Battery control unit potting structure and packaging method

A battery control and potting technology, applied in electrical components, sealed enclosures, electrical equipment enclosures/cabinets/drawers, etc., can solve problems such as the inability of the battery control unit potting structure to meet the needs, to simplify the product structure and process, reduce weight, the effect of improving potting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the purpose of the invention, technical solution and beneficial technical effects of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific implementation methods. It should be understood that the specific implementations described in this specification are only for explaining the present invention, not for limiting the present invention.

[0034] The battery control unit potting method of the present invention comprises the following steps:

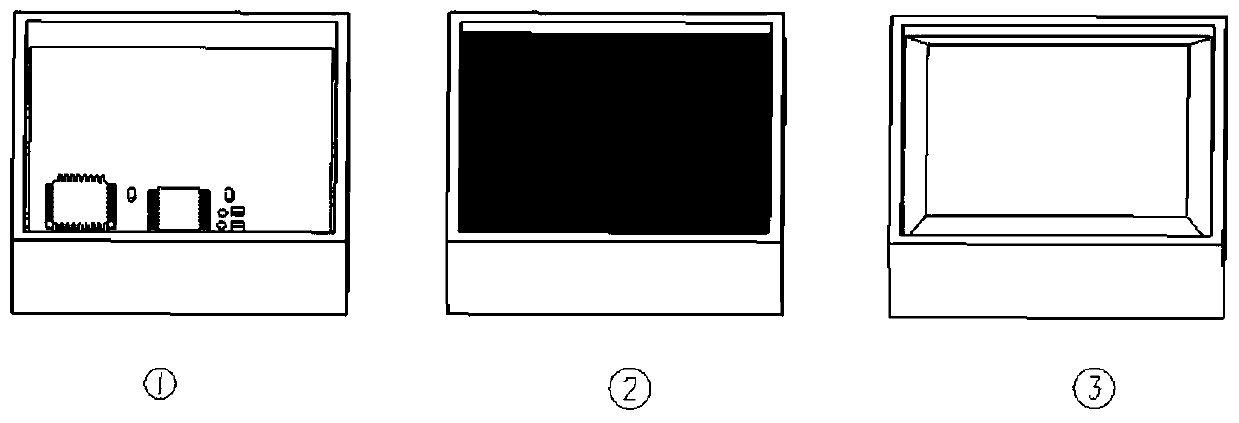

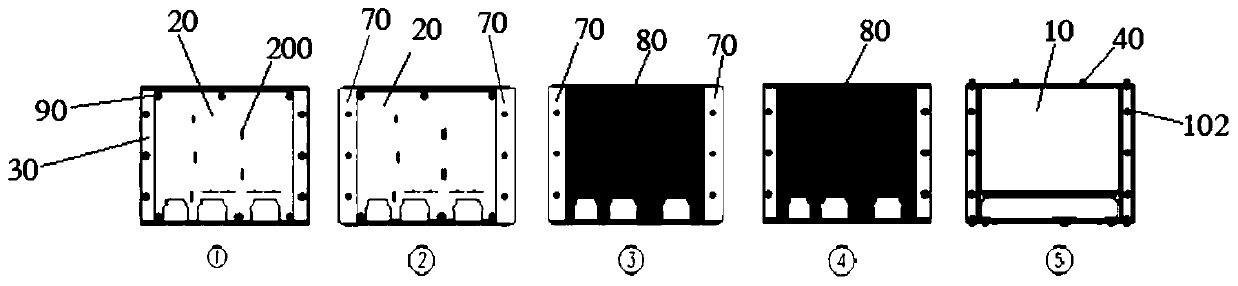

[0035] see Figure 3 to Figure 5 Shown:

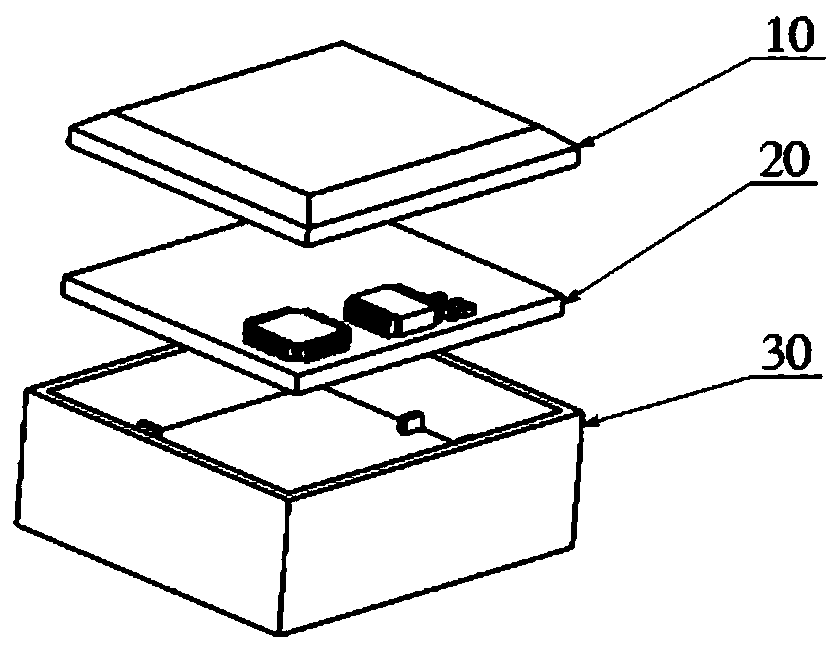

[0036] 1) Provide a bottom case 30 with at least one side open: the bottom case 30 is made of sheet metal or aluminum plate material, and can be a structure with one side, two sides, three sides or four sides open. The specifications of the internal printed circuit board 20 are adjusted so that bottom shells 30 of different specifications and shapes are formed by bending an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com