Steel pipe, raw materials and manufacturing method thereof, and drill rod for rotary drilling rig

A production method and technology of steel pipes, which are applied in the direction of drill pipes, earthwork drilling, drilling pipes, etc., can solve the problems of low yield strength of steel pipes, and achieve the effects of improving yield strength, increasing hardenability, and good welding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

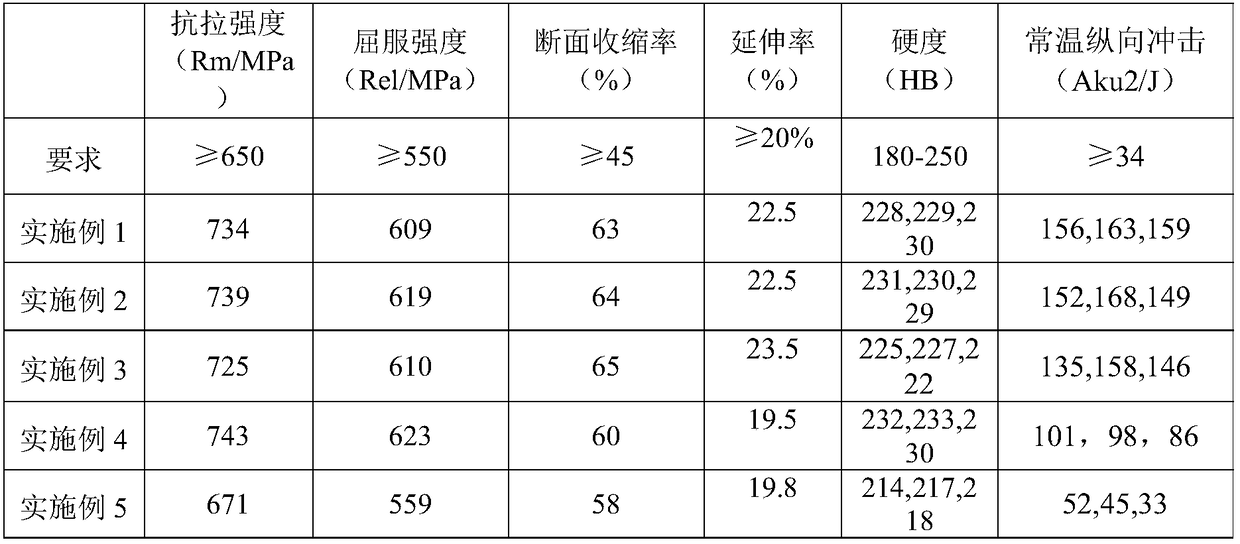

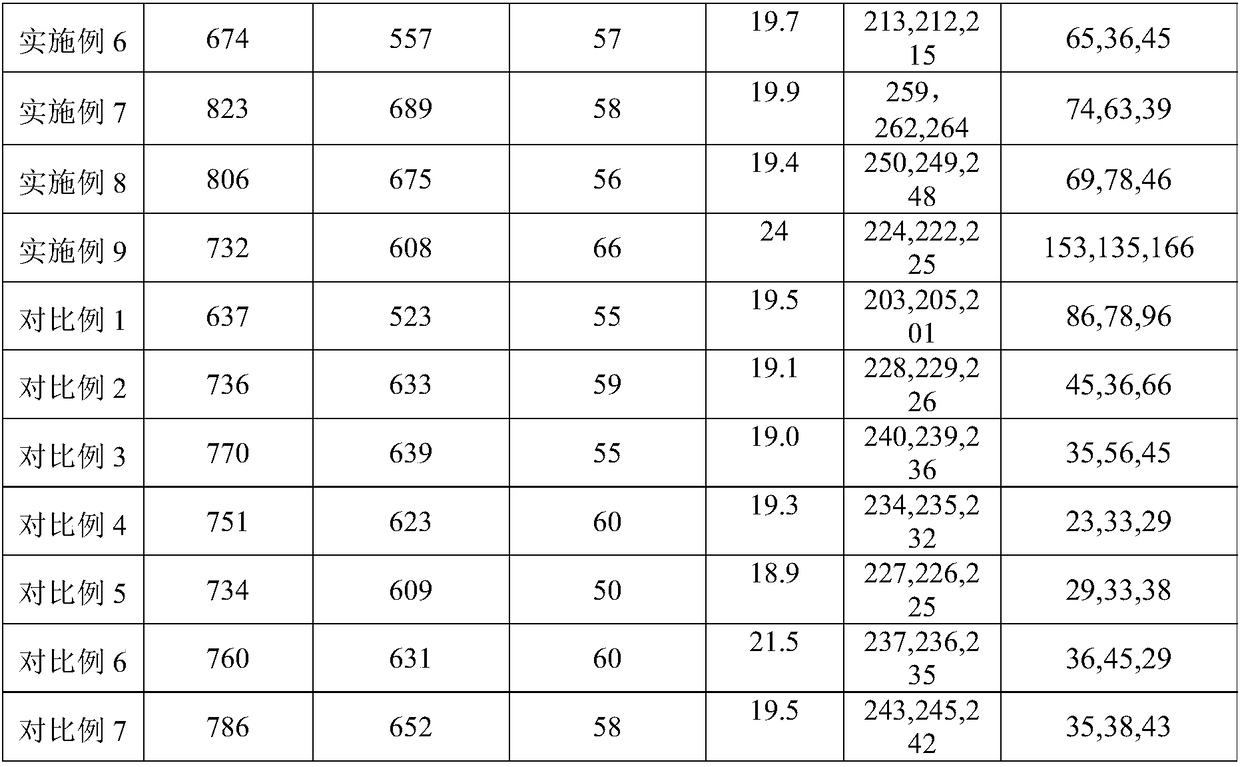

Examples

Embodiment 1

[0045] In terms of weight percentage, the raw materials of the steel pipe include 0.33% C, 0.50% Si, 1.30% Mn, 0.020% P, 0.015% S, 0.012% Ti and 0.0030% B, and the rest are Fe and not Avoid impurities. The C equivalent is 0.546%.

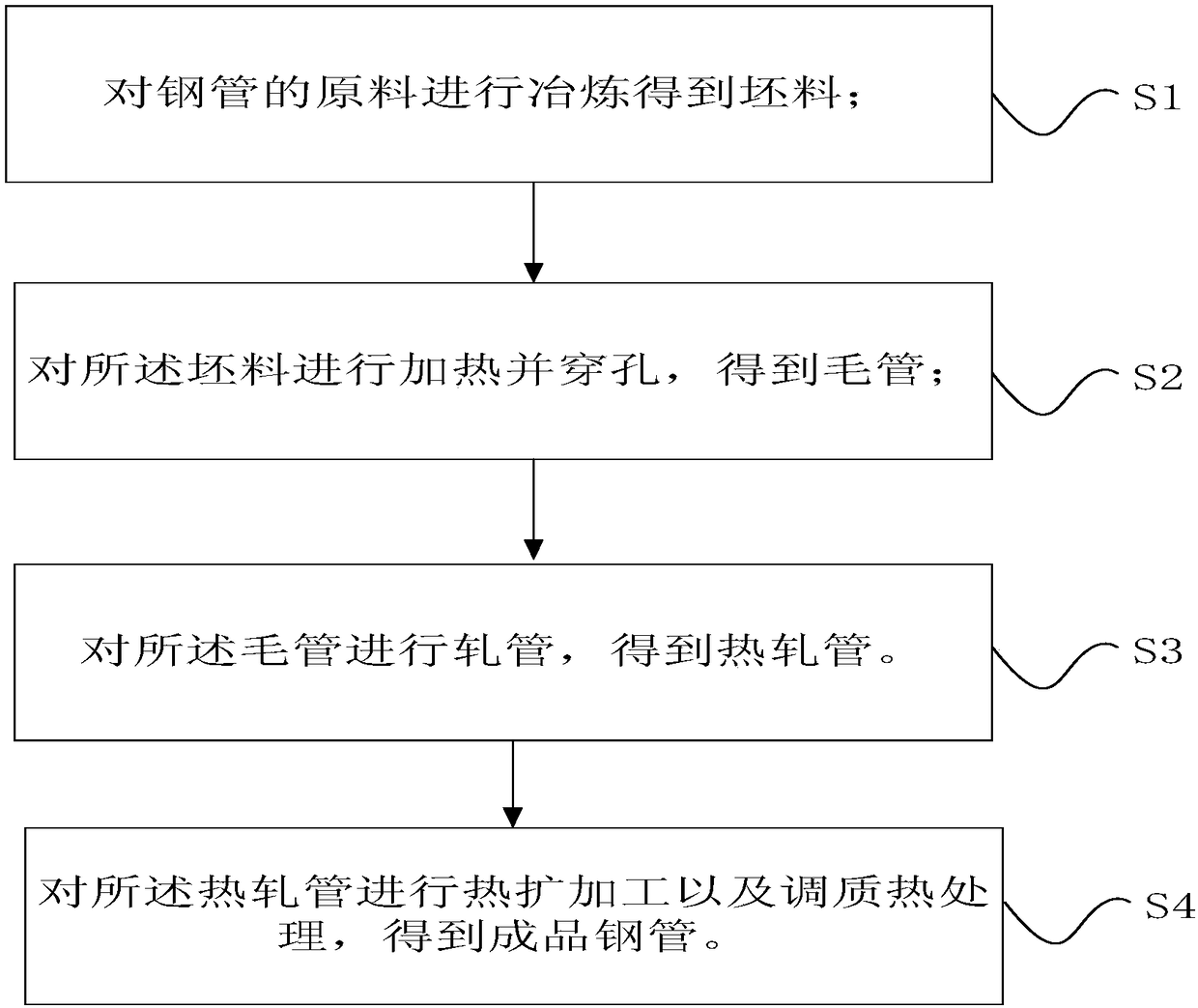

[0046] The specific steel pipe production process includes:

[0047] Step S1, smelting the raw material of the steel pipe to obtain a billet.

[0048] Specifically, raw materials are smelted in an electric furnace, refined outside the furnace, vacuum degassed and arc-shaped continuous casting to obtain billets.

[0049] Step S2, heating the above-mentioned blank, and then piercing with a tapered roller to obtain a capillary tube.

[0050] Specifically, firstly, the billet is heated, and the heating process includes a preheating stage, a heating stage I, a heating stage II, a heating stage III, a soaking stage I and a soaking stage II. The time of each stage is 10min, 15min, 25min, 20min, 20min and 10min respectively. Specifically, after heating...

Embodiment 2

[0059] The difference from Example 1 is that the raw material of the steel pipe includes 0.25% of C, 0.15% of Si, 1.70% of Mn, 0.01% of P, 0.011% of S, 0.04% of Ti and 0.0005% of b. The C equivalent is 0.59%. In addition, in the process of tempering and tempering the above-mentioned pre-tube to obtain the above-mentioned finished steel pipe, the heating temperature is 930° C., the holding time is 10 minutes, and the above-mentioned pre-tube after water cooling and quenching is tempered at 670° C. Air cooling after heat preservation for 40 minutes to obtain the above-mentioned finished steel pipe.

Embodiment 3

[0061] The difference from Example 1 is that the raw material of the steel pipe includes 0.29% C, 0.30% Si, 1.53% Mn, 0.014% P, 0.005% S, 0.024% Ti and 0.0016% B. The C equivalent is 0.596%. In addition, in the process of tempering and heat-treating the above-mentioned pre-tube to obtain the above-mentioned finished steel pipe, the heating temperature is 920°C, the holding time is 15min, and the above-mentioned pre-tube after water cooling and quenching is tempered at 640°C, After heat preservation for 60 minutes, it was air-cooled to obtain the above-mentioned finished steel pipe.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com