A method for detecting surface defects of magnetic circuit materials

A defect and magnetic circuit technology, which is applied in the field of detection of surface defects of magnetic circuit materials based on deep learning algorithms, can solve the problems of random shape of surface defects, waste of time, low contrast, etc., to improve the recognition rate of defects and improve the quality of the factory Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] As mentioned above, in view of the deficiencies in the prior art, the inventor of this case was able to propose the technical solution of the present invention after long-term research and extensive practice. The technical solutions of the present invention will be clearly and completely described below, and obviously, the described embodiments are part of the embodiments of the present invention, not all of them. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

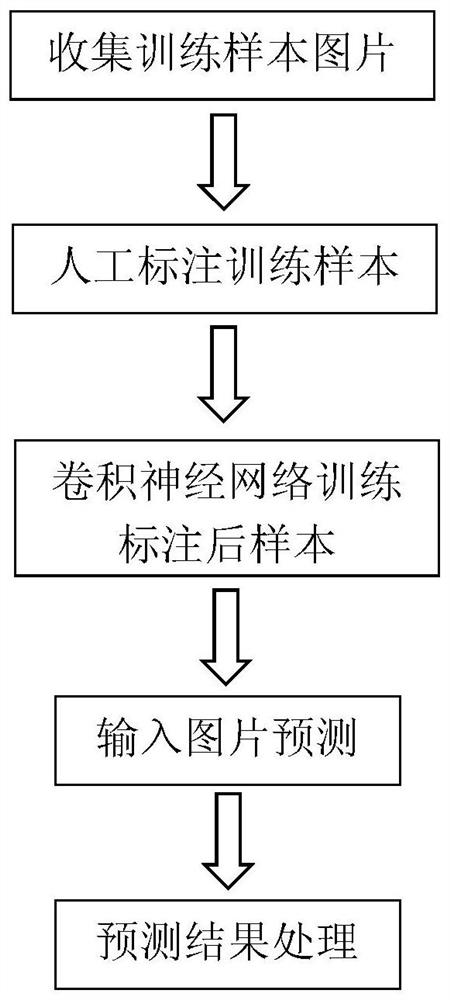

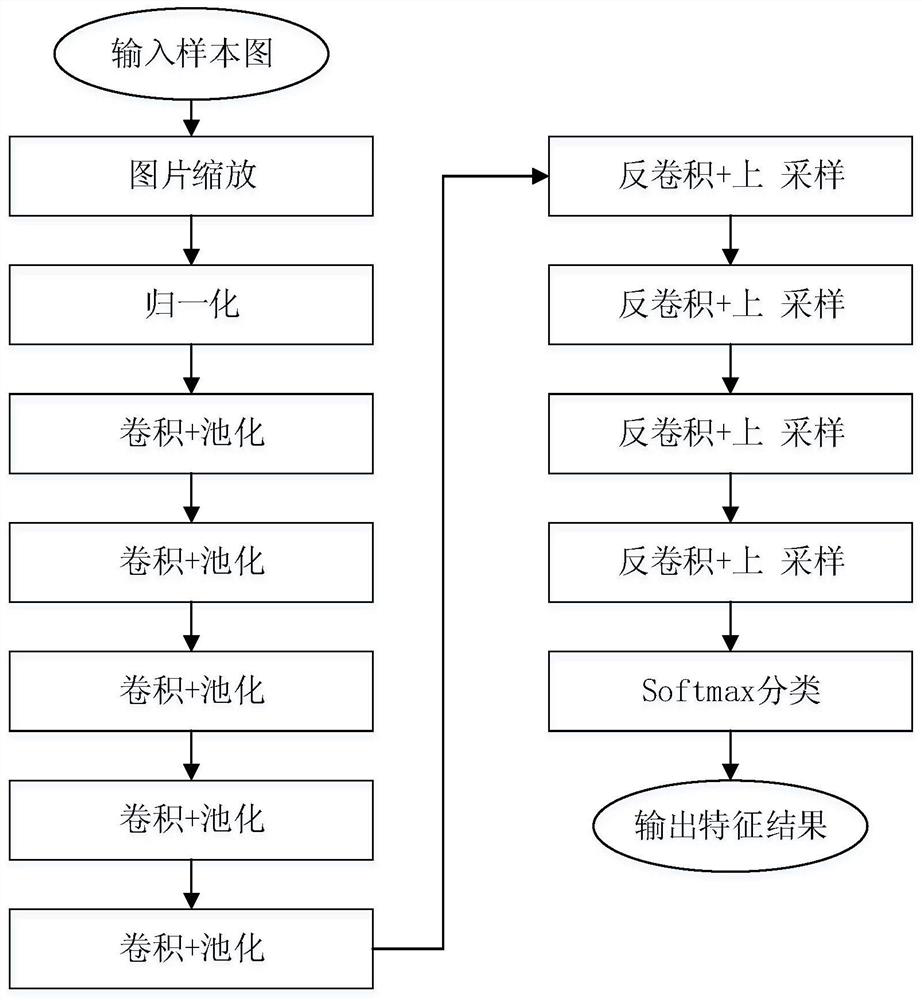

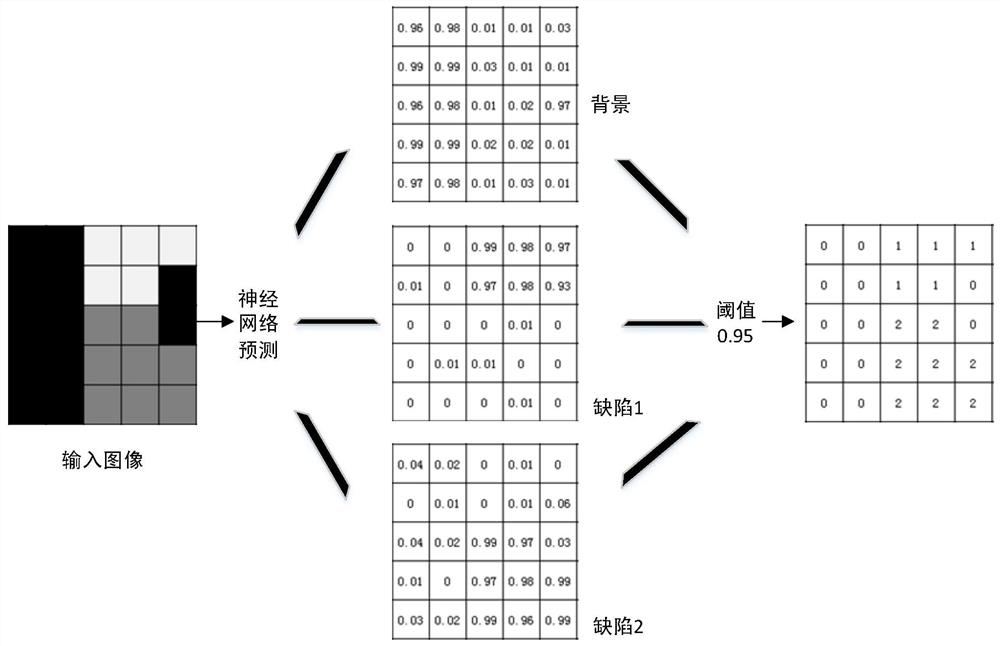

[0029] As mentioned above, after long-term research and practice, the inventor of this case proposed a new type of surface defect detection method for magnetic circuit materials, which mainly uses a classification algorithm based on a deep convolutional neural network, in which the input image block is compressed and Cutting and importing a classifier...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com