PET flash material and preparation method thereof

A flashing material and mirror ink technology, which is applied in ink, household utensils, applications, etc., can solve the problems of heavy color of bronzing layer, dazzling pearl layer, low ornamental value, etc., and achieve uniform gloss, high compatibility, good Transparency and Refractive Index Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

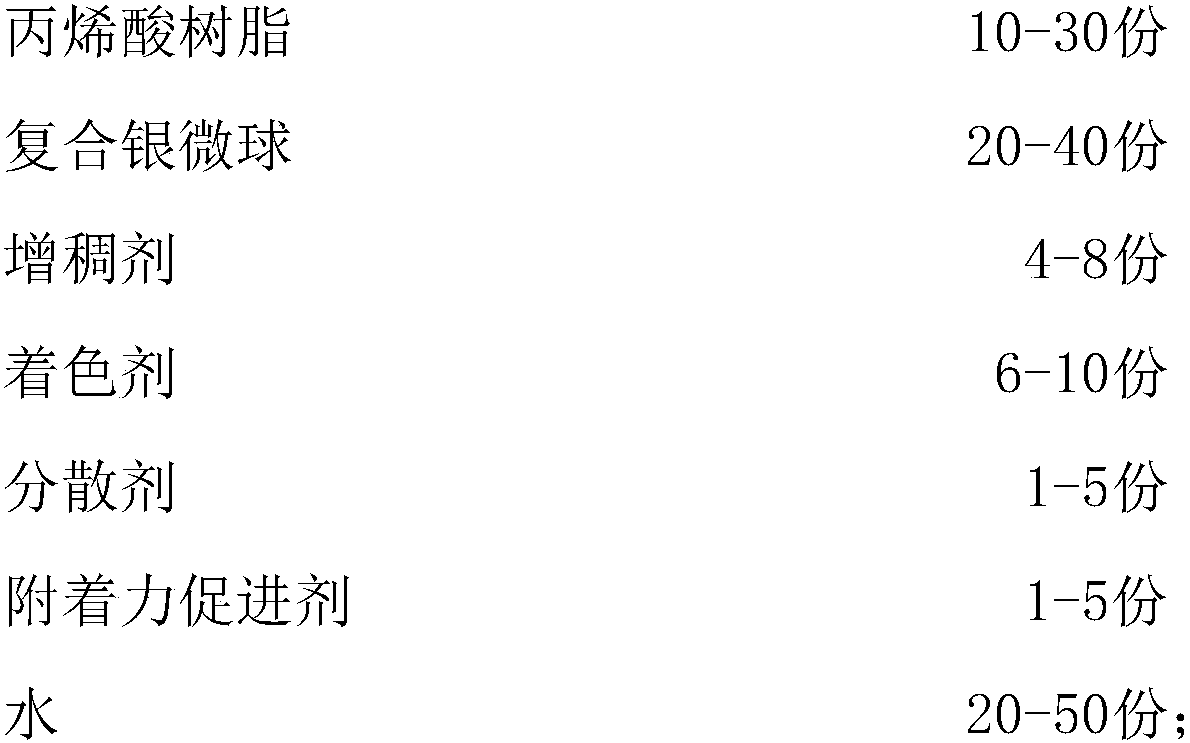

[0028] A PET glitter material, comprising a PET sheet and a mirror layer compounded on the outer surface of the PET sheet. The mirror layer is formed of a mirror ink. The mirror ink includes the following raw materials in parts by weight:

[0029]

[0030]

[0031] The composite silver microsphere is a core-shell structured microsphere, the core is a mixture of silver particles and calcium carbonate powder, and the shell is polyacrylamide.

[0032] Wherein, the preparation method of the composite silver microsphere includes the following steps:

[0033] (1) Use acrylic amide as the solute and N-N dimethylformamide as the solvent, and configure a precursor solution with a solution concentration of 20 wt%;

[0034] (2) After dispersing and mixing the silver particles and calcium carbonate powder in a weight ratio of 1:1, add them to the precursor solution and stir evenly to obtain a suspension;

[0035] (3) The suspension is electrostatically sprayed to obtain the composite silver microsp...

Embodiment 2

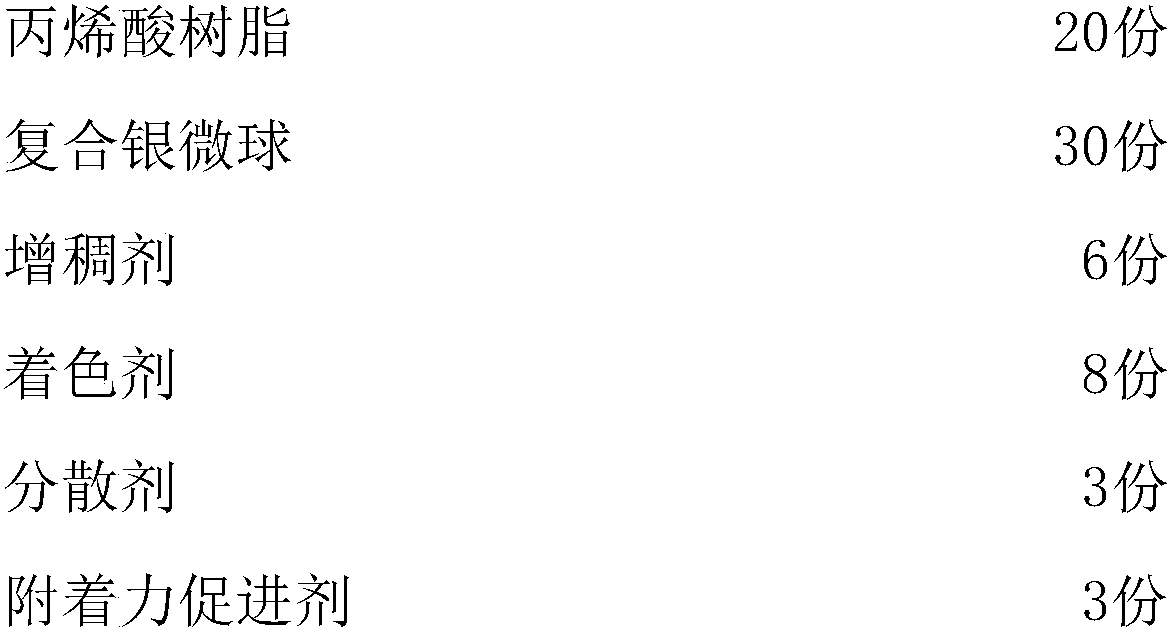

[0045] A PET glitter material, comprising a PET sheet and a mirror layer compounded on the outer surface of the PET sheet. The mirror layer is formed of a mirror ink. The mirror ink includes the following raw materials in parts by weight:

[0046]

[0047] The composite silver microsphere is a core-shell structured microsphere, the core is a mixture of silver particles and calcium carbonate powder, and the shell is polyacrylamide.

[0048] Wherein, the preparation method of the composite silver microsphere includes the following steps:

[0049] (1) Use acrylic amide as the solute and N-N dimethylformamide as the solvent, and configure a precursor solution with a solution concentration of 15 wt%;

[0050] (2) After dispersing and mixing the silver particles and calcium carbonate powder in a weight ratio of 1:2, add them to the precursor solution and stir evenly to obtain a suspension;

[0051] (3) The suspension is electrostatically sprayed to obtain the composite silver microspheres.

[...

Embodiment 3

[0061] A PET glitter material, comprising a PET sheet and a mirror layer compounded on the outer surface of the PET sheet. The mirror layer is formed of a mirror ink. The mirror ink includes the following raw materials in parts by weight:

[0062]

[0063] The composite silver microsphere is a core-shell structured microsphere, the core is a mixture of silver particles and calcium carbonate powder, and the shell is polyacrylamide.

[0064] Wherein, the preparation method of the composite silver microsphere includes the following steps:

[0065] (1) Use acrylic amide as the solute, N-N dimethylformamide as the solvent, and configure a precursor solution with a solution concentration of 15-25 wt%;

[0066] (2) After dispersing and mixing the silver particles and calcium carbonate powder in a weight ratio of 2:2, add them to the precursor solution and stir evenly to obtain a suspension;

[0067] (3) The suspension is electrostatically sprayed to obtain the composite silver microspheres.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com