Water-cooling injection mold

An injection mold and water-cooling technology, which is applied in the field of auto parts, can solve the problems of increasing the risk of pipeline failure, occupying workshop space, and reducing cooling speed, so as to reduce the occupied space, reduce the use of pipelines, and promote evaporation.

Inactive Publication Date: 2018-09-28

CHONGQING YINSHENG MOLD

View PDF5 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The hot water discharged from the pipeline needs to be sent to another storage device for cooling, so the production workshop needs to lay water inlet and outlet pipes connected to each machine tool. There are many pipelines in the workshop, which will increase the space occupied by the workshop. Risk of Pipeline Failure

Secondly, the pipe is generally cylindrical, and the contact area between the cylindrical pipe and the mold is small, and the heat on the mold is transferred to the water in the pipe at a slower speed, which will also reduce the cooling rate

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

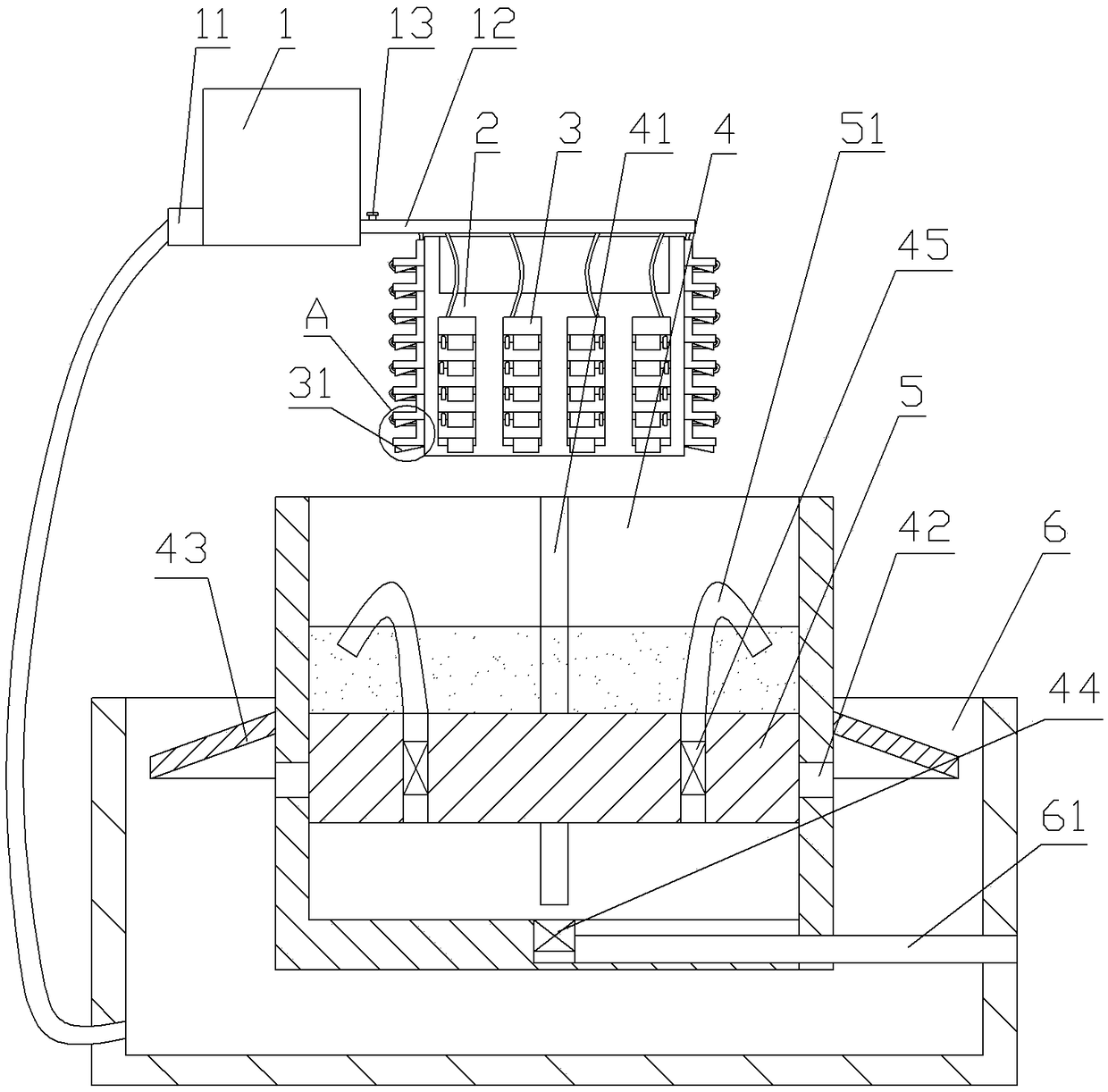

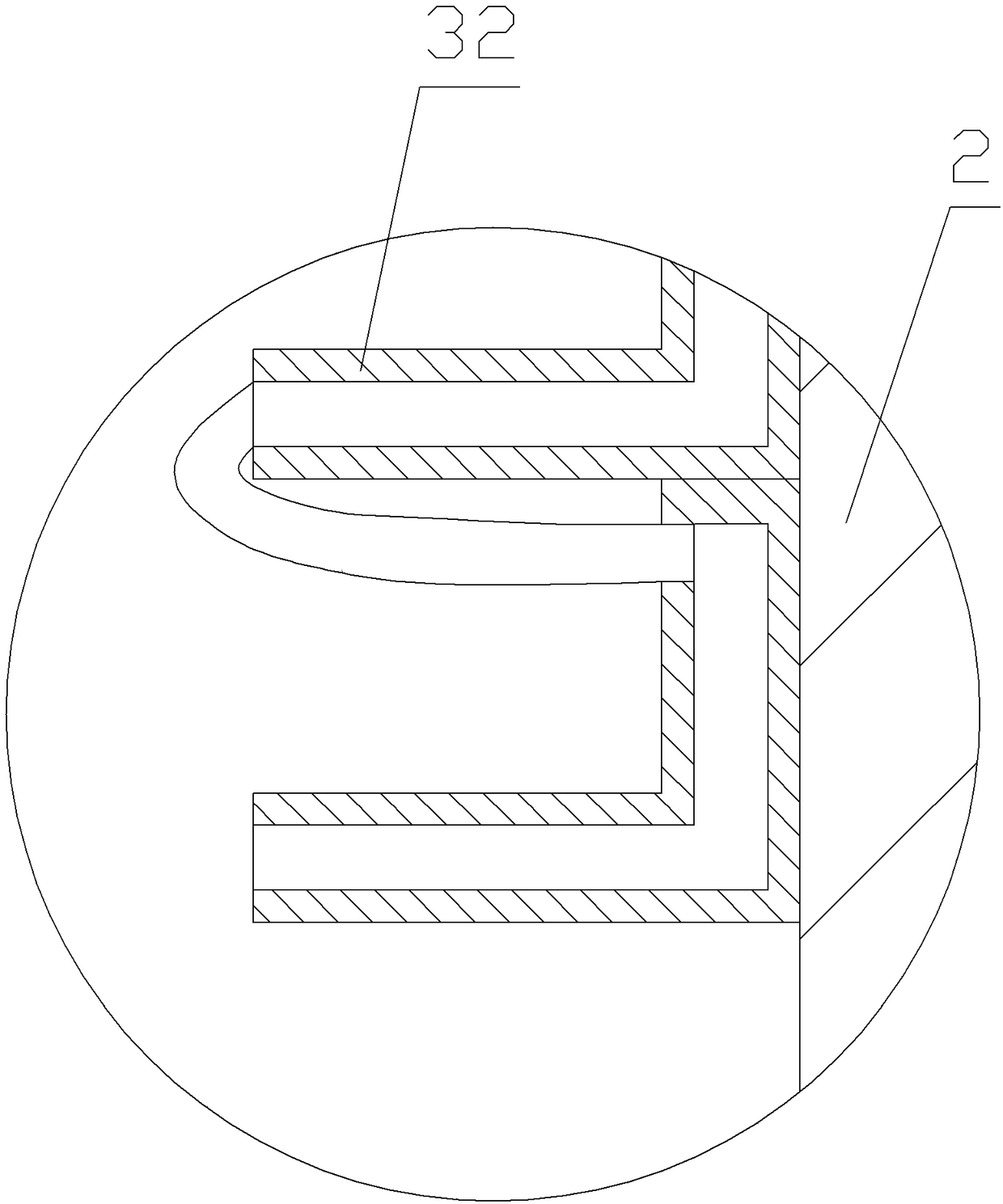

The invention relates to the field of auto parts and specifically discloses a water-cooling injection mold. The water-cooling injection mold comprises a rack, a cooling pipe, a water tank, a mold bodyand a heat radiation mechanism. A water pump is fixed on the water tank. The mold body and the water tank are both fixed on the rack. The water tank is communicated with the cooling pipe. The heat radiation mechanism comprises a cylinder, a piston and a sink of the cylinder. The cylinder is fixed on the rack, the side wall of the cylinder is provided with a water outlet, and total water yield ofthe water outlet is greater than total water inflow of the cooling pipe. An air inlet check valve is fixed at the lower part of the cylinder. A spring is disposed inside the cylinder. The piston and the bottom of the cylinder are both fixed with a magnet. The piston is positioned above the air inlet check valve, and the piston is provided with an air outlet assembly. The air outlet assembly comprises an air outlet pipe and an air outlet check valve. The air outlet check valve is communicated with the cylinder. An air outlet end of the air outlet check valve is communicated with the cylinder. An air outlet end of the air outlet check valve is communicated with the air outlet pipe, and the upper part of the air outlet end is bent to be arch-shaped. The sink is communicated with a water inletend of the water pump. By the scheme, the quantity of water inlet pipes in a workshop which are communicated with the outside world can be reduced.

Description

technical field [0001] The invention relates to the field of auto parts, in particular to an injection mold for auto parts. Background technique [0002] Injection molding is a method of producing shapes for industrial workpieces, usually using rubber injection molding or plastic injection molding. Using injection molding machines to make thermoplastic or thermosetting materials into plastic products of various shapes using plastic molding molds, it is mainly used to manufacture various workpieces with complex structures or small volumes. The current mold generally includes a movable mold and a fixed mold that can be separated from each other. In the cavity, and then the mold is cooled, and the molten raw material is cooled and gradually solidified, and finally forms the same workpiece as the mold. [0003] The current injection molds are generally water-cooled, and a pipe for cold water to pass is arranged around the mold. The temperature of the raw material is lowered a...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B29C45/73

CPCB29C45/73B29C45/7312

Inventor 邱建华

Owner CHONGQING YINSHENG MOLD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com