Clamping device for woodworking five-axis machining

A clamping and woodworking technology, which is applied in the field of woodworking five-axis processing worktables, can solve the problems of unreasonable design, single function, and complex structure of five-axis machine tool worktables, and achieve complete functions, various methods, and simple and reasonable design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

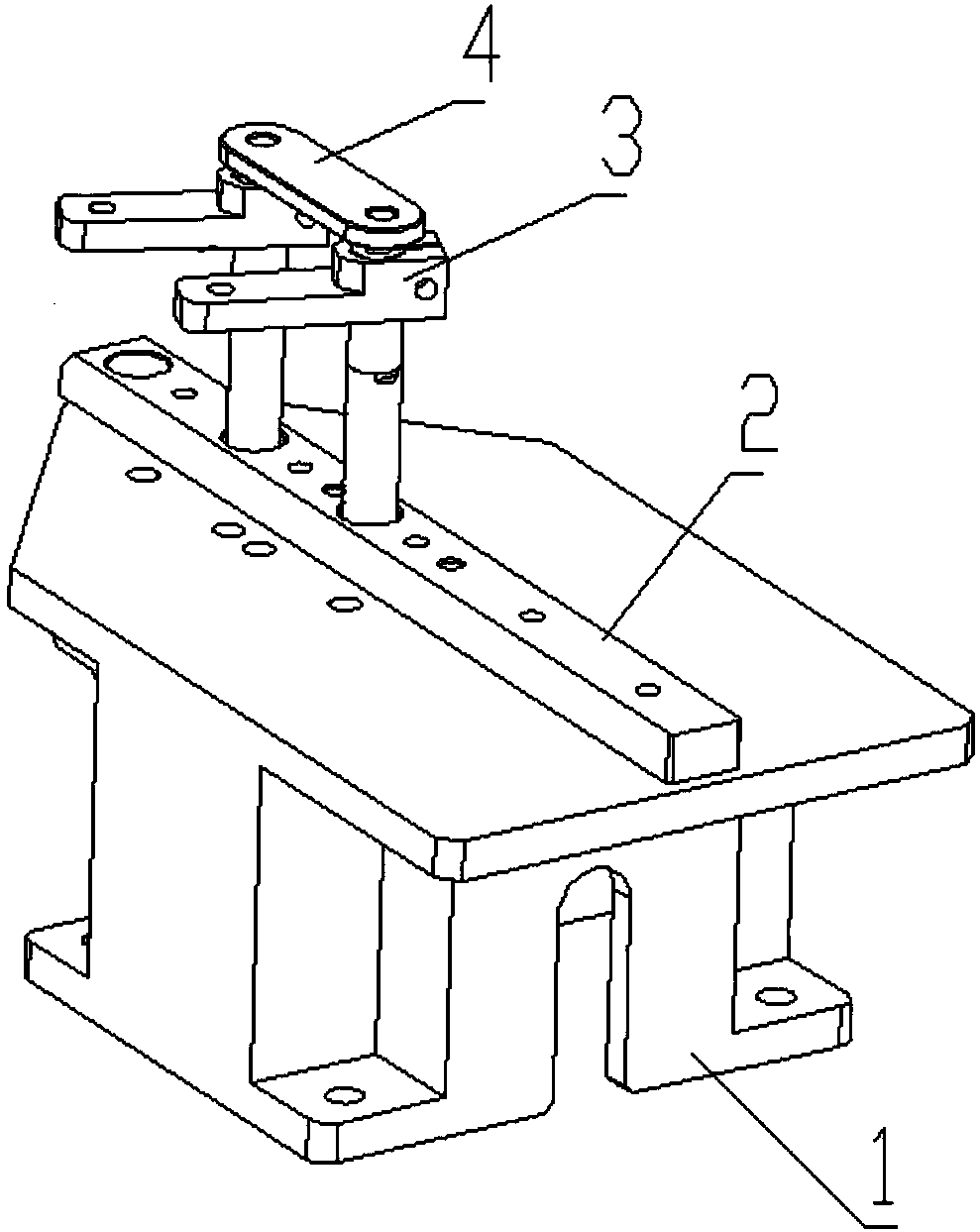

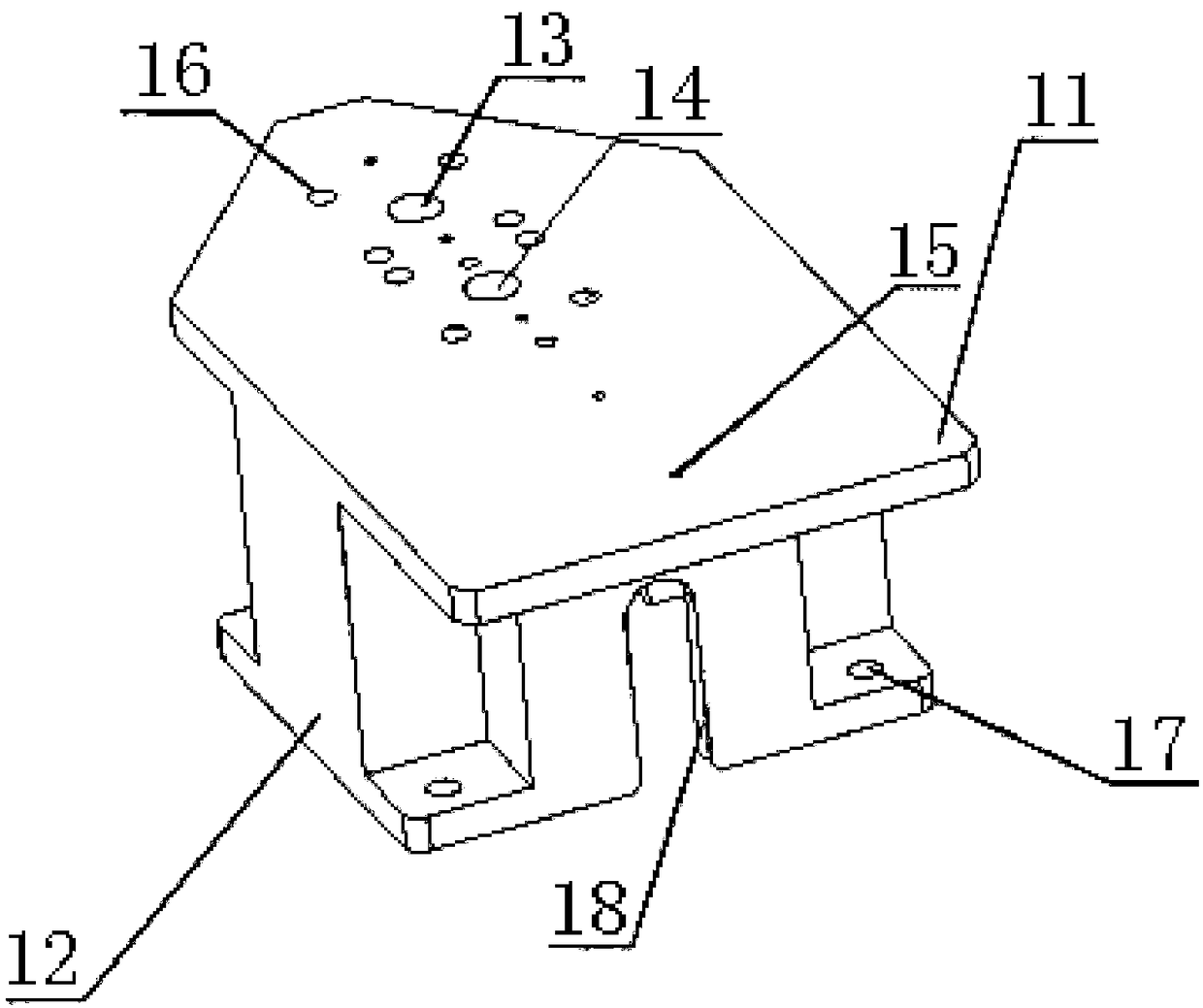

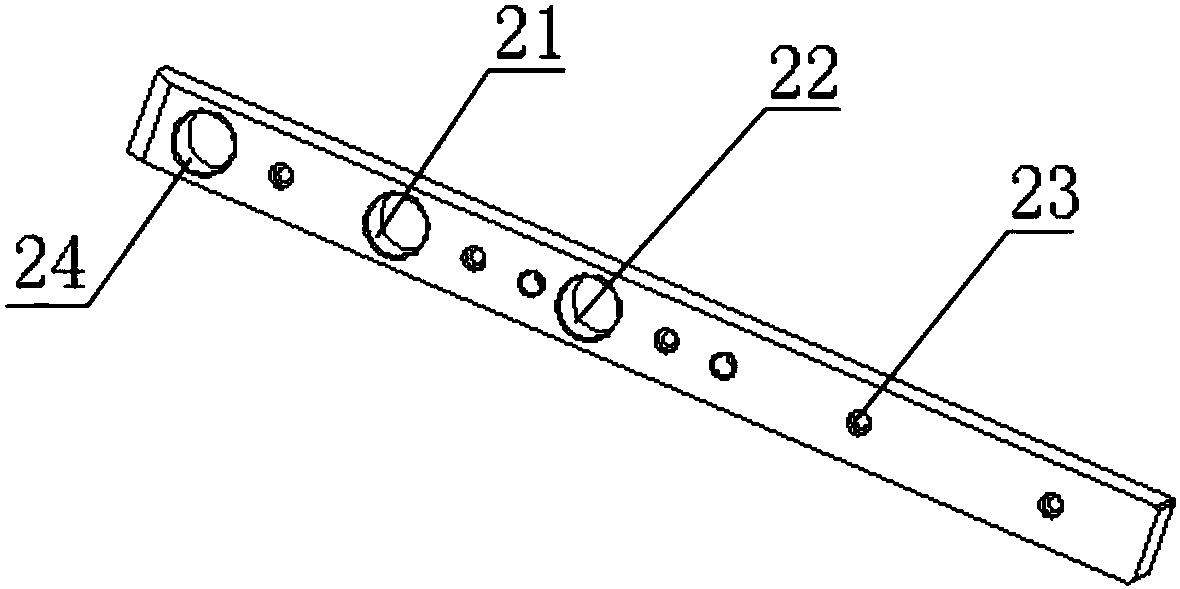

[0034] Embodiment one: see Figure 1-7 As shown, a clamping device for woodworking five-axis processing, including a positioning base 2 installed on the workbench 1, and at least one set of pressing mechanism 3 arranged on the positioning base 2, said The pressing mechanism 3 includes a driving cylinder 31 and a pressing handle 33. The driving cylinder 31 is located below the workbench 1. According to the degree of freedom of the installation hole on the seat 2, one end of the pressing handle 33 is sleeved on the top of the telescopic rod 32 through the locking hole 36, and the other end is matched with the wood block to be processed, and the pressing handle 33 passes through the The movement of the telescopic rod 32 obtains the degree of freedom to move to the side of the workbench 1. The device has a simple structure and a reasonable design. The parts and parts and the wood are adjusted and fixed by bolts. There are various methods, which are simple and feasible. One end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com