Single-sided paint spraying room

A technology for painting booths and painting equipment, applied in painting booths, spraying devices, etc., can solve the problems of filter shutdown and other problems, and achieve the effects of reducing labor costs, simple production, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

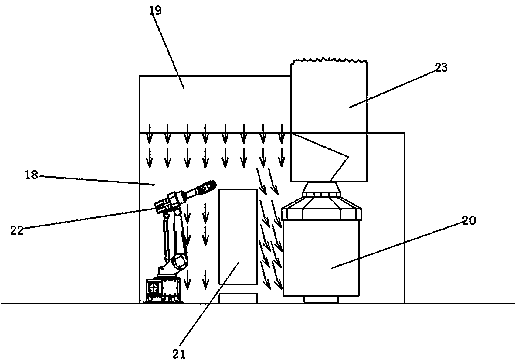

[0048] Such as figure 1 , a kind of one-sided spray booth, comprising a spray booth main body 18, a static pressure chamber 19 connected with the spray booth main body 18 and an exhaust chamber 23, a workpiece 21 is arranged in the paint spray booth main body 18, and a spray paint is arranged on one side of the workpiece 21 Equipment 22 , the other side of the workpiece 21 is provided with a rotary filter device 20 , and the rotary filter device 20 is connected to an exhaust chamber 23 .

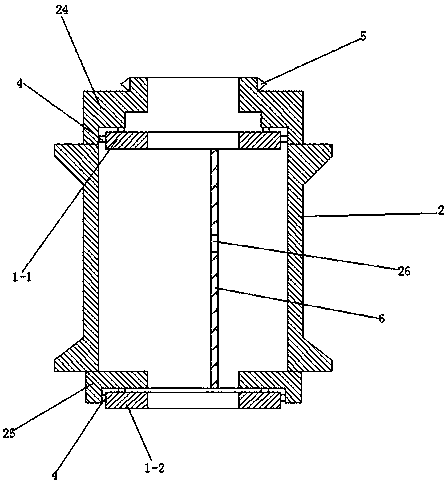

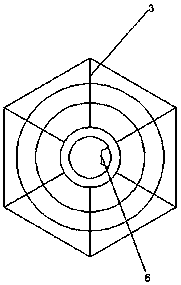

[0049] Such as figure 2 , as shown in 3, the rotary filter device 20 includes a first circular ring 1-1, a second circular ring 1-2 and a filter box set on the outside of the first circular ring 1-1 and the second circular ring 1-2. In the adult 2, the first ring 1-1 and the second ring 1-2 are arranged side by side up and down, and the first ring 1-1 and the second ring 1-2 are respectively symmetrically provided with rollers 4, There are four rollers 4 on the first ring 1-1 and the seco...

Embodiment 2

[0057] Such as Figure 8 As shown, the difference from Embodiment 1 is that the rotary filter device 20 is located outside the main body 18 of the spray booth, and the rotary filter device 20 is connected to the exhaust chamber 23 .

Embodiment 3

[0059] Such as Figure 9 As shown, the difference from Embodiment 1 is that eight interlayers 27 are arranged between every two support rods 3 in the rotary filter device 20 , and the entire filter box assembly 2 is divided into 48 areas for respectively placing filter boxes. The filter boxes are independent of each other. When the filter box needs to be replaced, the filter box is rotated to the position where the baffle plate 6 is located, and the filter box is taken out manually.

[0060] The working principle of the rotary filter device 20: the motor drives the gear ring 5 to rotate through the tooth chain, the filter box assembly 2 rotates under the action of the gear ring 5, and the air containing paint particles enters the box body 8 from the air inlet 14 through the exhaust. Inside, through the gap between the upper support frame 11 and the lower support frame 12, it enters the serpentine filter channel formed by the filter paper 10, wherein the paint particles are tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com