Full-automatic integrated fuel gas energy-saving high-temperature furnace

An all-in-one, fully automatic technology, used in air heaters, fluid heaters, and devices that apply liquid to surfaces to reduce heat waste, save labor, and avoid paint damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

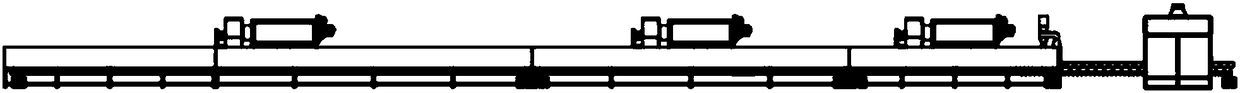

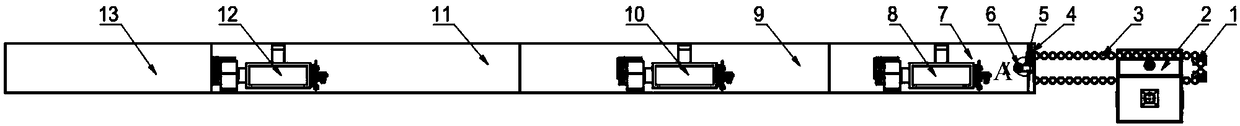

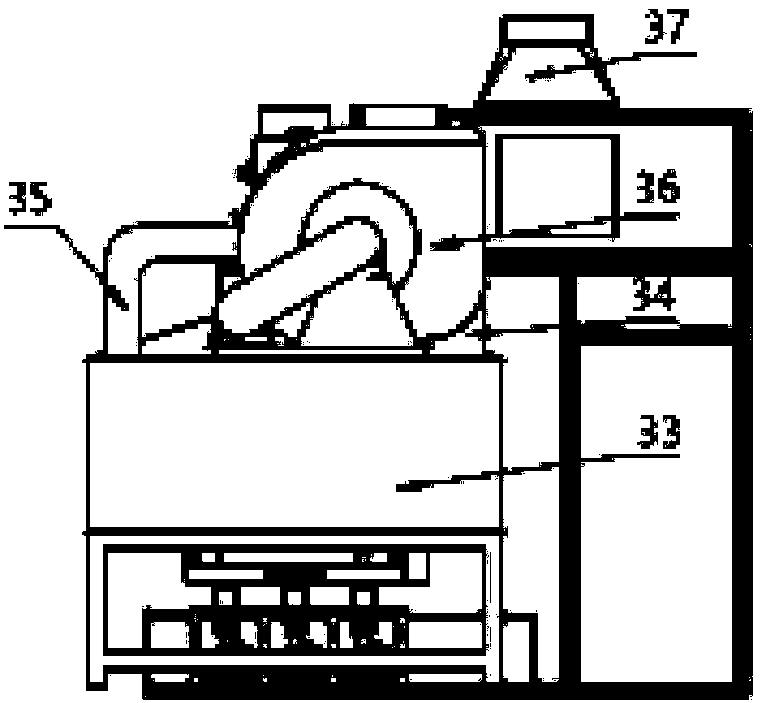

[0035] Such as Figure 1 to Figure 14 As shown, the fully automatic integrated gas-fired energy-saving high-temperature furnace of the present invention includes a ground rail chain transmission mechanism 1, a furnace mouth exhaust port 4, a furnace mouth exhaust port 5, a furnace chamber exhaust gas exhaust port 6, and a low-temperature section furnace body 7 , low temperature section combustion chamber 8, medium temperature section furnace body 9, medium temperature section combustion chamber 10, high temperature section first section furnace body 11, high temperature section combustion chamber 12, high temperature section second section furnace body 13, furnace body inlet and outlet 14, transmission Ground rail chain 15, low-temperature exhaust air outlet A16, low-temperature exhaust air outlet B17, medium-temperature exhaust air outlet A18, medium-t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com