melting temperature is 270°C;

[0041] (4) Stretch and cool the cast sheet through a two-way stretching machine. The longitudinal stretching ratio is 3 times. The stretch ratio is 3 times, the transverse stretching p...

Embodiment 2

[0046] (1) 100 parts by weight of polypropylene resin with a weight average molecular weight of 700000, 5 parts by weight of zinc stearate, 2 parts by weight of white oil, 5 parts by weight of antioxidant 1010 and 50 parts by weight of the average particle diameter The superfine calcium carbonate of 200 nanometers is dried in a drier, the temperature of the drier is 110°C, and the drying time is 8 hours;

[0047] (2) Put the dried material into the mixer, stir and mix at a temperature of 80°C to form a plasticized material;

[0048] (3) Feed the stirred plastic material to the extrusion feeder, and then extrude it in the form of melt and send it to the quenching roller to cool it into a cast sheet. The temperature of the extruder is 220°C, and the melt The melting temperature is 270°C;

[0049](4) Stretch and cool the cast sheet through a two-way stretching machine. The longitudinal stretching ratio is 3 times. The stretch ratio is 3 times, the transverse stretching preheati...

Embodiment 3

[0054] (1) 100 parts by weight of polypropylene resin with a weight average molecular weight of 650000, 1 part by weight of zinc stearate, 0.5 parts by weight of white oil, 2 parts by weight of antioxidant 1010 and 46 parts by weight of the average particle diameter The superfine calcium carbonate of 120 nanometers is dried in a drier, the temperature of the drier is 110°C, and the drying time is 8 hours;

[0055] (2) Put the dried material into the mixer, stir and mix at a temperature of 80°C to form a plasticized material;

[0056] (3) Feed the stirred plastic material to the extrusion feeder, and then extrude it in the form of melt and send it to the quenching roller to cool it into a cast sheet. The temperature of the extruder is 220°C, and the melt The melting temperature is 270°C;

[0057] (4) Stretch and cool the cast sheet through a two-way stretching machine. The longitudinal stretching ratio is 3 times. The stretch ratio is 3 times, the transverse stretching prehea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com