Efficient dust removal equipment for textile workshops

A dust removal equipment and high-efficiency technology, applied in cleaning equipment, applications, vacuum cleaners, etc., can solve the problems of low dust removal efficiency, limited service life, easy to be affected by the workshop environment, etc., to improve dust removal efficiency, increase pressure life, and improve suction. Dust effect and service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

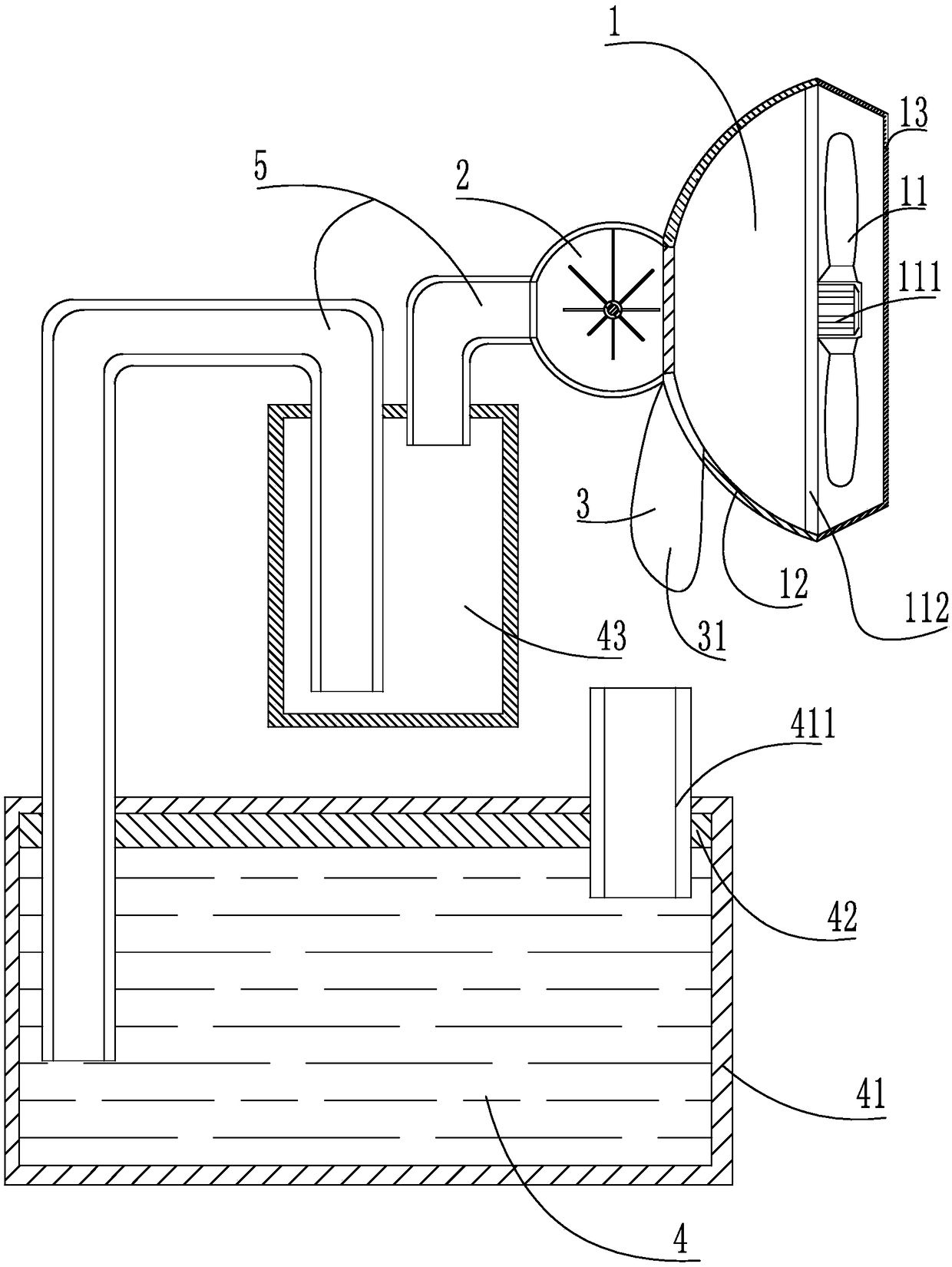

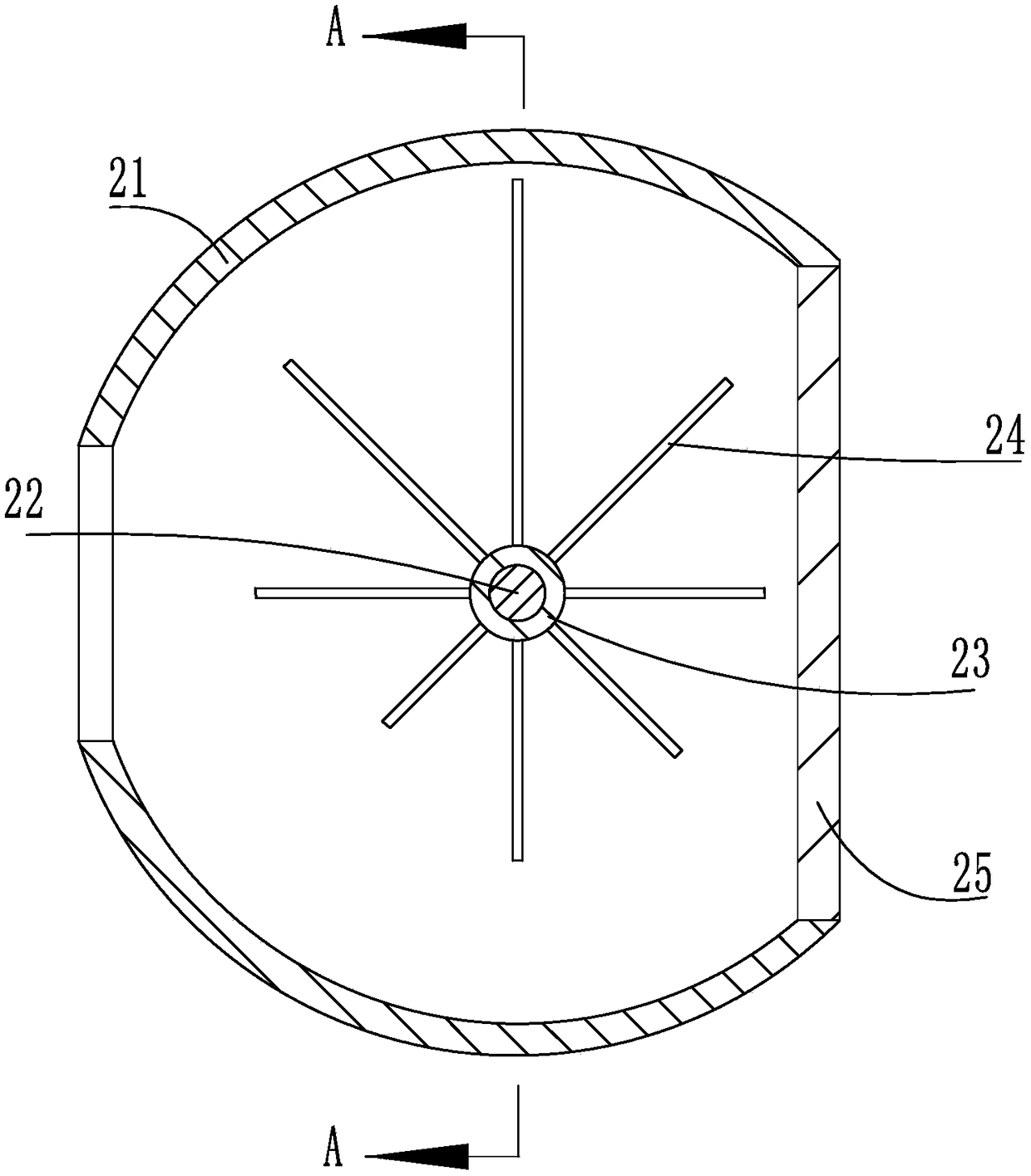

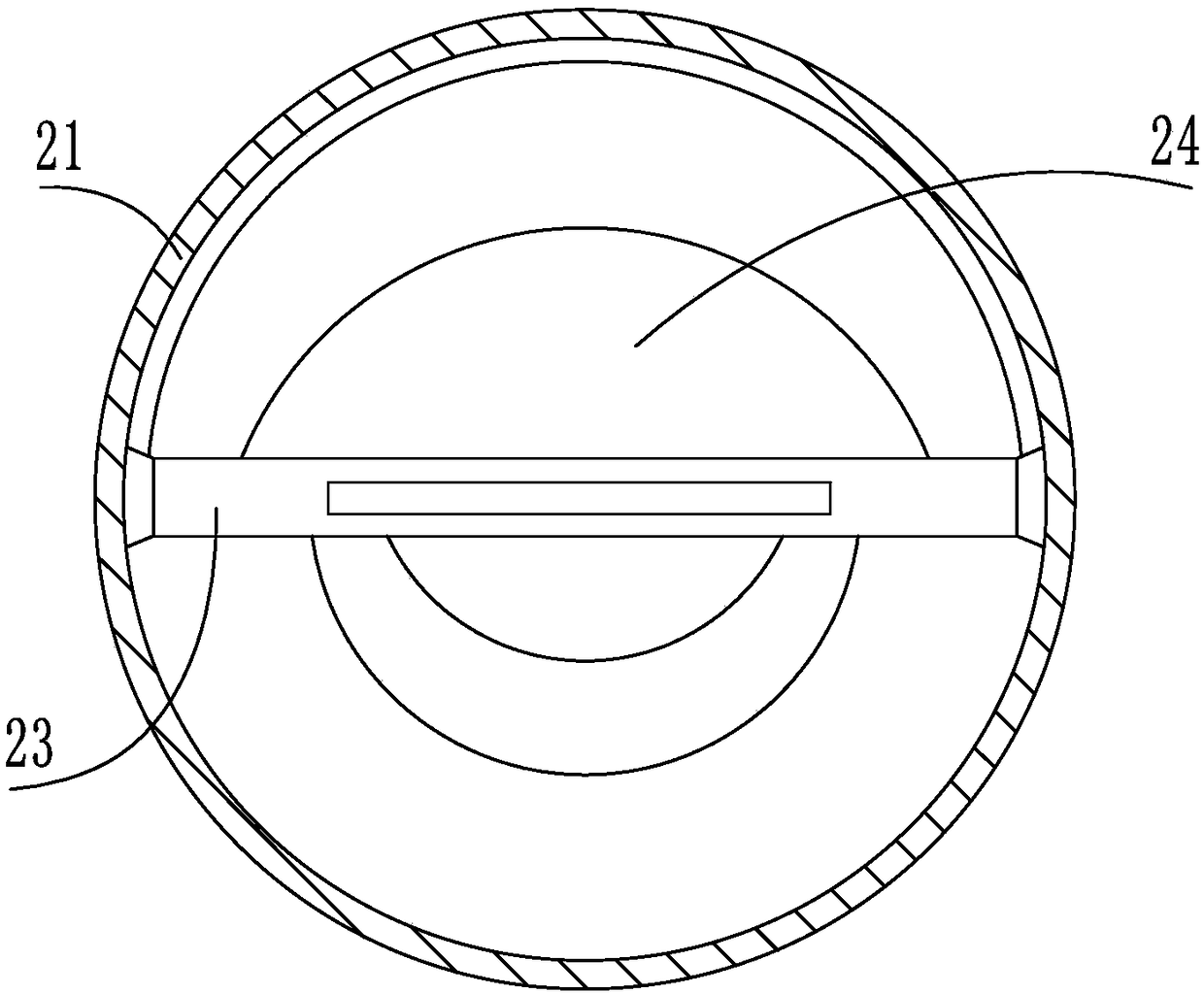

[0031] figure 1 , figure 2 and image 3 Among them, a high-efficiency dust removal equipment for textile workshops, including a vacuum cleaner 1 and a processing mechanism 4 connected through a pipe 5, the vacuum cleaner 1 includes a dust suction blade 11 and a dust accumulation cover wall 12, and one side of the dust suction blade 11 is provided with a rotating motor 111, the dust cover wall 12 is spherical, and the dust cover wall 12 is provided with a fixed frame 112 for installing the rotating motor 111, and the motor shaft of the rotating motor 111 coincides with the axis of the dust suction blade 11. The dust suction blade 11 is positioned at the inner side of the dust accumulation cover wall 12 , and the side away from the dust accumulation cover wall 12 of the dust suction blade 11 is provided with a protective net 13 cooperating wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com