Printable flexible conductive paste and preparation method thereof

A flexible conductive and slurry technology, applied in the direction of conductive materials dispersed in non-conductive inorganic materials, cable/conductor manufacturing, circuits, etc., can solve the problems of low mechanical deformation capacity, poor stability, complex composition, etc., and achieve mechanical deformation The effect of strong power, high stability and simple ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings.

[0018] Step 1. Weighing: 10g of fluororubber, 18g of flaky silver powder, 40g of butyl acetate, and 10g of fluorocarbon surfactant.

[0019] Step 2. Stir the fluororubber, butyl acetate, and fluorocarbon surfactant in proportion for 1 hour to make them evenly mixed.

[0020] After step 3 and step 2 are mixed evenly, 18g of flake silver powder is added therein, stirred and mixed evenly, and a printable flexible conductive paste is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

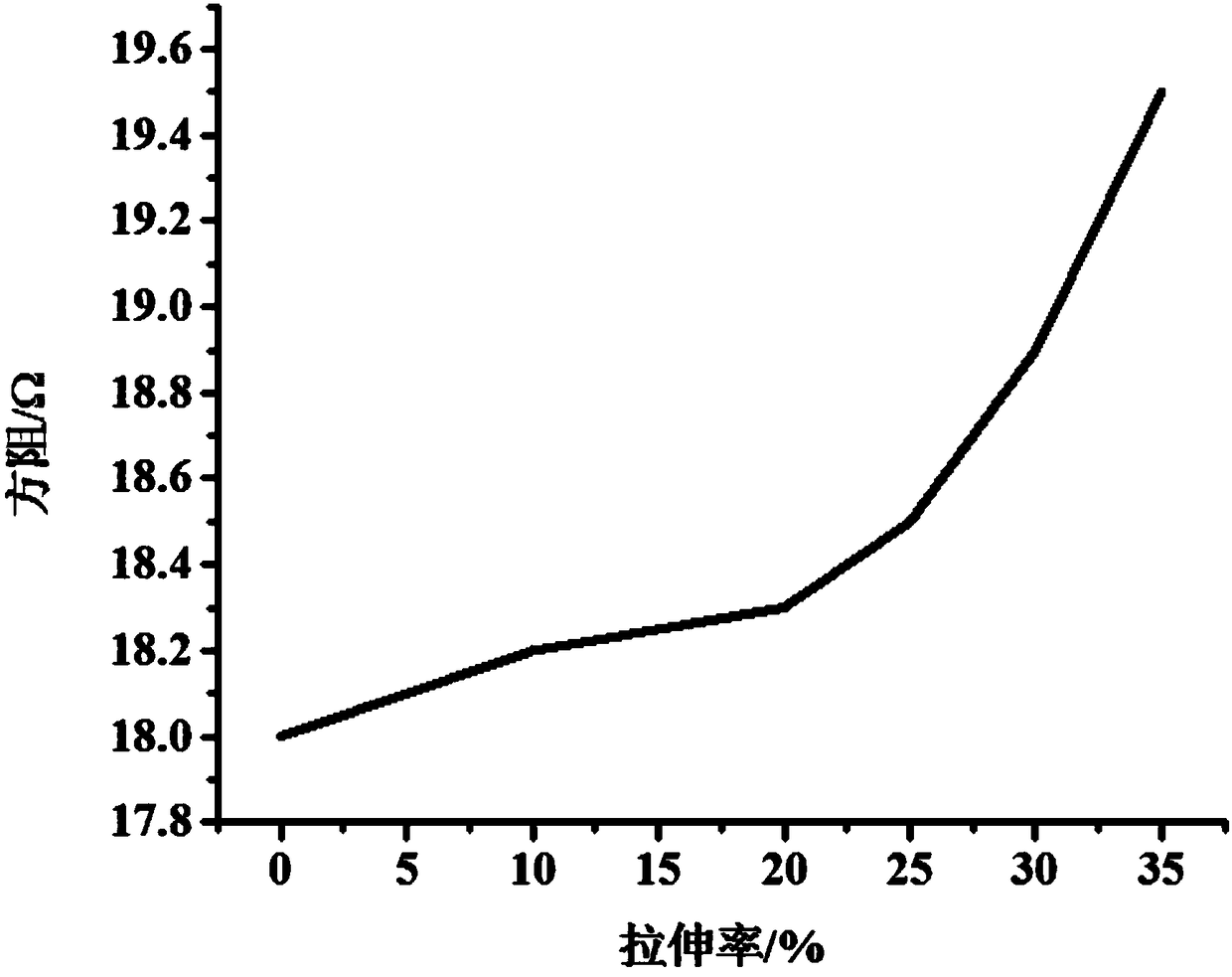

| electrical resistance | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com