Drilling machine

A technology for machine tools and machine tool seats, which is applied to boring/drilling, drilling/drilling equipment, and components of boring machines/drilling machines, etc., can solve the problems of unsuitability for mass production, poor machine tool stability, and low processing efficiency. Achieve the effects of good machine tool accuracy and stability, high processing efficiency, and improved processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

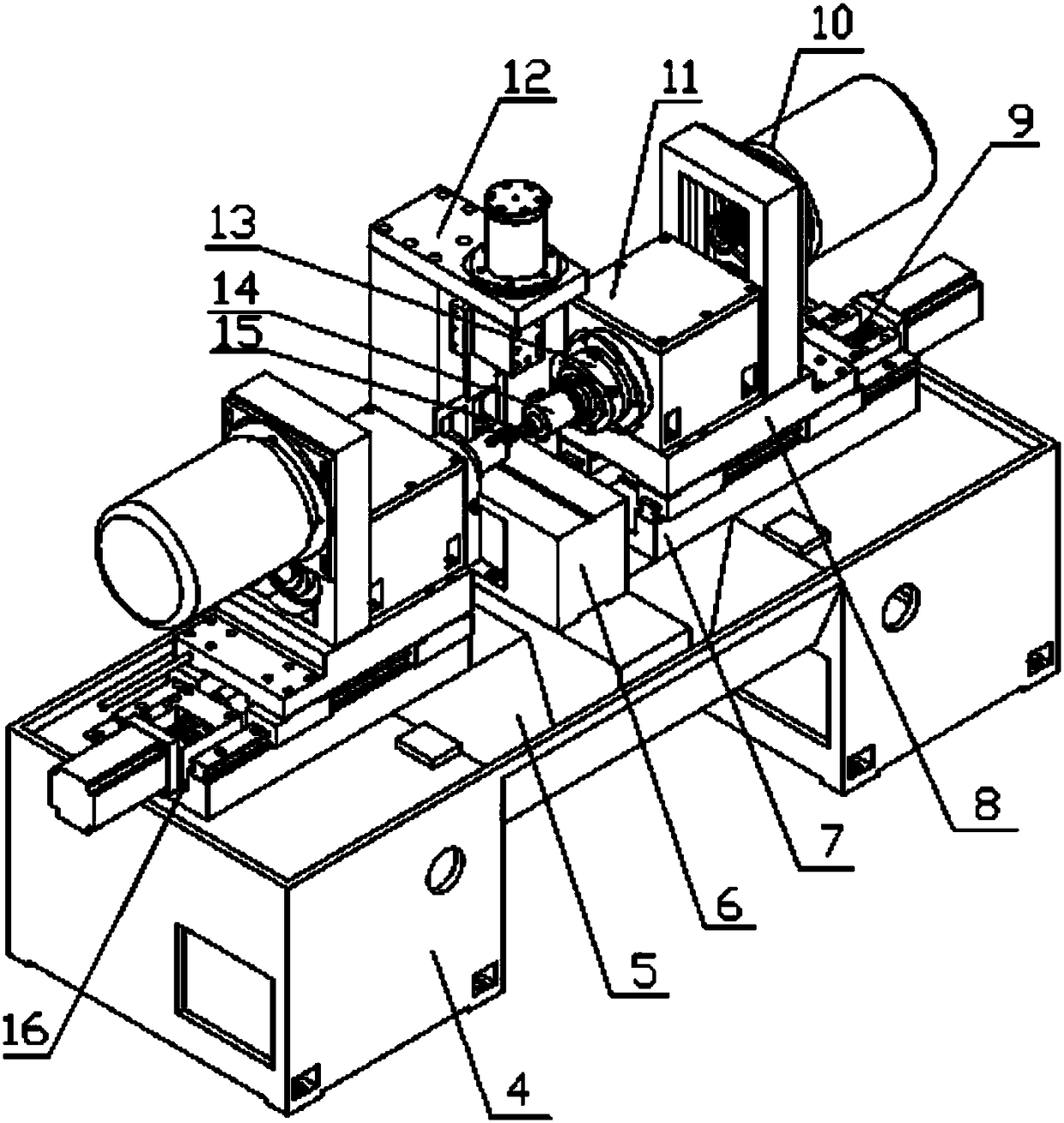

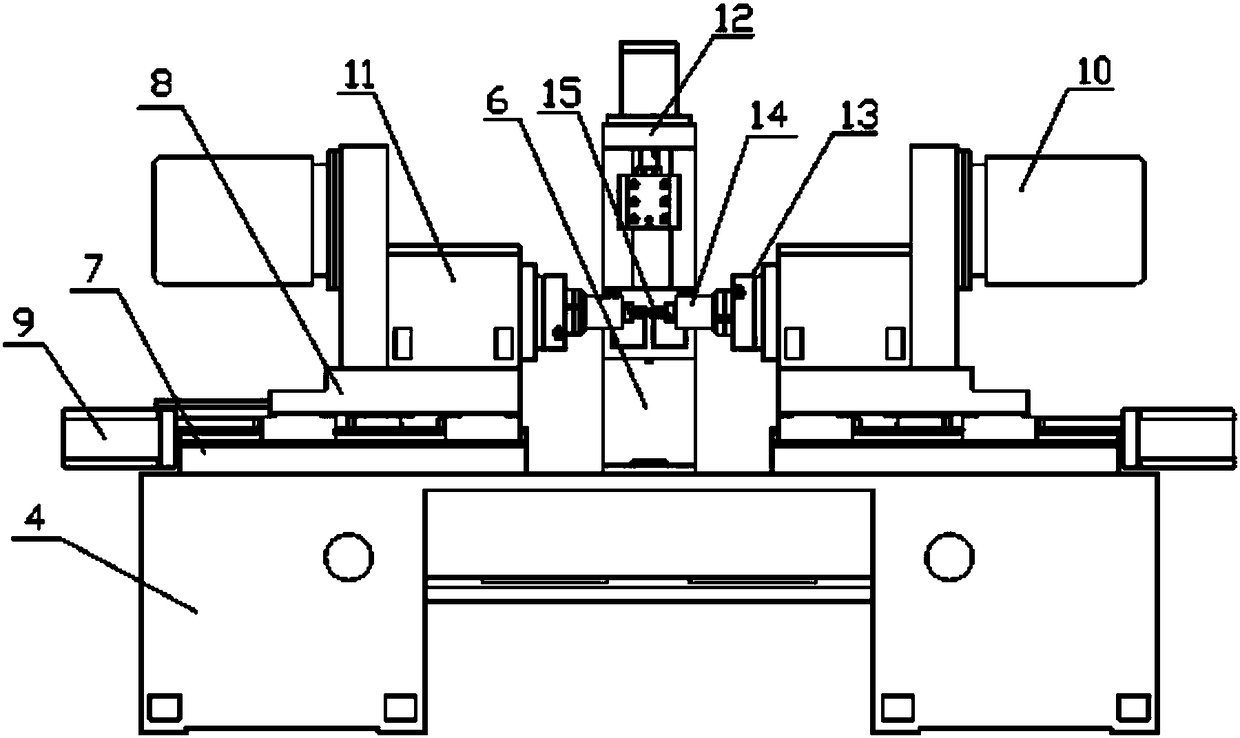

[0023] The structure of the present invention will be further described in detail below in conjunction with the accompanying drawings.

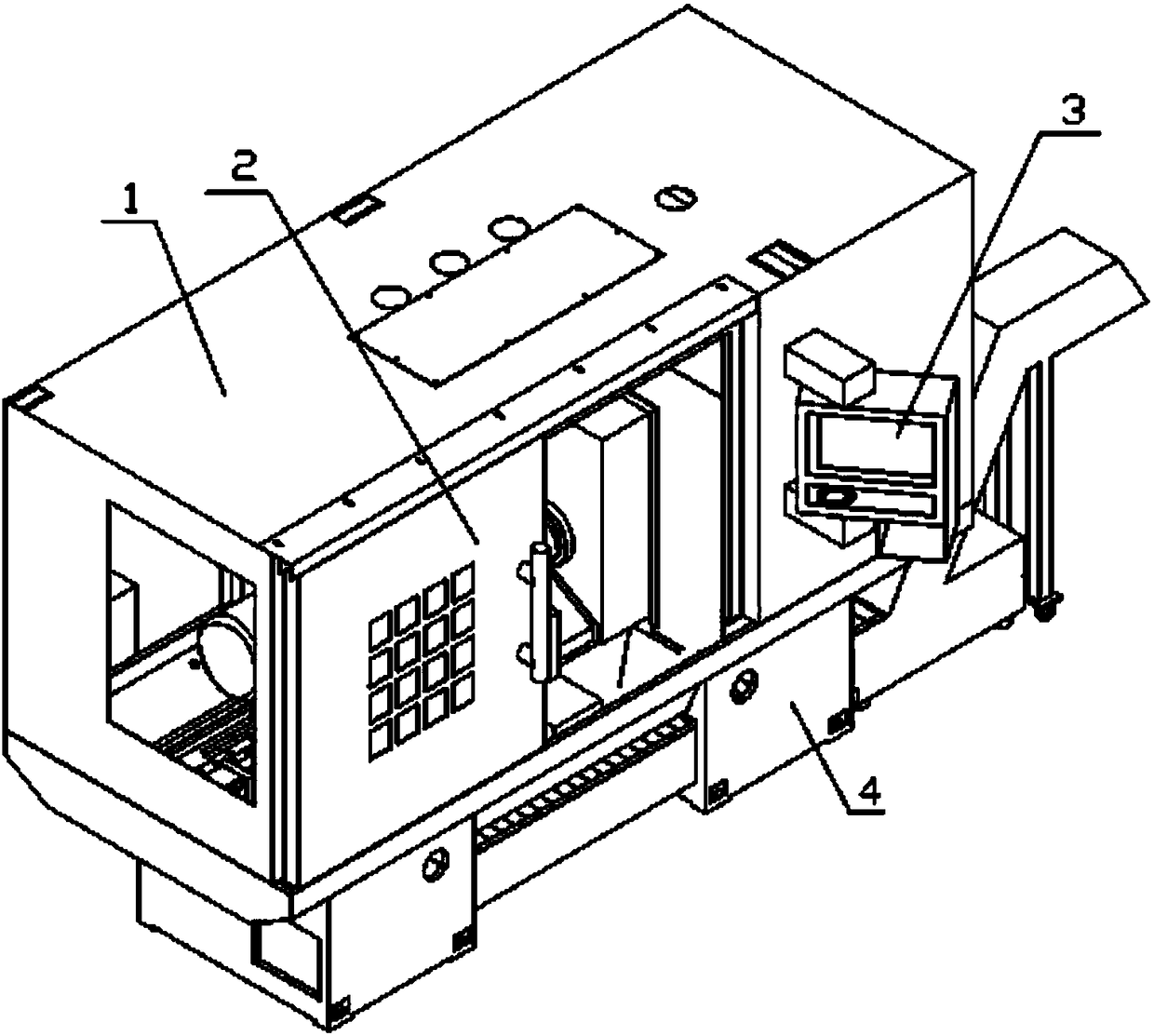

[0024] Such as figure 1 , 2 , shown in 3, a kind of vertical double-head drilling machine tool, comprises machine bed 4, workbench 6, main shaft 13, drill bit 15, and workbench 6 is installed in the middle of described machine bed 4 top surfaces, workbench 6 rear end faces connect workpiece Fixture 12, slide rails 7 are arranged symmetrically on the left and right sides of the workbench 6. There are grooves 16 inside the slide rails 7. The drive screw 9 is arranged in the groove 16, and the guide seat 8 of the headstock 11 is fixed on the top by screws. Movably connected to the slide rail 7, placed above the transmission screw 9, a main shaft 13 pierces through the headstock 11, the end of the main shaft 13 is socketed with the tool holder 14 through a three-jaw chuck, and the end of the tool holder 14 is equipped with a drill bit 15, Place...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com