Novel cable pre-embedding equipment for power construction

A technology for electric power construction and cables, which is applied in the direction of cable laying equipment, mechanical equipment, electrical components, etc., can solve the problems of slow work efficiency and large manpower consumption, and achieve the effect of convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

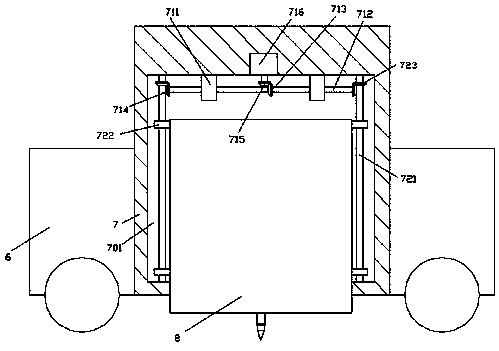

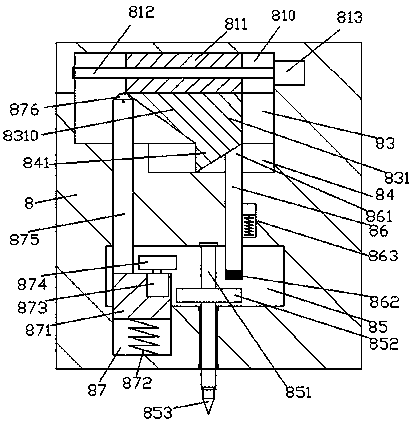

[0014] like Figure 1-Figure 3 As shown, a new type of cable pre-embedding equipment for electric power construction of the present invention includes a moving frame 6 and a fixing base 7 fixedly installed in the moving frame 6. The fixing base 7 A accommodating cavity 701 is provided, and the excavation frame 8 is installed in the accommodating cavity 701 by sliding up and down through the lifting and lowering execution member. The seat 711 and the rotating studs 721 mounted on the left and right ends of the mounting seat 711 in a rotating fit. A first tapered wheel 713 is fixedly installed to the left and right and a second tapered wheel 714 is fixedly installed at the end of the left and right extension. The first tapered wheel 713 is matched with a third tapered wheel 715. The top end surface is fixedly installed with the power output shaft of the first driving machine 716 , the outer surface of the first driving machine 716 is installed in the mounting base 7 and is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com