Olefin polymerization catalyst and preparation method thereof

A technology for olefin polymerization and catalyst, applied in the field of catalyst and its preparation, can solve the problem of high price and achieve the effect of high bulk density and good shape of polymer particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The invention provides a method for preparing an olefin polymerization catalyst. In the present invention, the phosphate-based clay is used as a support for the olefin polymerization catalyst, and the transition metal compound can be supported by treatment with aluminum alkyl.

[0028] The present invention provides a specific preparation step of an olefin polymerization catalyst including:

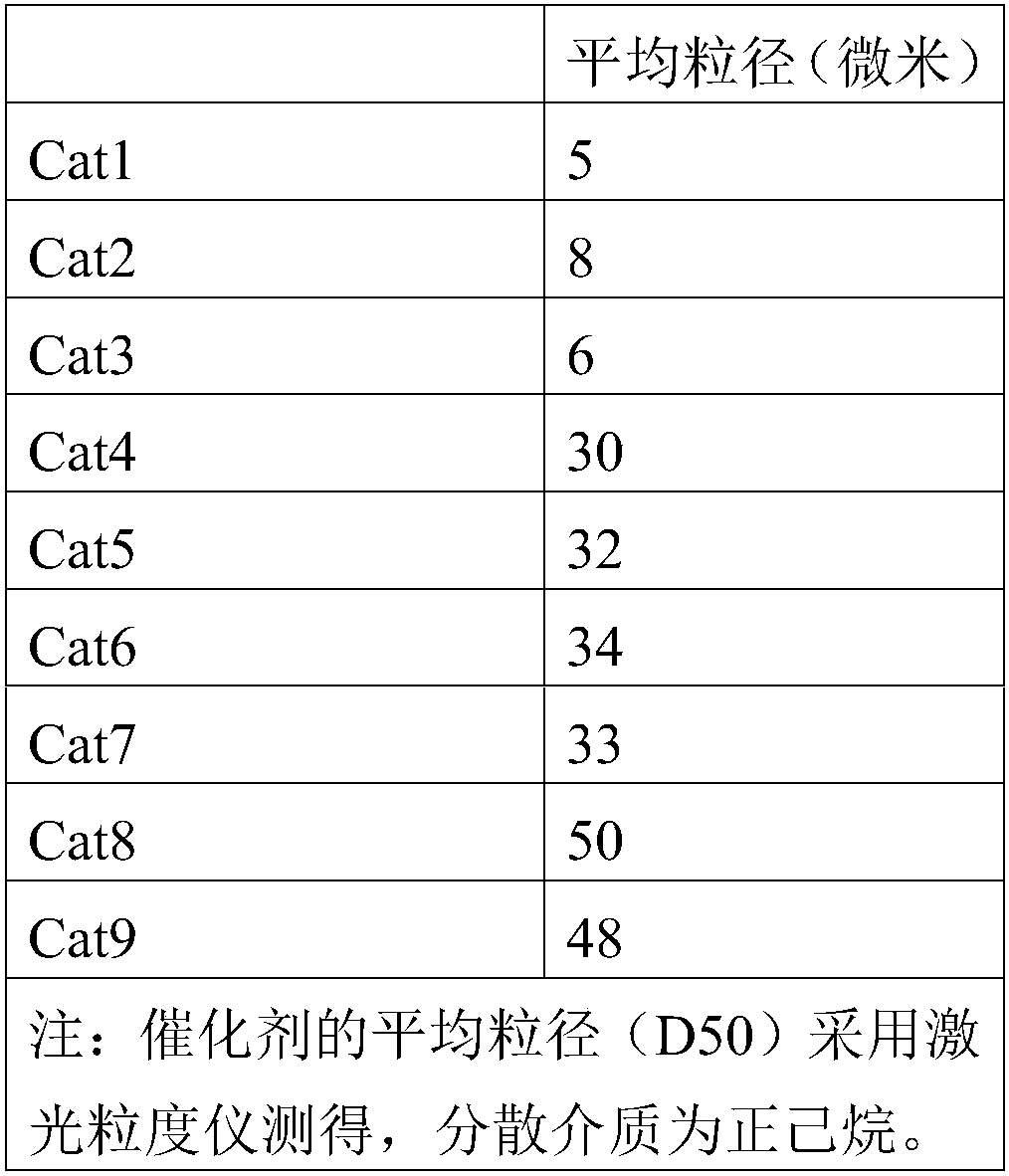

[0029] 1) Phosphate clay (titanium hydrogen phosphate or zirconium hydrogen phosphate) is pre-ground, sieved or spray-dried with water to prepare particles with an average particle size of 5-50 microns;

[0030] 2) Disperse phosphate clay in toluene solution under the protection of inert gas (nitrogen or argon);

[0031] 3) Under inert gas protection and stirring, add alkyl aluminum (trimethyl aluminum, triethyl aluminum, tri-n-butyl aluminum or tri-isobutyl aluminum) to the mixed system obtained in step 2 for treatment (the added alkane The molar ratio of aluminum base to phosphate clay ...

Embodiment 1

[0039] Under the protection of nitrogen, accurately weigh 5g of titanium hydrogen phosphate (average particle size of 8 microns) and transfer it to a glass reactor fully replaced by nitrogen, and add 25ml of purified toluene with dewatering. After stirring for uniform dispersion, 20 ml of trimethylaluminum solution (2M toluene solution) was added, and stirred at 30°C for 1 hour.

[0040] Accurately weigh 50 mg of bis(butylcyclopentadienyl) zirconium dichloride under the protection of nitrogen and transfer it to a glass reactor that has been fully replaced by nitrogen, and add 15 ml of toluene purified by dewatering. Stir at 30°C to dissolve. 1ml of methylaluminoxane solution (10wt% toluene solution) was added, and stirring was continued for 0.5 hours.

[0041] The above two reaction systems were mixed under the protection of nitrogen and stirred at 40°C for 2 hours. After the reaction, let it stand still, filter the liquid after layering, wash twice with 30ml dewatered and refine...

Embodiment 2

[0044] Under the protection of nitrogen, accurately weigh 5g of titanium hydrogen phosphate (average particle size of 8 microns) and transfer it to a glass reactor fully replaced by nitrogen, and add 25ml of purified toluene with dewatering. After stirring to make the dispersion uniform, 25 ml of trimethylaluminum solution (2M toluene solution) was added and stirred at 30°C for 1 hour.

[0045] Accurately weigh 100 mg of rac-dimethyl bis(2-methyl-4,5-benzoindenyl)silyl zirconium dichloride under the protection of nitrogen and transfer it to a glass reactor that has been fully replaced by nitrogen. 15ml of toluene refined with water. Stir at 30°C to dissolve. 1ml of methylaluminoxane solution (10wt% toluene solution) was added, and stirring was continued for 0.5 hours.

[0046] The above two reaction systems were mixed under the protection of nitrogen and stirred at 40°C for 2 hours. After the reaction, let it stand still, filter the liquid after layering, wash twice with 30ml de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com