Waterproof spindle box for machine tool

A waterproof and spindle box technology, which is applied in the direction of metal processing machinery parts, large fixed members, metal processing equipment, etc., can solve the problems of water infiltration into the spindle box, spindle and other mechanism corrosion, so as to improve the bearing capacity, reduce raw materials, reduce The effect of the use of molten metal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

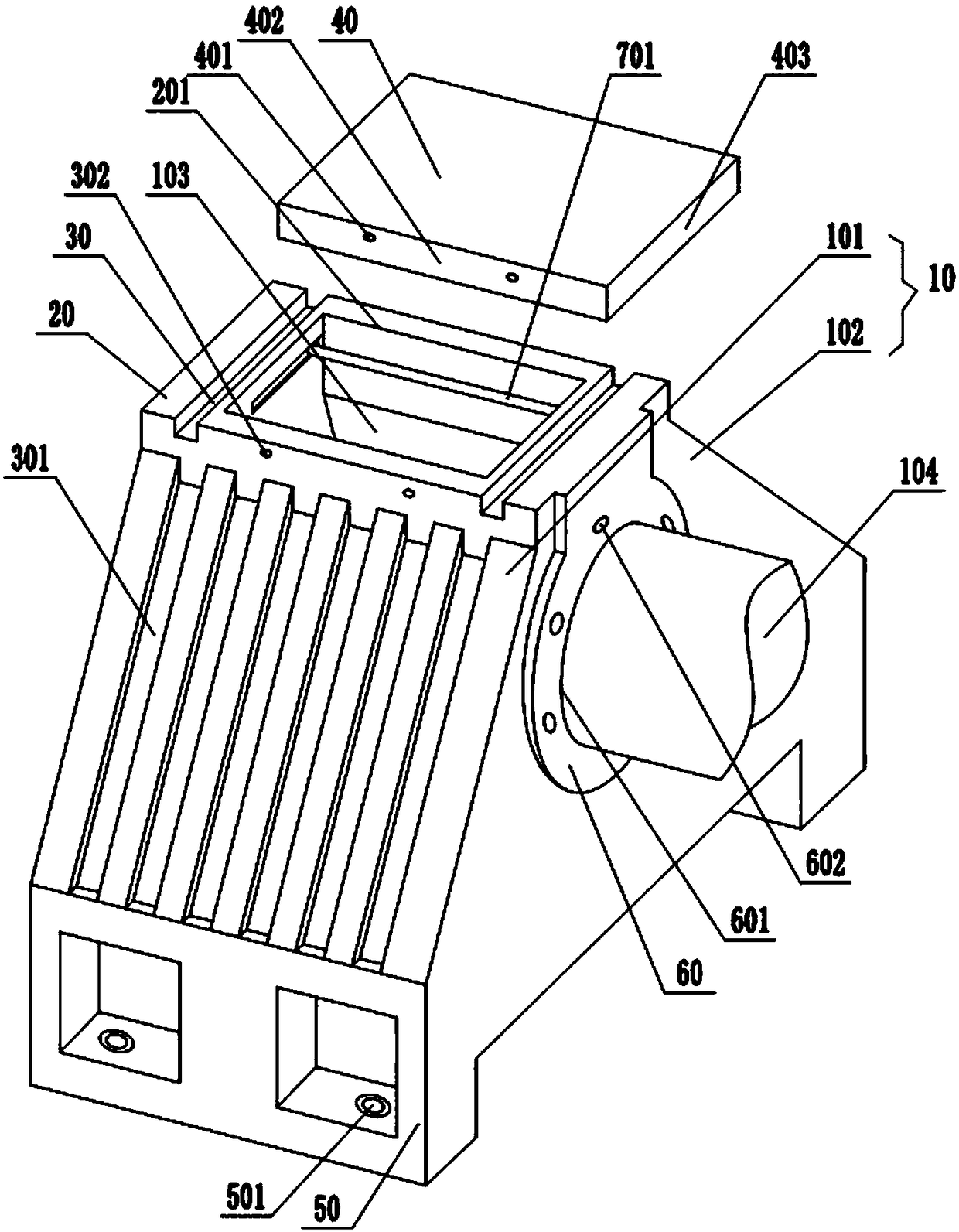

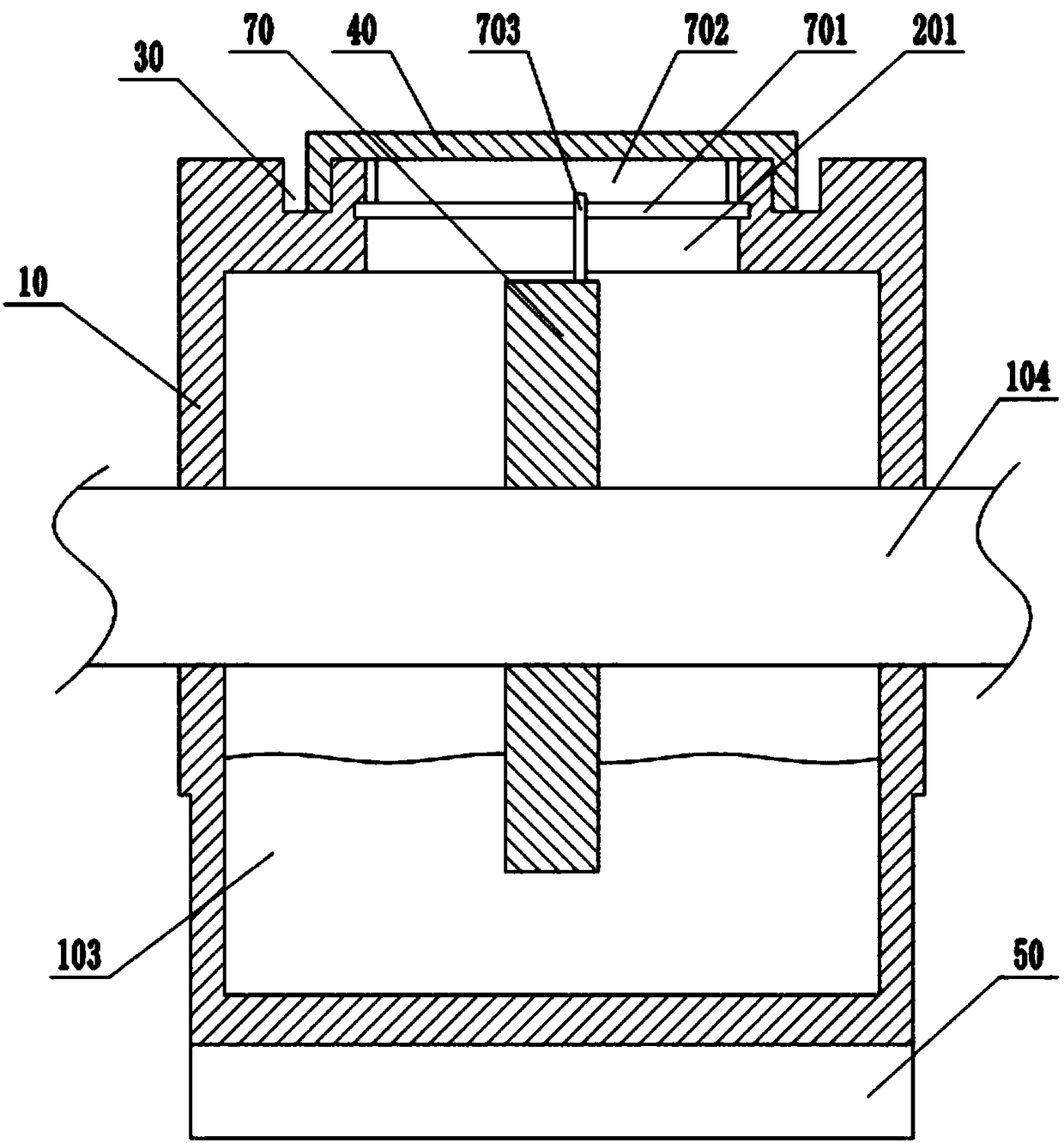

[0031] Embodiment one is basically as figure 1 and figure 2 Shown:

[0032] A waterproof headstock for machine tools, comprising a box body 10, wherein the longitudinal section of the box body 10 is a trapezoid with a narrow top and a wide bottom. The box body 10 includes two inclined surfaces 101 and two vertical surfaces 102. The top is provided with a rectangular boss 20, and a main shaft cavity 103 is provided in the box body 10, and a main shaft 104 is installed in the main shaft cavity 103, and a bearing is fixed between the main shaft 104 and the box body 10. There is an inspection hole 201 communicating with the main shaft cavity 103, wherein the inspection hole 201 is a rectangular hole.

[0033] On the rectangular boss 20, there are grooves 30 located on both sides of the inspection hole 201. On the side wall of the table 20, a plurality of diversion grooves 301 are vertically provided on the two slopes 101 of the box body 10, and the upper ends of the diversion ...

Embodiment 2

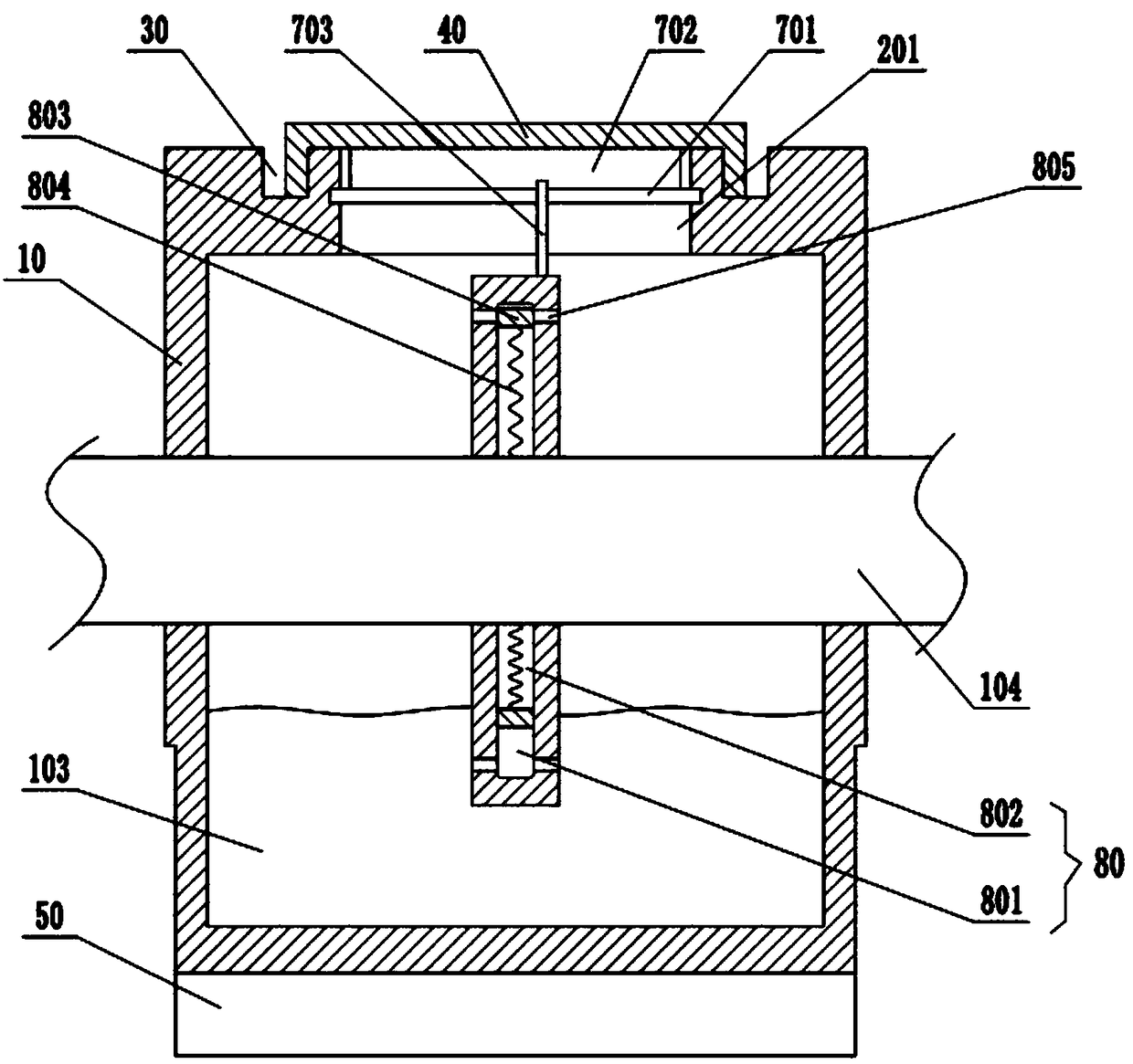

[0039] Embodiment two is basically as image 3 Shown:

[0040] The difference from Embodiment 1 is that a plurality of closed sliding chambers 80 are arranged in the oil throwing pan 70, each sliding chamber 80 is distributed around the circumference of the oil throwing pan 70, and magnetic sliding chambers 80 are slidably and sealingly connected to each other. Block 803, the sliding block 803 divides the sliding chamber 80 into an oil chamber 801 and a cavity 802, wherein the cavity 802 is close to the side of the main shaft 104, wherein the sliding block 803 is located between the side of the cavity 802 and the main shaft 104, and a second spring is fixed 804, oil holes 805 communicating with the oil chamber 801 are opened on the left and right end surfaces of the oil flinger 70. In addition, in this embodiment, the horizontal rod 701 has magnetism, and the magnetism on the opposite side of the slider 803 is opposite.

[0041] When the oil thrower 70 rotates and is immersed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com