Method for processing Nd: YAG laser crystal through Brewster angle

A Brewster angle, laser crystal technology, applied in lasers, laser parts, structures/shapes of active media, etc., can solve the problems of laser damage to the coating layer, reduced surface finish, and high overall cost of optical components, reducing the Processing cost, avoiding the effect of crystal coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

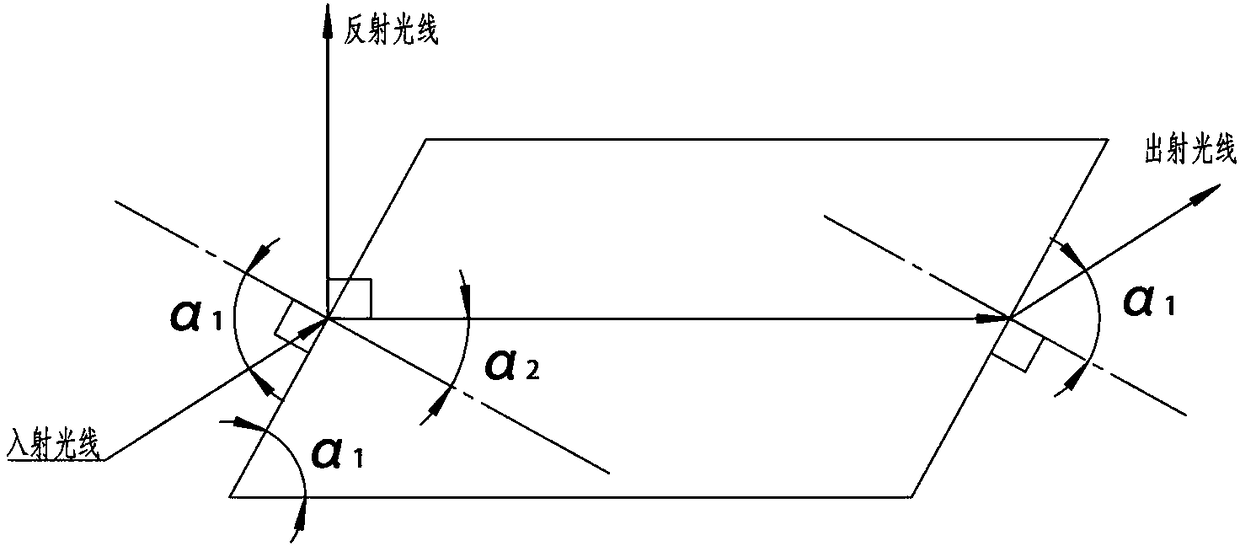

[0018] The present invention proposes a kind of method that adopts Brewster angle processing Nd:YAG laser crystal, carries out according to following steps:

[0019] Step 1, material selection of crystal

[0020] The selection of materials adopts He-Ne laser irradiation to irradiate visible scattering points with the naked eye;

[0021] Step 2. Orientation of the crystal

[0022] The orientation adopts an X-ray orientation instrument; the crystal cutting adopts an X-ray orientation instrument;

[0023] Step 3. Crystal cutting

[0024] For the crystal cutting, an X-ray orientation instrument is used to process the two end faces of the laser crystal into Brewster’s angles, and the parallelism is ensured; the Brewster’s angle of the crystal cutting, the incident light is at the incident interface When it is incident at Brewster's angle, the refracted light can propagate along the direction parallel to the side of the optical element, and enter the air medium through the revers...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com