A Soft Membrane Ultrasonic Phased Array Probe for Testing T-shaped Welds of Corrugated Steel Webs

A corrugated steel web, ultrasonic phased array technology, applied in the field of phased array probes, can solve the problems of detection quantitative error, large sensitivity difference, inability to overcome the flat surface coupling compensation problem, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

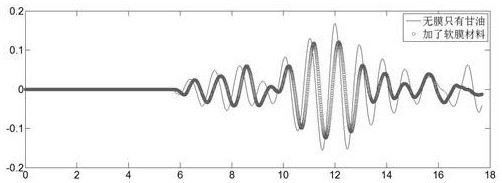

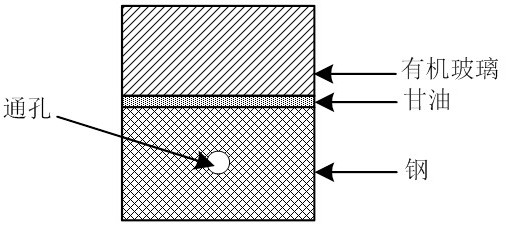

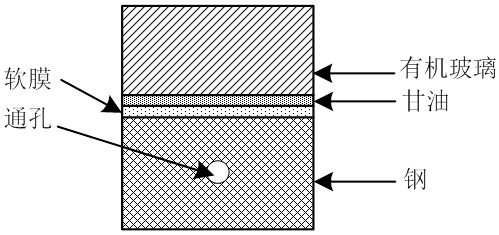

[0017] Firstly, wave2000 is used for simulation research, and a simulation model of a phased array probe without soft membrane is established, such as figure 1 As shown, the piezoelectric wafer is excited from the middle of the top, and the whole probe model is made of plexiglass material (sound velocity of 2759 m / s), glycerin (sound velocity of 1900 m / s), ordinary steel material (sound velocity of 5659 m / s) from top to bottom. m / s) and a through hole (representing a φ5 hole with a sound velocity of 340 m / s). Ultrasonic waves are excited through the piezoelectric wafers and propagate in the structure, and the ultrasonic signals are received at the bottom below the holes. Then establish the soft membrane phased array probe simulation model, such as figure 2 As shown, the piezoelectric wafer is excited from the middle of the top, and the whole probe model from top to bottom is plexiglass material (sound velocity of 2759 m / s), glycerin (sound velocity of 1900 m / s), soft film ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com