Restoration method for northern industrial and mining wasteland heavy metal pollution

A remediation method and wasteland technology, applied in the field of soil pollution remediation, can solve problems such as insufficient stabilizer dosage, difficulty in survival of soil microorganisms and plants, and influence on soil physical and chemical properties, and achieve the effect of promoting rapid and healthy growth and rich matrix nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

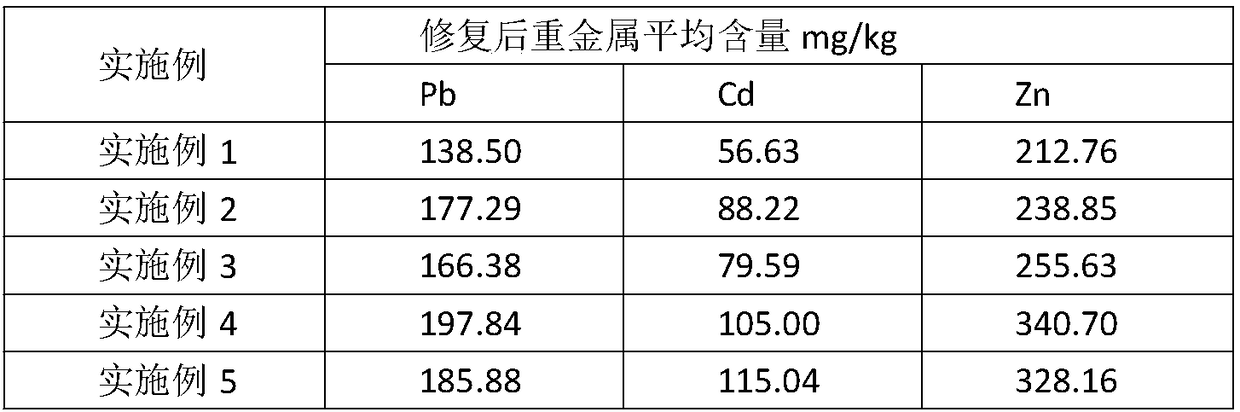

Embodiment 1

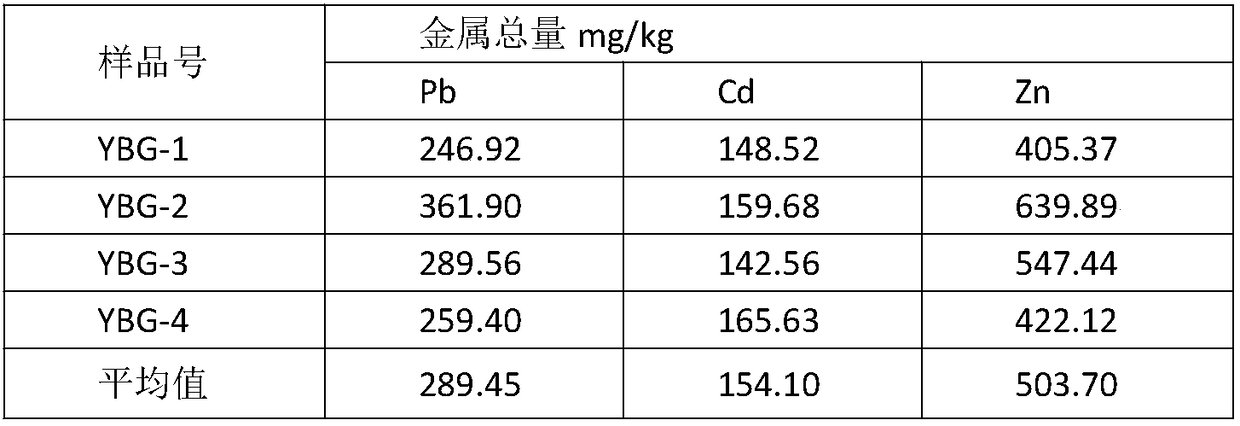

[0027] A restoration method for heavy metal pollution in northern industrial and mining wasteland, comprising the following steps:

[0028] Clean up the area to be repaired, remove sundries, weeds, garbage, etc., level the raised parts of the ground, ensure that the slope is below 25°, excavate the contaminated soil, the excavation depth is 40cm, and lay a layer on the bottom of the foundation pit HDPE anti-seepage membrane, the excavated soil is uniformly mixed with the stabilizer and backfilled, and a nutrient matrix layer containing seeds is sprayed on the backfilled soil, and the thickness of the nutrient matrix layer is 6cm.

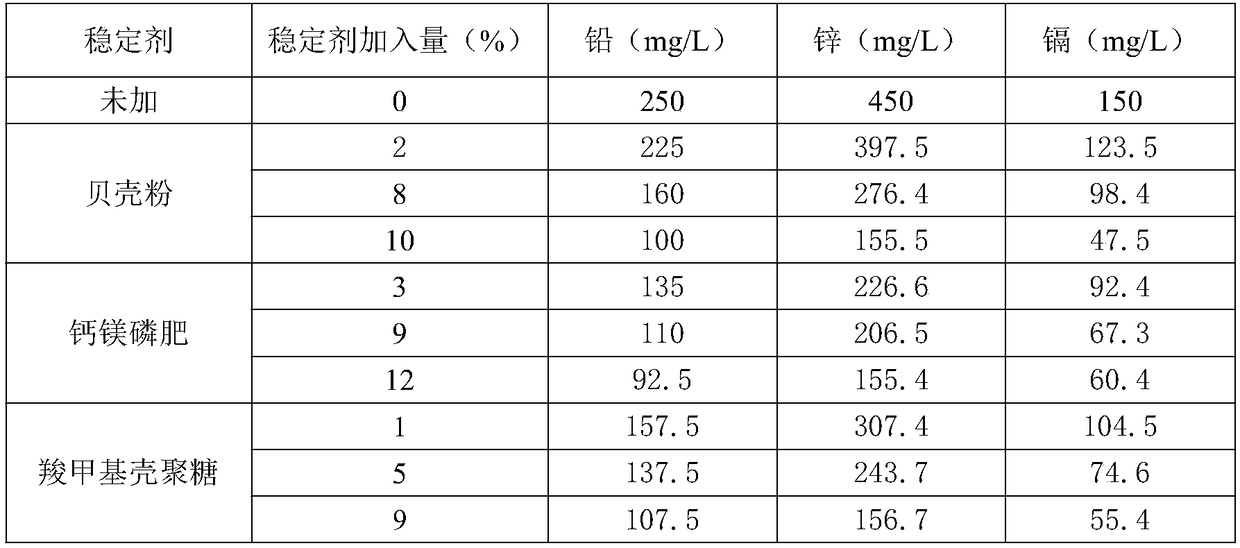

[0029] The stabilizer comprises the following components and their weight distribution ratio with dry soil: 10% of shell powder, 12% of calcium magnesium phosphate fertilizer and 9% of carboxymethyl chitosan. The dry soil is the excavated heavy metal soil dry soil.

[0030] The nutrient matrix layer includes the following components and volume rati...

Embodiment 2

[0032]A restoration method for heavy metal pollution in northern industrial and mining wasteland, comprising the following steps:

[0033] Clean up the area to be repaired, remove sundries, weeds, garbage, etc., level the raised parts of the ground to ensure that the slope is below 25°, excavate the polluted soil, the excavation depth is 35cm, and lay a Layer HDPE anti-seepage film, backfill the excavated soil evenly mixed with stabilizer, spray a layer of nutrient matrix layer containing seeds on the backfilled soil, the thickness of the nutrient matrix layer is 7cm.

[0034] The stabilizer comprises the following components and their weight distribution ratio with dry soil: 2% of shell powder, 3% of calcium magnesium phosphate fertilizer, 1% of carboxymethyl chitosan, and the dry soil is excavated heavy metal soil.

[0035] The nutrient matrix layer includes the following components and volume ratios: 10% clay, 18% perlite, 10% plant fiber, 13.62% montmorillonite, 5% control...

Embodiment 3

[0037] A restoration method for heavy metal pollution in northern industrial and mining wasteland, comprising the following steps:

[0038] Clean up the area to be repaired, remove sundries, weeds, garbage, etc., level the raised parts of the ground, ensure that the slope is below 25°, excavate the polluted soil, the excavation depth is 38cm, and lay a layer on the bottom of the foundation pit HDPE anti-seepage membrane, the excavated soil is evenly mixed with the stabilizer and backfilled, and a nutrient matrix layer containing seeds is sprayed on the backfilled soil, and the thickness of the nutrient matrix layer is 4cm.

[0039] The stabilizer includes the following components and their weight distribution ratio with dry soil: 6% of shell powder, 7% of calcium magnesium phosphate fertilizer, 5% of carboxymethyl chitosan, and the dry soil is excavated heavy metal soil dry soil.

[0040] The nutrient matrix layer includes the following components and volume ratios: 24% clay, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com