Particle dryer

A particle drying and cabinet technology, which is applied to the drying of granular materials, non-progressive dryers, dryers, etc., can solve the problems of poor drying effect of material particles, achieve enhanced drying effect, good drying effect, and improve efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

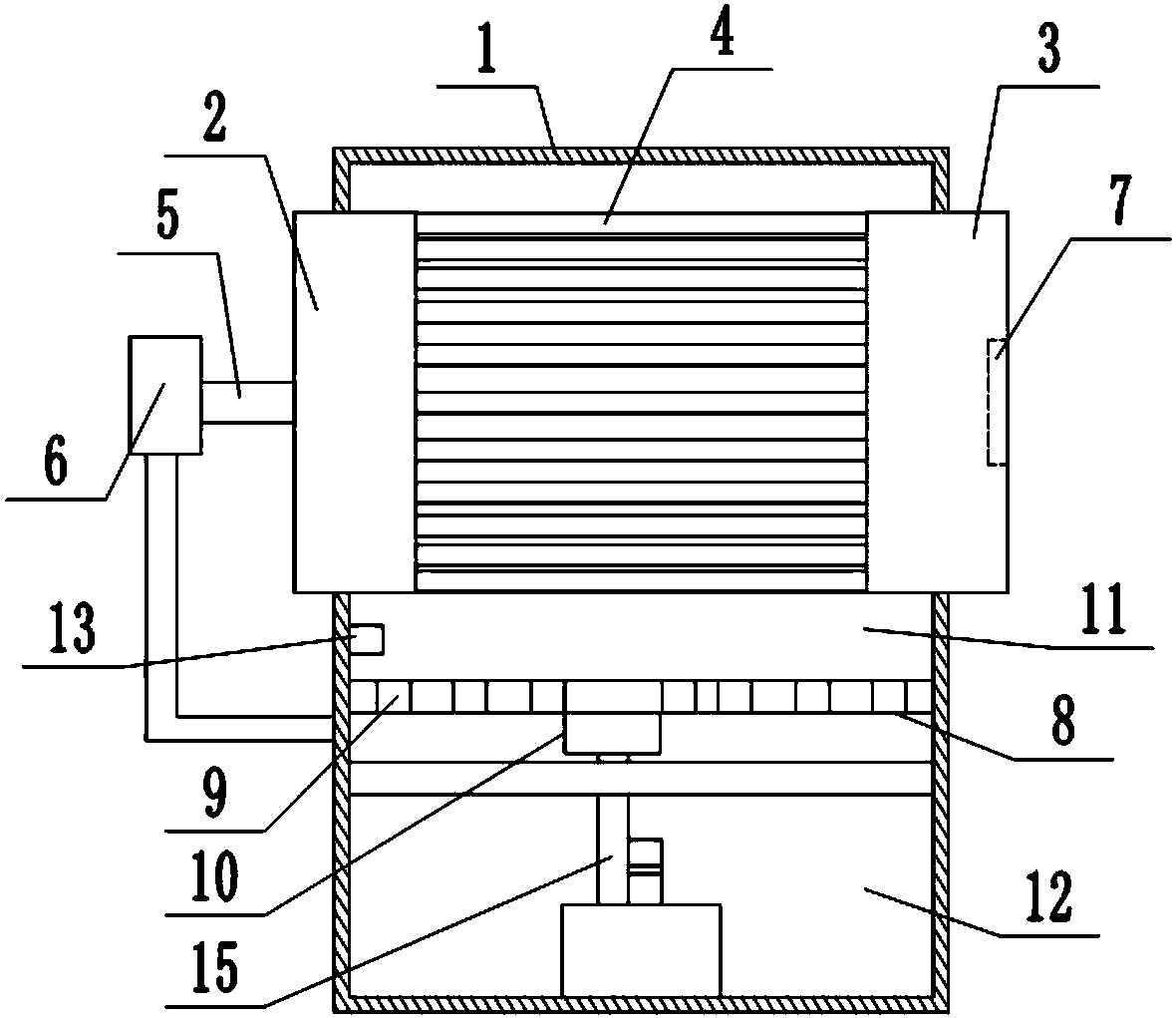

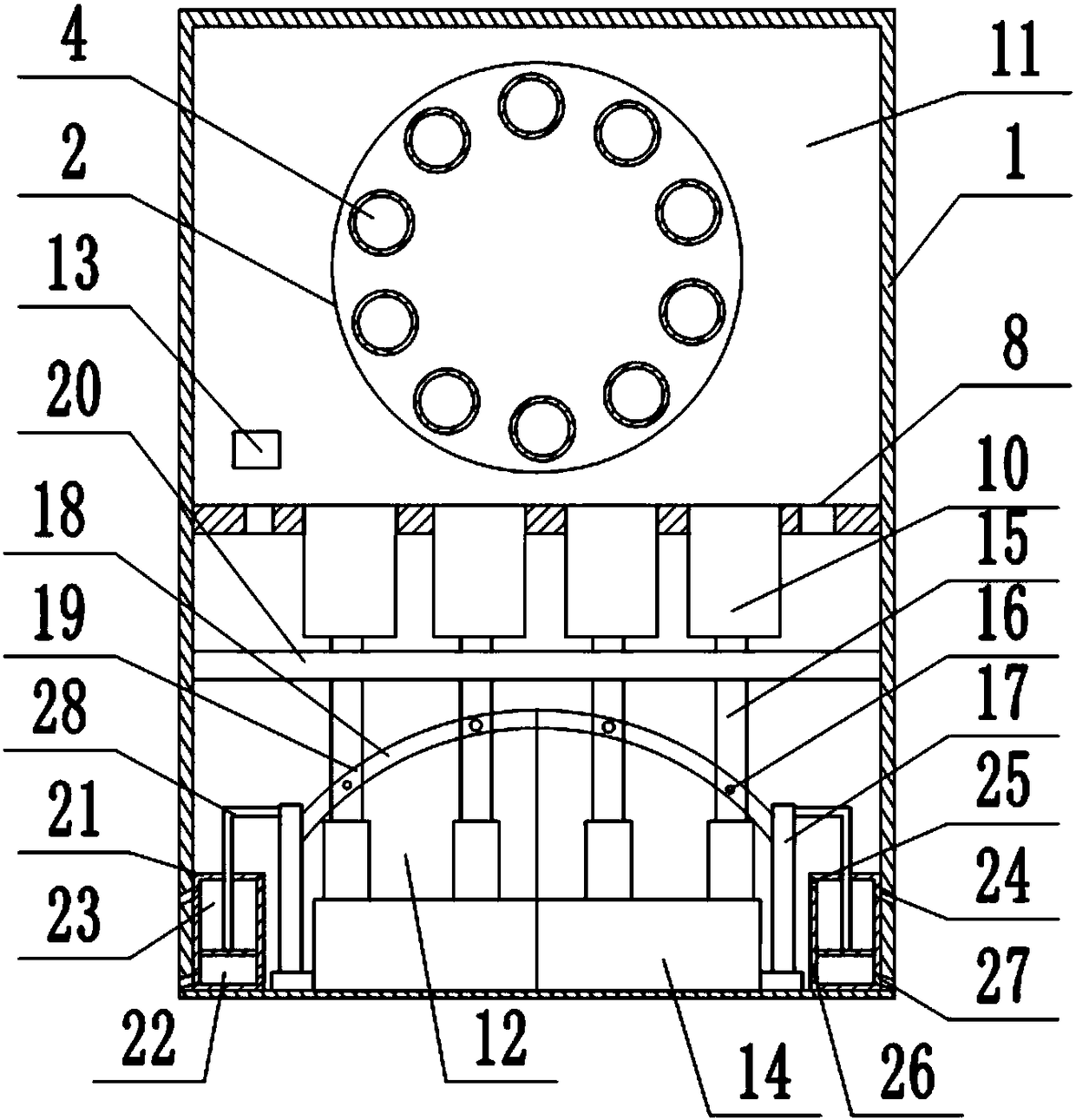

[0022] The following is further described in detail through specific implementation methods:

[0023] The reference signs in the drawings of the description include: box 1, turntable 2, second turntable 3, feeding pipe 4, rotating shaft 5, motor 6, negative pressure fan 7, partition plate 8, air inlet 9, connecting pipe 10, Combustion chamber 11, movable chamber 12, igniter 13, fuel supply tank 14, plunger 15, connecting column 16, cylinder 17, elastic sheet 18, chute 19, baffle plate 20, cylinder body 21, suction part 22, air supply Part 23, first air inlet 24, first air outlet 25, second air inlet 26, second air outlet 27, connecting rod 28.

[0024] The embodiment is basically as attached figure 1 And attached figure 2 Shown:

[0025] The particle dryer is mainly composed of a box body 1, a feeding mechanism, an elastic sheet 18, a fuel pipe, a connecting pipe 10, a cylinder 17, a cylinder body 21, and a plunger 15. The outside of the box body 1 is provided with a heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com