Turbocharger with electronic fast start split structure

A turbocharger, quick-start technology, applied in engine components, combustion engines, machines/engines, etc., can solve problems such as air-fuel ratio, achieve the effect of reasonable and ingenious structure, and solve the problem of air-fuel ratio boosting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

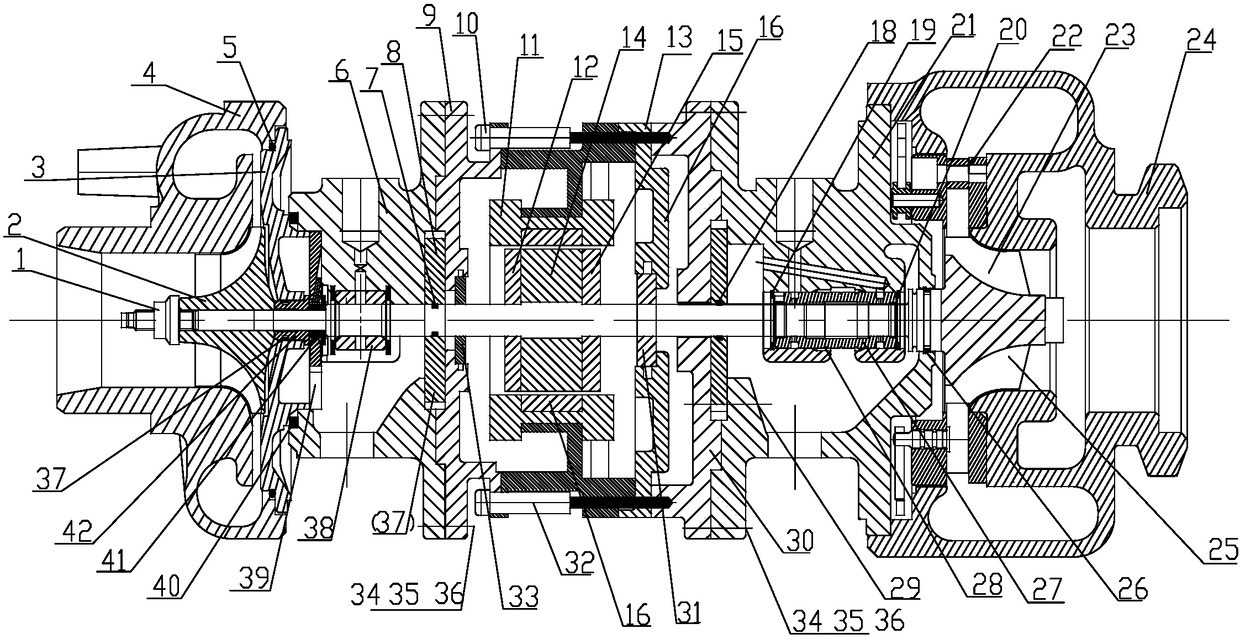

[0016] figure 1 , including lock nut 1, compressor impeller 2, diffuser 3, compressor casing 4, first rubber sealing ring 5, first intermediate casing 6, first sealing ring 7, first sealing ring seat 8, left end Cover 9, first connecting screw 10, motor casing 11, first photoelectric switch 12, motor cover plate 13, rotor 14, second photoelectric switch 15, stator core 16, second sealing ring seat 17, second sealing ring 18 , the first circlip 19, the second circlip 20, the second intermediate shell 21, the VTG (variable geometry turbine blade) assembly 22, the turbine main shaft 23, the turbine shell 24, the turbine 25, the turbine end seal ring 26, the first Second bearing 27, first positioning pin 28, second positioning pin 29, right end cover 30, first sealing member 31, second connecting screw 32, second sealing member 33, nut 34, posi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap