Bamboo stick grinding device

A technology of bamboo sticks and abrasive tools, which is applied in the direction of grinding drive device, grinding machine, grinding feed movement, etc., can solve the problems of low grinding efficiency, high labor intensity, low efficiency, etc., so as to improve grinding efficiency and reduce labor intensity. , the effect of uniform diameter of bamboo sticks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

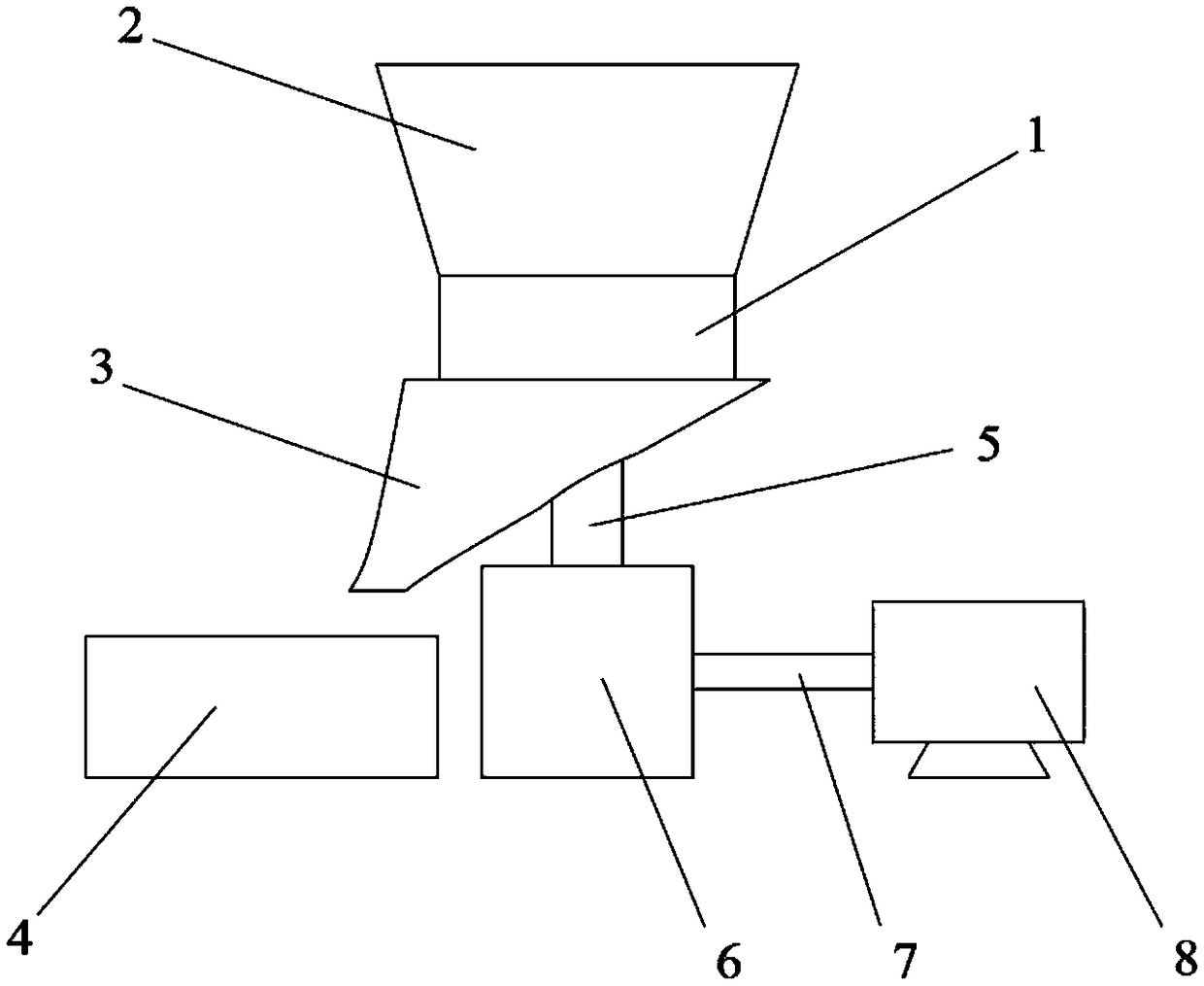

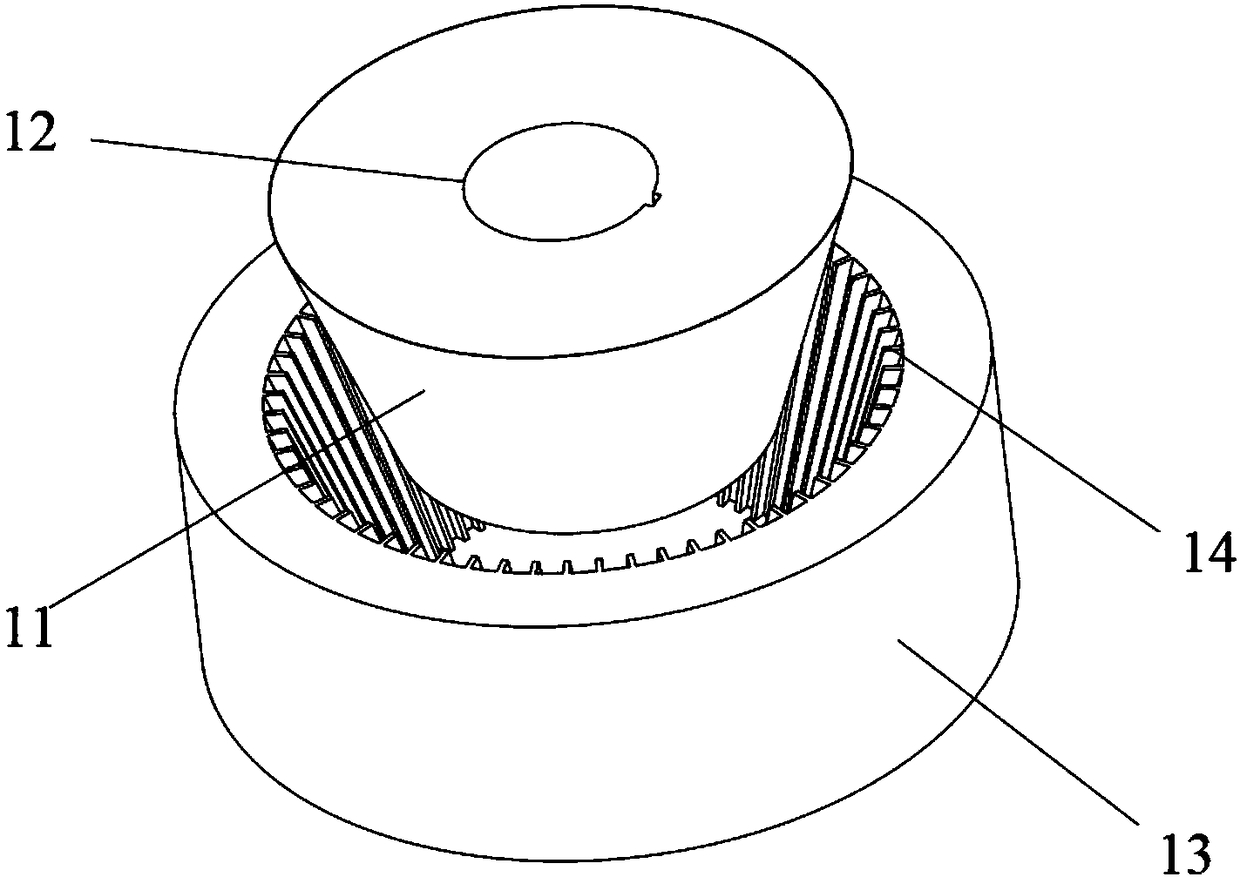

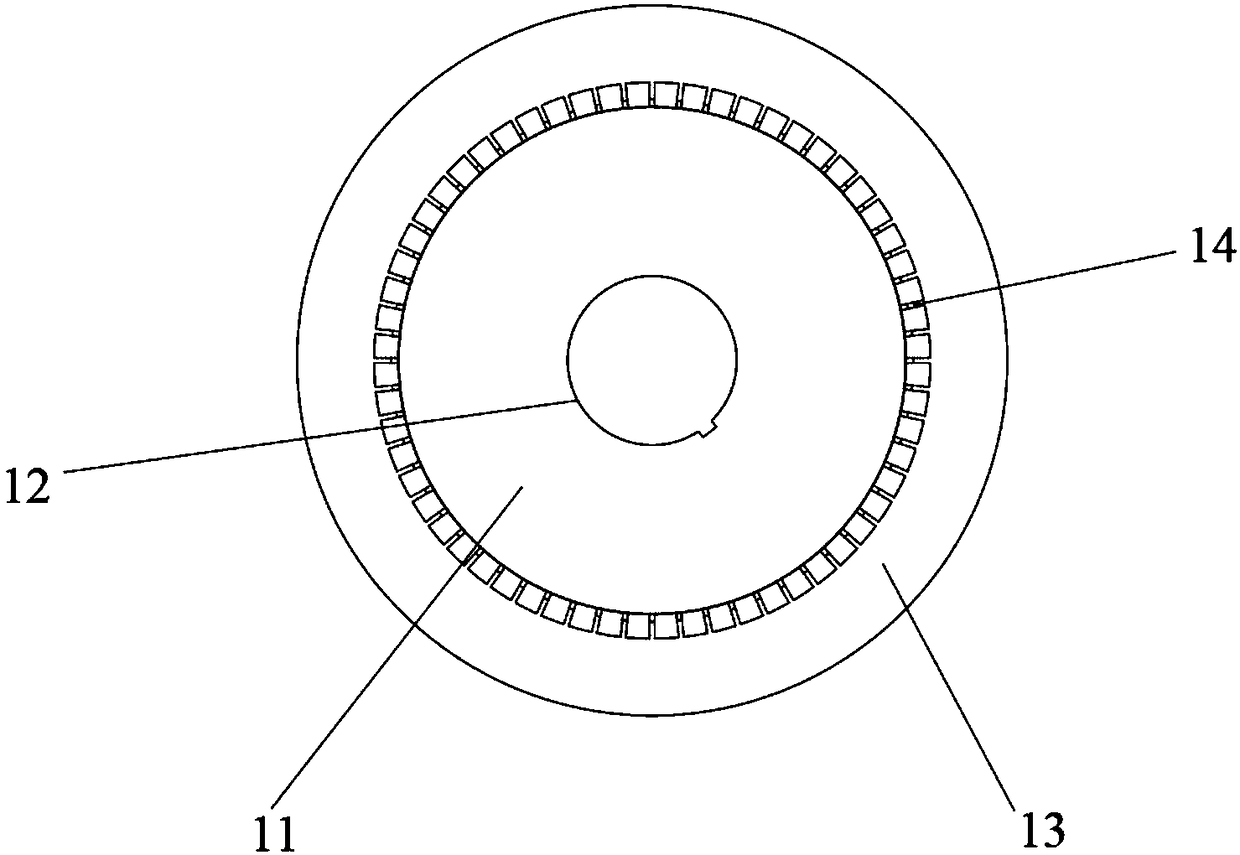

[0014] Example. A kind of bamboo stick polishing device, constitutes as Figure 1-4 As shown, it includes the abrasive tool 1, the upper part of the abrasive tool 1 is connected with the feed port 2, and the lower part of the abrasive tool 1 is connected with the funnel 3; the shape of the funnel 3 is an oblique cone, including the funnel wall 31, and the lower left side of the funnel wall 31 is provided with a discharge port 32. A sleeve 33 is also provided on the funnel wall 31, and a collection box 4 is provided below the discharge port 32; a vertical rotating shaft 5 and a clutch 6 are sequentially connected to the bottom of the abrasive tool 1, and a horizontal rotating shaft 7 is sequentially connected to the right side of the clutch 6 And the motor 8; the abrasive tool 1 includes a conical t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap