Method of manufacturing micro convex lens by using PDMS

A micro-convex lens, SU-8 technology, applied in the photoplate process of lens, pattern surface, optics, etc., can solve the problems of difficult control of geometric size, easy deformation of sphere, difficult mass production of glass bead lenses, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

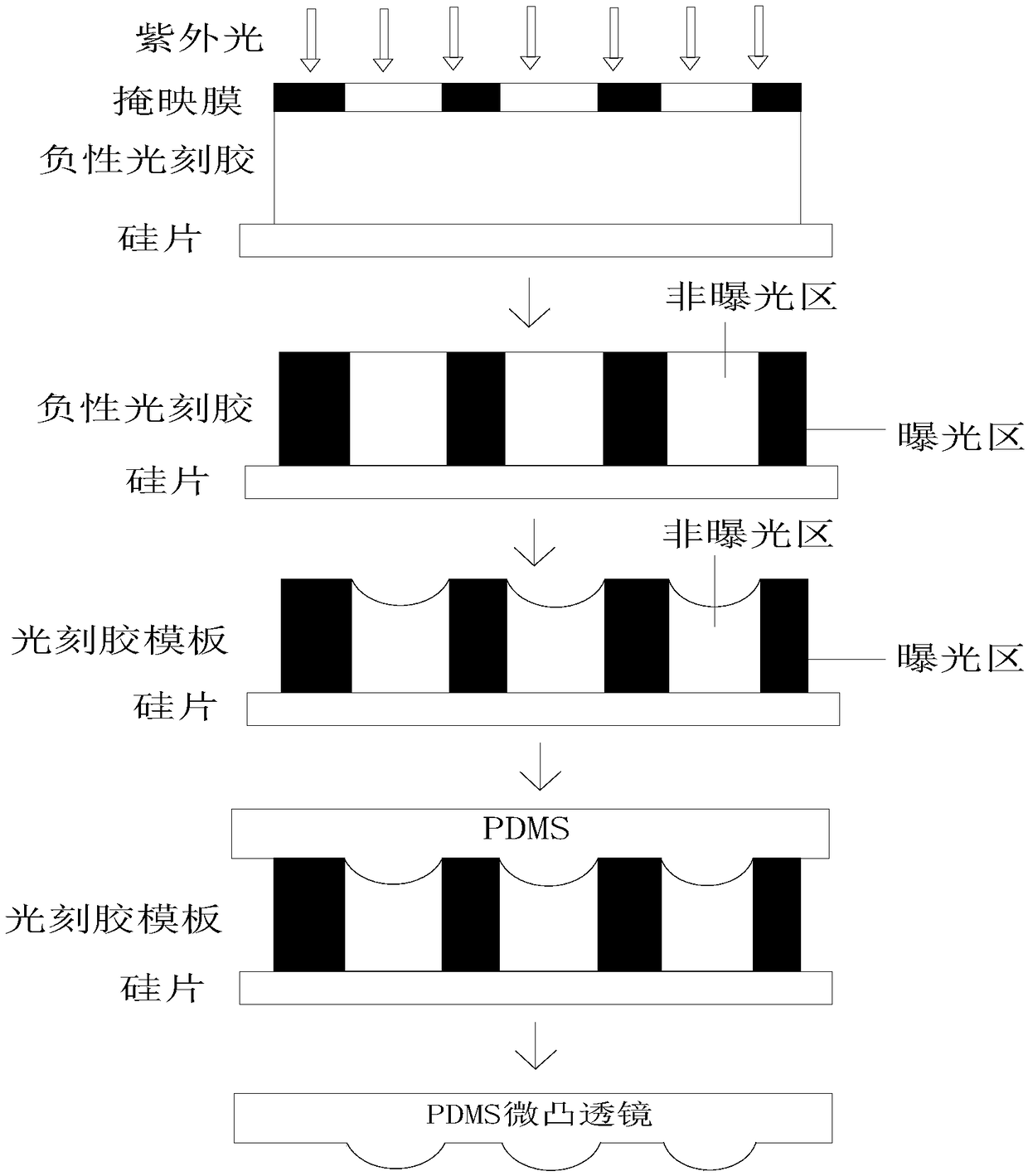

[0043] A method of utilizing PDMS to make a 100-fold magnification micro-convex lens, comprising the following steps:

[0044] Step (1): Clean and dry the silicon wafer, that is, first use the RCA cleaning process to clean the silicon wafer, and then place the silicon wafer on a high-temperature heating plate to thoroughly dry the moisture on the surface of the silicon wafer;

[0045] Step (2): Coating, that is, coating a layer of negative photoresist with a uniform thickness on the top surface of the silicon wafer by using the spin coating method, and the negative photoresist is SU-8 negative photoresist 2025 series, the spin coating method refers to uniformly coating negative photoresist on the top surface of the silicon wafer by a spin coater, while preventing bubbles from appearing in the photoresist, and using the self-leveling effect of the photoresist to statically Set aside for 40 minutes to remove the ripples generated by spin coating; when coating, the spin coating m...

Embodiment 2

[0059] A kind of method that utilizes PDMS to make micro-convex lens with magnification 200 times, comprises the following steps:

[0060] Step (1): Clean and dry the silicon wafer, that is, first use the RCA cleaning process to clean the silicon wafer, and then place the silicon wafer on a high-temperature heating plate to thoroughly dry the moisture on the surface of the silicon wafer;

[0061] Step (2): Coating, that is, coating a layer of negative photoresist with a uniform thickness on the top surface of the silicon wafer by using the spin coating method, and the negative photoresist is SU-8 negative photoresist 2150 series, the spin coating method refers to uniformly coating negative photoresist on the top surface of the silicon wafer by a spin coater, while preventing bubbles from appearing in the photoresist, and using the self-leveling effect of the photoresist to statically Set aside for 50 minutes to remove the ripples produced by spin coating; when coating, the spi...

Embodiment 3

[0075] A kind of method utilizing PDMS to make 300 times magnification micro-convex lens, comprises the following steps:

[0076] Step (1): Clean and dry the silicon wafer, that is, first use the RCA cleaning process to clean the silicon wafer, and then place the silicon wafer on a high-temperature heating plate to thoroughly dry the moisture on the surface of the silicon wafer;

[0077] Step (2): Coating, that is, coating a layer of negative photoresist with a uniform thickness on the top surface of the silicon wafer by using the spin coating method, and the negative photoresist is SU-8 negative photoresist 3035 series, the spin coating method refers to uniformly coating negative photoresist on the top surface of the silicon wafer by a spin coater, while preventing bubbles from appearing in the photoresist, and using the self-leveling effect of the photoresist to statically The ripples produced by spin coating can be removed after 45 minutes; when coating, the spin coating ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com