Anti-fog glass and manufacturing method thereof

A technology of anti-fog glass and a manufacturing method, which is applied in the field of anti-fog and can solve the problems such as the inability of continuous anti-fog of glass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

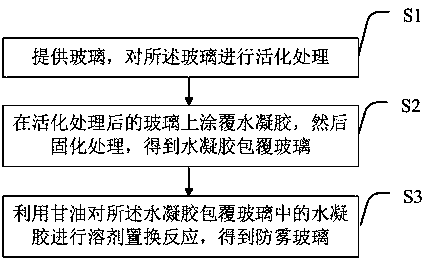

[0025] In the preparation method of the anti-fog glass provided by the present invention, the glass is activated first, and then the activated glass is coated with hydrogel, and the surface of the activated glass can be more easily and firmly bonded with the hydrogel. Combine, and then use glycerin to replace the solvent (ie water) in the hydrogel, thereby forming a gel-glycerin anti-fog film combined on the glass surface, which can effectively perform anti-fog effect for a long time.

[0026] In the step S1, glass is firstly provided, and the glass may be a mirror, spectacle lens, automobile reflector, window glass, optical instrument glass, etc. Considering that the glass surface is unclean due to dust or grease pollution, which is not conducive to the adhesion and bonding of hydrophilic hydrogels, it is necessary to clean and activate the glass before coating the hydrogels. Preferably, the plasma is used to treat the The glass is cleaned and activated, that is, the glass is...

Embodiment 1

[0036] Preparation of ammonium persulfate solution: Dissolve 0.01 g of ammonium persulfate in 1 mL of ultrapure water to obtain ammonium persulfate solution;

[0037] Prepare calcium sulfate solution: dissolve 0.032g calcium sulfate dihydrate in 6mL ultrapure water to obtain calcium sulfate solution;

[0038] Preparation of hydrogel: Add 0.5g sodium alginate and 4g acrylamide into 25mL ultrapure water, mix well, then take 15mL, add 60uL of the ammonium persulfate solution and 4mL of the calcium sulfate solution, mix to obtain Hydrogels;

[0039] Preparation of anti-fog glass: Treat the glass with plasma for 3 minutes in advance, then coat a layer of the hydrogel on the surface of the glass, and treat it under ultraviolet irradiation for 40 minutes to obtain the hydrogel-coated glass; The coated glass is completely soaked in glycerin for 3 hours, and then taken out to obtain the anti-fog glass;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com