Volume minimization-based design method and device of warped heat exchanger

A design method and heat exchanger technology, applied in the direction of instruments, calculations, special data processing applications, etc., can solve the problem that the heat exchanger cannot meet the volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

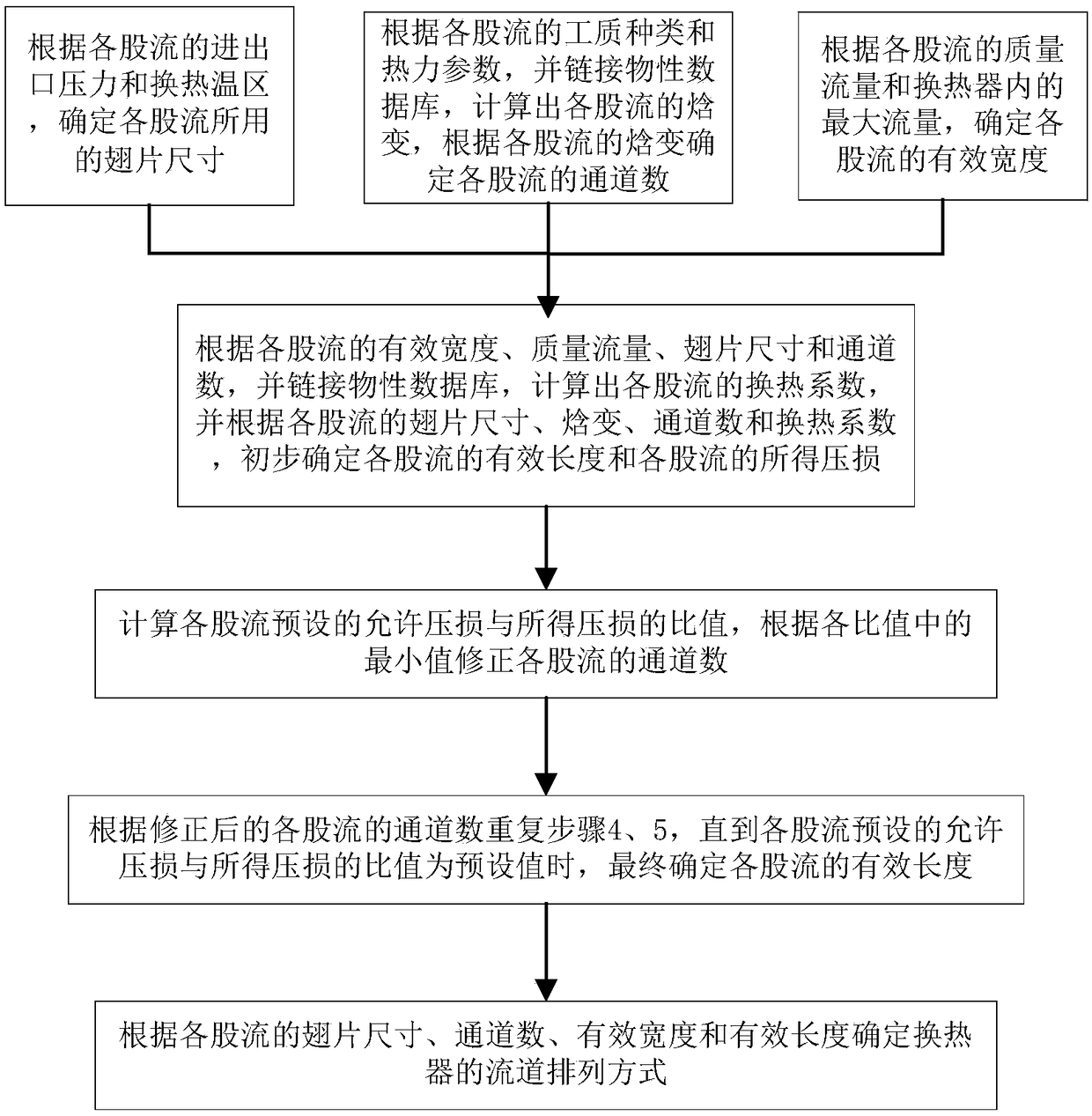

[0076] According to an embodiment of the present invention, a design method for tilted heat exchangers based on volume minimization is provided, see figure 2 ,include:

[0077] Step 1. Determine the fin size used for each stream according to the inlet and outlet pressures and heat transfer temperature zones of each stream;

[0078] Step 2. Calculate the enthalpy change of each stream according to the working fluid type and thermal parameters of each stream, and link to the physical property database, and determine the number of channels of each stream according to the enthalpy change of each stream;

[0079] Step 3. Determine the effective width of each stream according to the mass flow rate of each stream and the maximum flow rate in the heat exchanger;

[0080] Step 4. Calculate the heat transfer coefficient of each stream according to the effective width, mass flow rate, fin size and channel number of each stream, and link the physical property database, and calculate the...

Embodiment 2

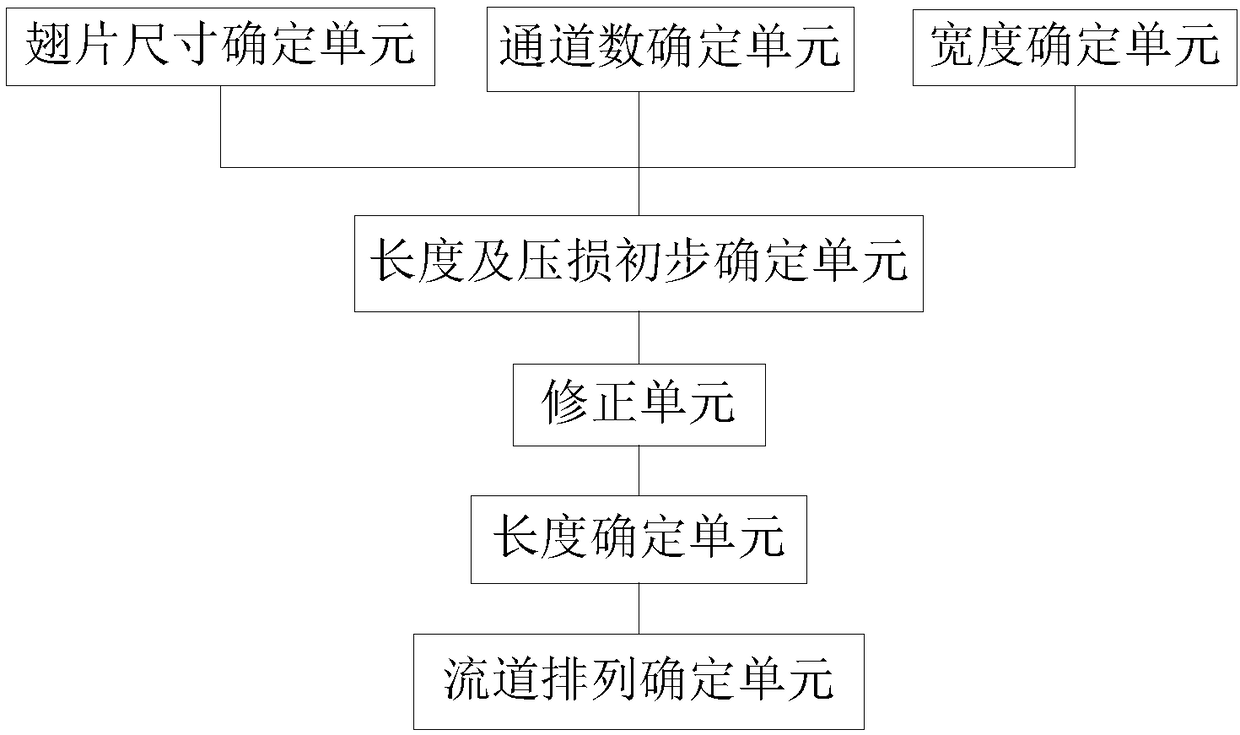

[0107] According to another aspect of the embodiment of the present invention, a device for designing a tilted heat exchanger based on volume minimization is provided, see image 3 ,include:

[0108] The fin size determination unit is used to determine the fin size used for each stream according to the inlet and outlet pressures and heat exchange temperature zones of each stream;

[0109] The channel number determination unit is used to calculate the enthalpy change of each stream according to the working medium type and thermal parameters of each stream and link to the physical property database, and determine the channel number of each stream according to the enthalpy change of each stream;

[0110] A width determination unit is used to determine the effective width of each stream according to the mass flow rate of each stream and the maximum flow rate in the heat exchanger;

[0111] The length and pressure loss preliminary determination unit is used to calculate the heat t...

Embodiment 3

[0133] The design parameters are

[0134] Stream

Fluid

qm(g / s)

Tin(K)

pin(bar)

Tout(K)

Pout(bar)

A

22.4

14.2

9.96

<10

>9.95

B

40

9.79

1.18

>12.80

>1.16

[0135] Initially designed fin size (mm)

[0136]

[0137] The runner arrangement is: (BA / 12)B, the effective width is 270mm, the effective length is 620mm, and the effective volume is about 20.82L.

[0138] The export parameters obtained by the commercial plate-fin heat exchanger design software Aspen Plate-Fin are:

[0139]

[0140] Because there is an error of about 20% in the heat transfer j and f factor fitting formulas, there should be a margin of about 20% in the pressure loss and effective length; the pressure loss at the low-pressure end is 755.7Pa, and the magnification of 20% is 755.7*1.2= 906.84Pa<2000Pa=0.02bar meets the requirements; the effective length is 620mm, and the effective length must be 620 / 1.2=...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com