Polymembrane emulsified modified fiber for drilling fluid and preparation method thereof

A technology of modified fiber and polyfilm agent, which is applied in the preparation of polyfilm emulsified modified fiber for drilling fluid, and in the field of polyfilm emulsified modified fiber for drilling fluid, which can solve the problem of poor performance in stabilizing the well wall and protecting the reservoir , Inability to effectively reduce seepage and other problems, achieve good seepage reduction effect, solve poor oil layer protection performance, and achieve good protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

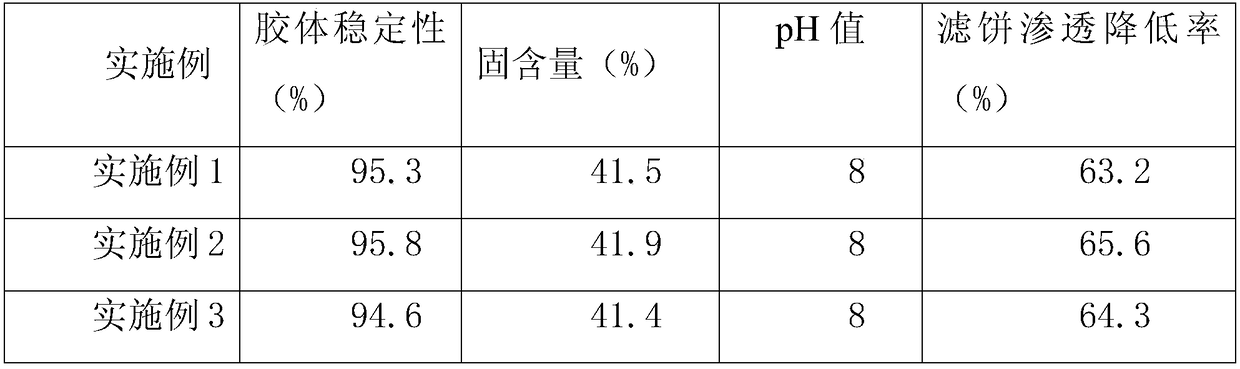

Embodiment 1

[0020] Embodiment 1: The polyfilm agent emulsified modified fiber for drilling fluid of the present invention is made of the following raw materials in weight ratio: 15 parts of styrene, 20 parts of butyl acrylate, 1 part of initiator, emulsifier 6 parts, 15 parts of water-based epoxy resin, 30 parts of water-soluble fiber, 35 parts of clear water; Described initiator is the combination (composition) of two kinds of raw materials of potassium persulfate and sodium persulfate, potassium persulfate and sodium persulfate The weight ratio is 1: 1.5; Described emulsifier is the combination (composition) of two kinds of raw materials of NP-10 emulsifier and TX-10 emulsifier, the weight of NP-10 emulsifier and TX-10 emulsifier The ratio is 1:1.5.

[0021]The preparation method of the polymembrane agent emulsified modified fiber for drilling fluid includes the following process steps: ① Preparation of emulsion: add styrene and butyl acrylate into the reaction kettle according to the a...

Embodiment 2

[0022] Embodiment 2: the polymembrane agent emulsified modified fiber for drilling fluid of the present invention is made of the raw materials of following weight ratio: 18 parts of styrene, 25 parts of butyl acrylate, 2 parts of initiator, emulsifier 5 parts, 13 parts of water-based epoxy resin, 25 parts of water-soluble fiber, 30 parts of clear water; the described initiator is potassium persulfate; the described emulsifier is TX-10 emulsifier.

[0023] The preparation method of the polymembrane agent emulsified modified fiber for drilling fluid includes the following process steps: ① Preparation of emulsion: add styrene and butyl acrylate into the reaction kettle according to the above weight ratio, slowly heat to 85 ° C, start stirring (stirring rate is 70-80r / min), then add initiator to carry out emulsion polymerization reaction, the emulsion polymerization reaction time is 2.5h, the temperature is 85 ℃, and finally the emulsion is completely cooled to room temperature; :...

Embodiment 3

[0024] Embodiment 3: The polymembrane agent emulsified modified fiber for drilling fluid of the present invention is made of the following raw materials in weight ratio: 20 parts of styrene, 30 parts of butyl acrylate, 3 parts of initiator, emulsifier 3 parts, 10 parts of water-based epoxy resin, 20 parts of water-soluble fiber, 25 parts of clear water; the described initiator is sodium persulfate; the described emulsifier is two raw materials of NP-10 emulsifier and TX-10 emulsifier The combination (composition), the weight ratio of NP-10 emulsifier and TX-10 emulsifier is 1:2.

[0025] The preparation method of the polymembrane agent emulsified modified fiber for drilling fluid includes the following process steps: ① Preparation of emulsion: add styrene and butyl acrylate into the reaction kettle according to the above weight ratio, slowly heat to 90 ° C, start stirring (stirring rate is 50-65r / min), then add initiator to carry out emulsion polymerization reaction, the emuls...

PUM

| Property | Measurement | Unit |

|---|---|---|

| colloidal stability | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com