Graphene plasmonic gas sensor

A plasmon and graphene technology, applied in the field of infrared optical sensing, can solve problems such as detection of difficult gas samples

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

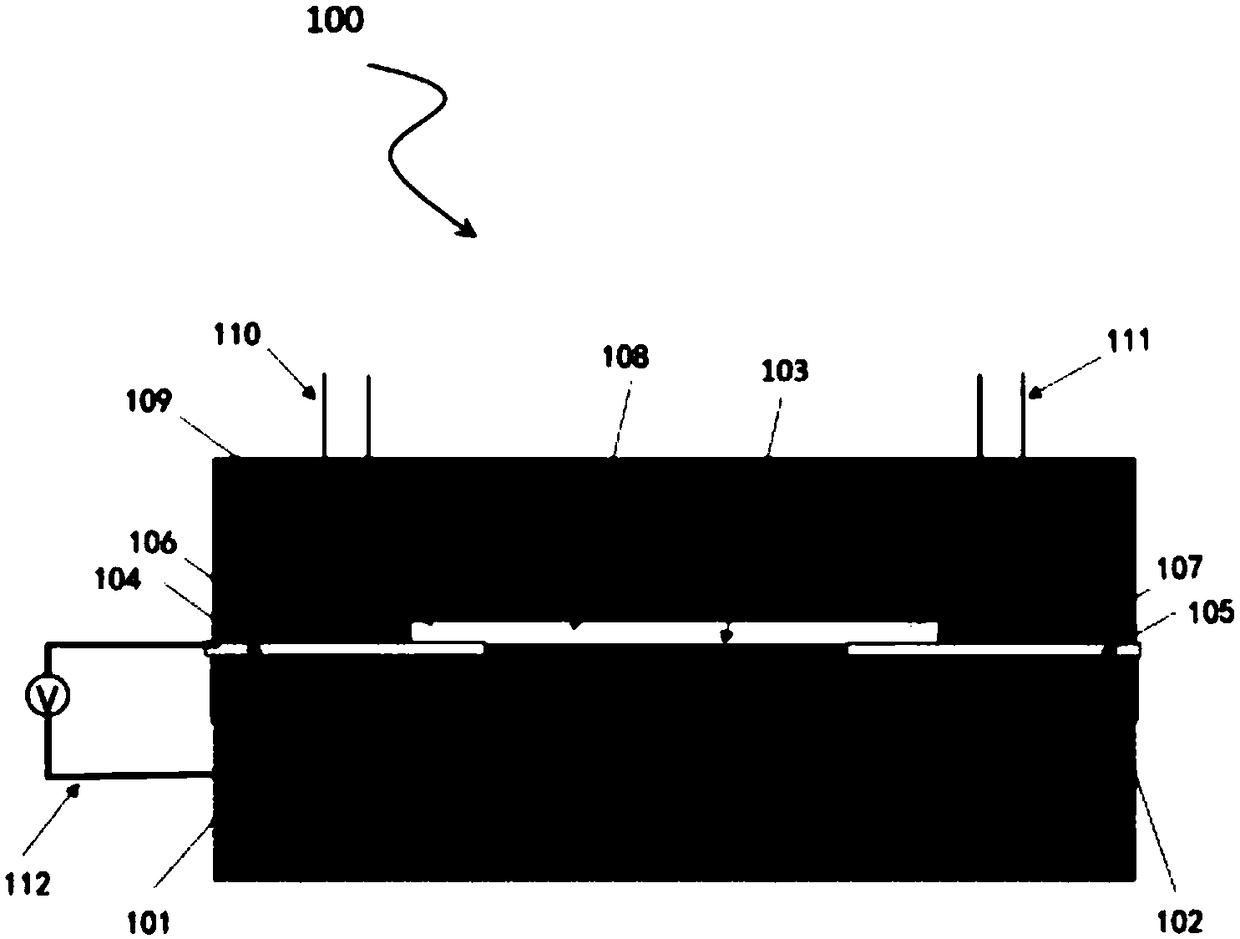

[0042] figure 1 Shown is a cross-sectional view of the graphene plasmonic gas sensor according to the first embodiment of the present invention. According to the first embodiment of the present invention, the graphene plasmonic gas sensor 100 in this embodiment includes sequentially from bottom to top Substrate 101, dielectric layer 102, graphene layer 103, microcavity 108, and cover plate 109,

[0043] Wherein the two ends of the graphene layer 103 are respectively provided with a metal electrode 104 and a metal electrode 105, wherein the metal electrode 104 and the metal electrode 105 are selected from chromium, titanium, iron, aluminum, copper, gold, silver, platinum.

[0044] The two ends of the microcavity 108 are respectively provided with a patterned coating 106 forming a microcavity channel and a patterned coating 107 forming a microcavity channel; the thickness of the microcavity 108 is in the range of 10-200 nm.

[0045] Wherein the cover plate 109 is respectively p...

Embodiment 2

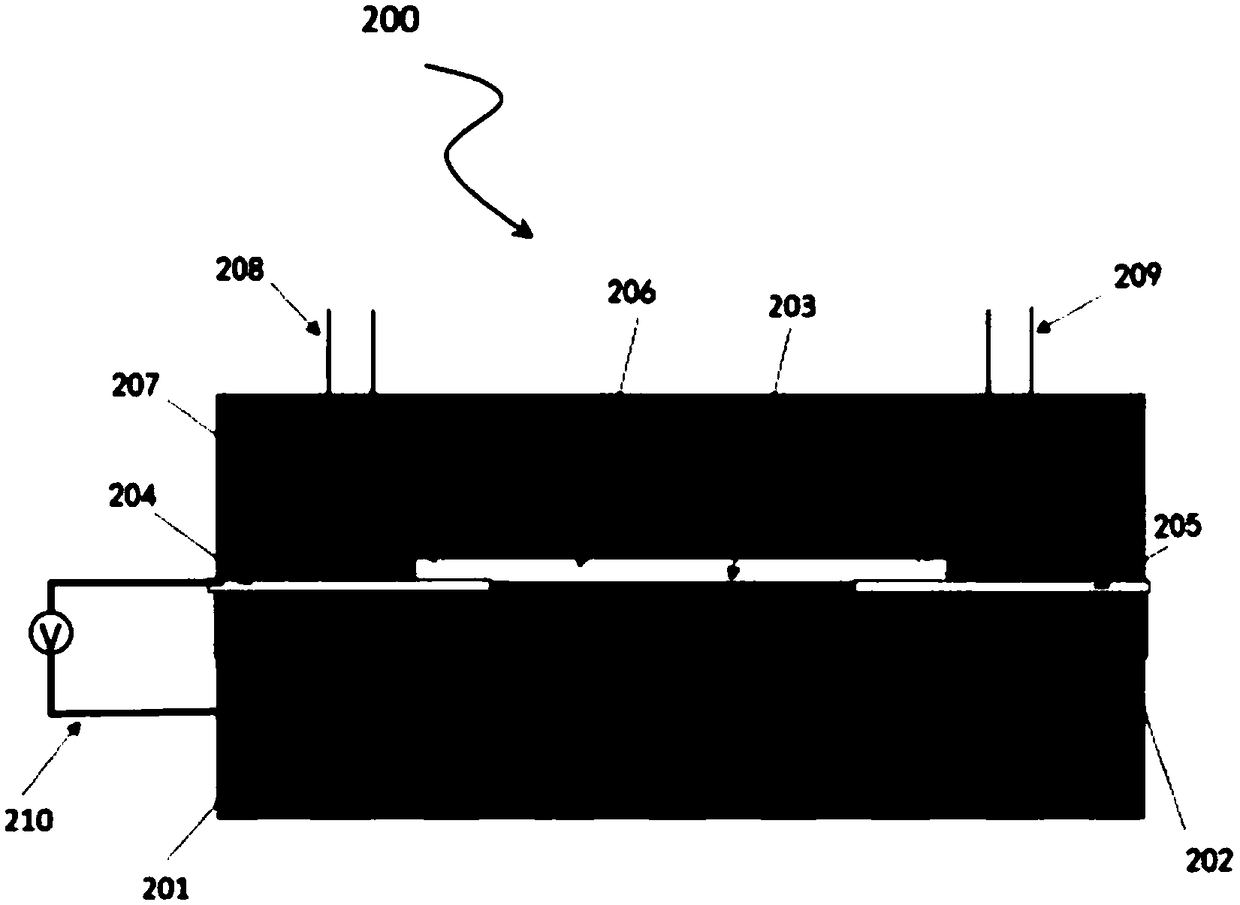

[0061] figure 2 A schematic structural diagram (sectional view) of the graphene plasmonic gas sensor according to the second embodiment of the present invention is shown.

[0062] Wherein the graphene plasmonic gas sensor 200 in this embodiment includes a substrate 201, a dielectric layer 202, a graphene layer 203, a microcavity 206, and a cover plate 207 in sequence from bottom to top,

[0063] Wherein the two ends of the graphene layer 203 are respectively provided with a metal electrode 204 and a metal electrode 205;

[0064] Wherein the cover plate 207 is respectively provided with a sample inlet channel 208 and a sample outlet channel 209 communicated with the microcavity 206;

[0065] The substrate 201 is connected to the metal electrode 204 or the metal electrode 205 through a gate voltage source 210 .

Embodiment 3

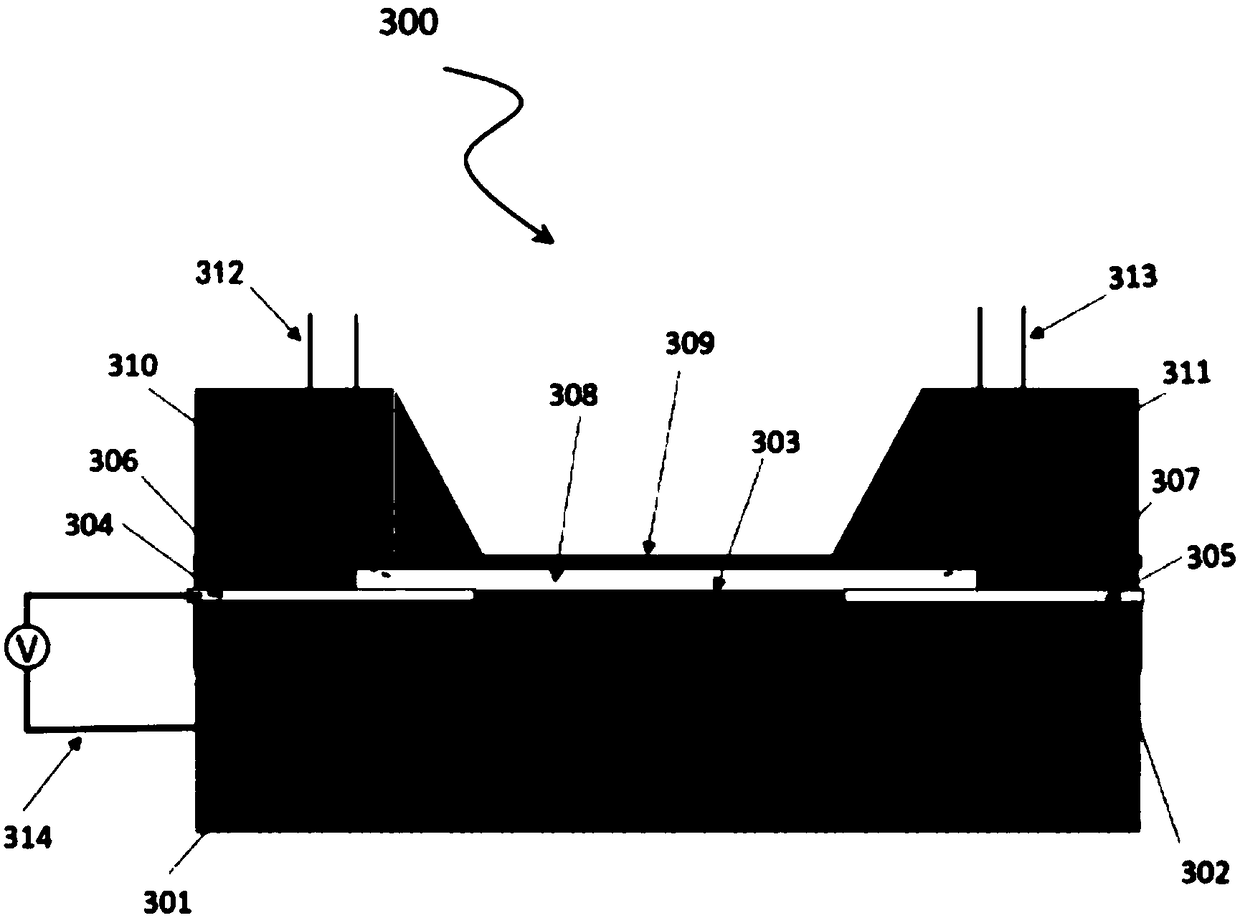

[0067] image 3 A schematic structural diagram (sectional view) of the graphene plasmonic gas sensor according to the third embodiment of the present invention is shown.

[0068] Wherein the graphene plasmonic gas sensor 300 in this embodiment includes a substrate 3201, a dielectric layer 302, a graphene layer 303, an infrared window 309, a microcavity 308, and a cover plate 310 and a cover plate 311 from bottom to top,

[0069] Wherein the two ends of the graphene layer 303 are respectively provided with a metal electrode 304 and a metal electrode 305;

[0070] Wherein the sample inlet channel 312 and the sample outlet channel 313 communicated with the microcavity 308 are respectively set on the cover plate 310 and the cover plate 311;

[0071] Wherein the substrate 301 is connected to the metal electrode 304 or the metal electrode 305 through a gate voltage source 314;

[0072] Wherein the infrared window 309 includes a SiN window, which can transmit infrared light.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com