Wind power gear box heat exchanging mechanism and wind generating set with same

A technology of wind power gearbox and heat exchange mechanism, which is applied in wind turbines, wind power generation, machines/engines, etc., and can solve problems such as decreased heat dissipation capacity of heat exchangers, insufficient heat dissipation capacity of heat exchangers, high temperature shutdown failures of gearboxes, etc. Achieve the effect of improving reliability, reducing gearbox failure rate and avoiding bearing failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The invention improves the existing air-cooled heat exchange system, and achieves the purpose of improving the heat dissipation capacity of the heat exchange system by changing the fluid circuit structure of the existing air-cooled heat exchange system. The specific implementation method is as follows.

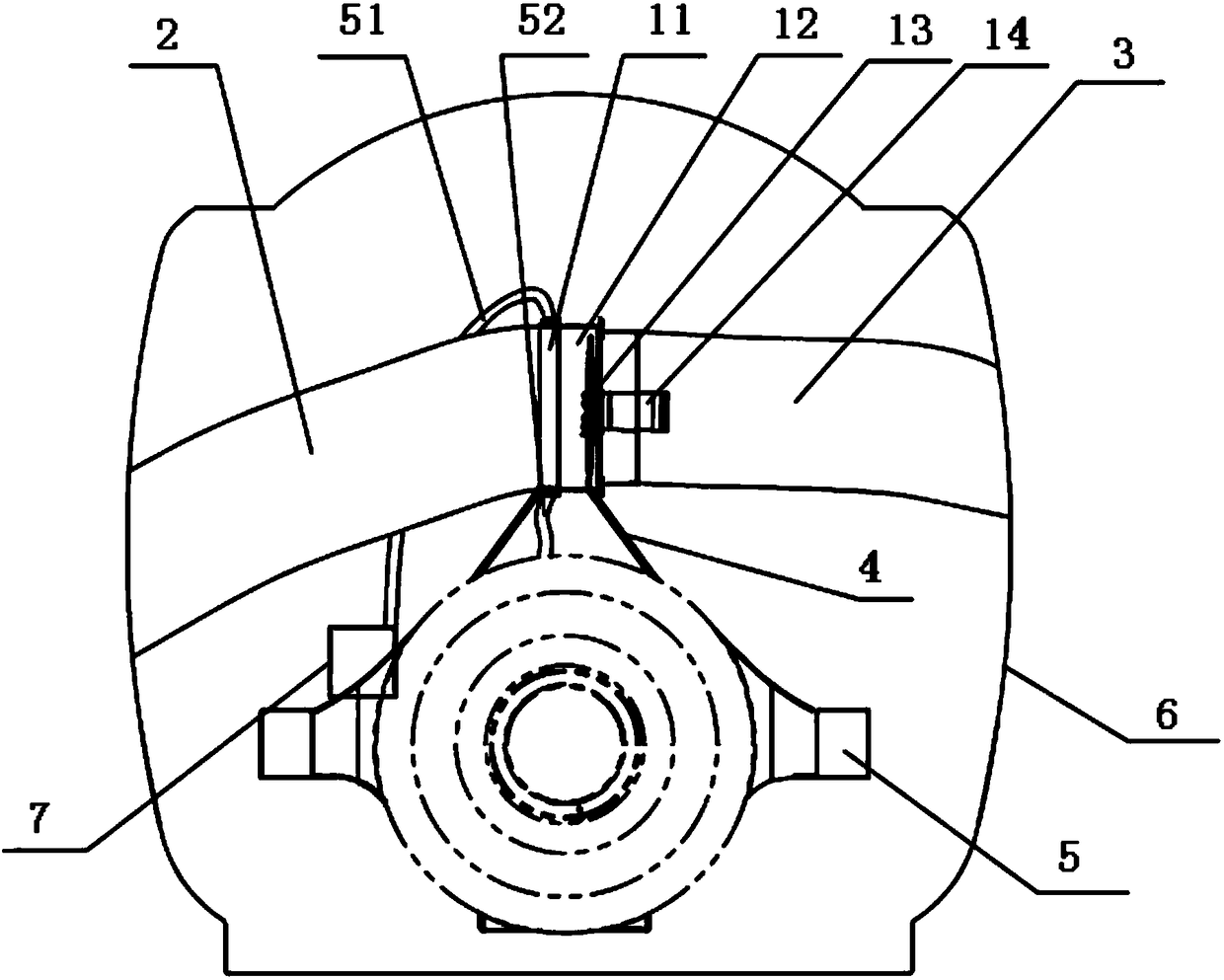

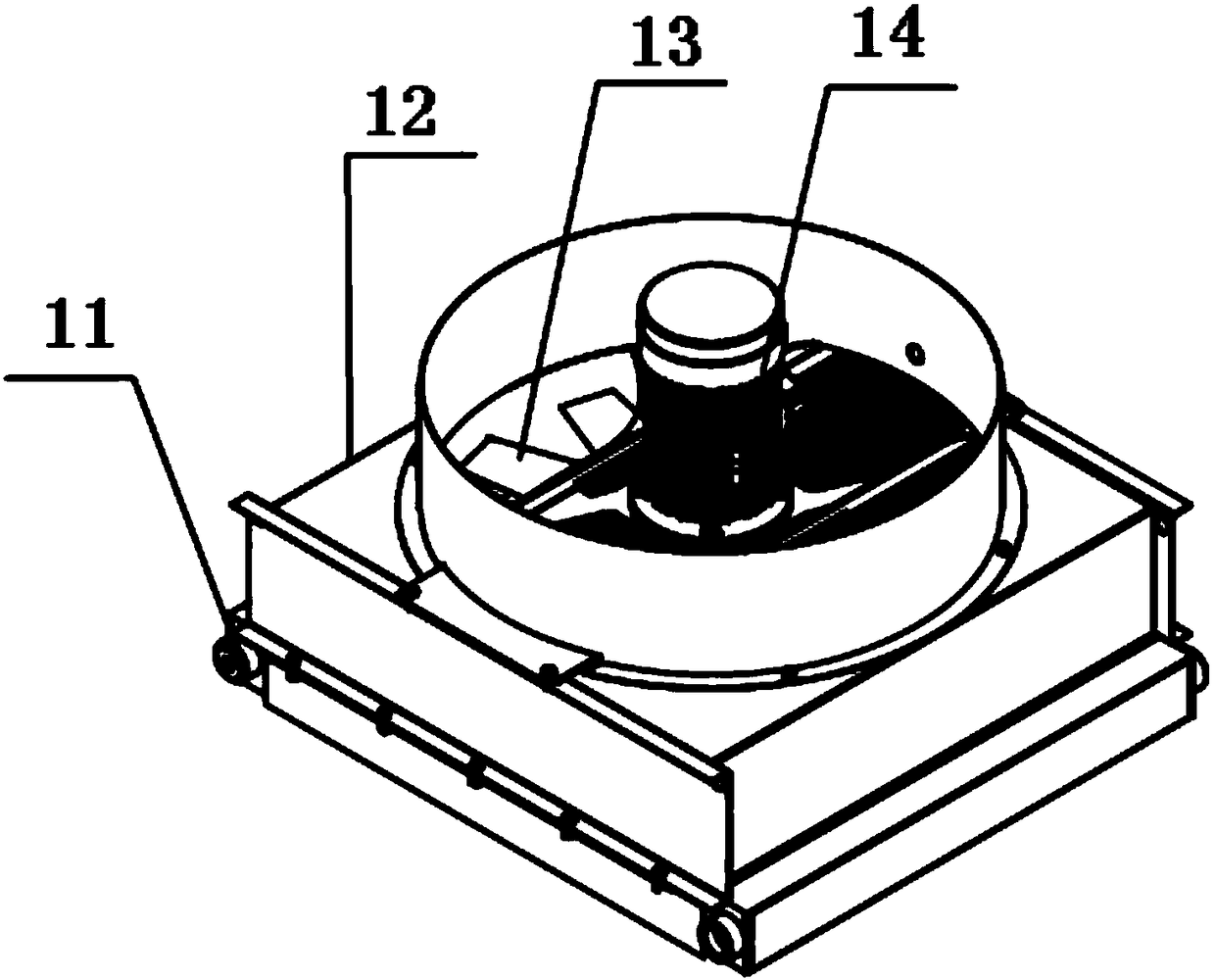

[0028] Refer to attached Figures 1 to 3 As shown, the heat exchange mechanism of the wind power gearbox in this embodiment is arranged inside the nacelle of the wind power generating set, which includes a heat exchange assembly 1 and an air inlet channel 2 and an air outlet channel respectively connected to the air inlet and air outlet of the heat exchange assembly 1 3.

[0029] The heat exchange assembly 1 is arranged outside the gear box 5 , and in this embodiment is fixedly arranged above the gear box 5 through the bracket 4 . Of course, it can also be fixed on other fixed parts inside the nacelle.

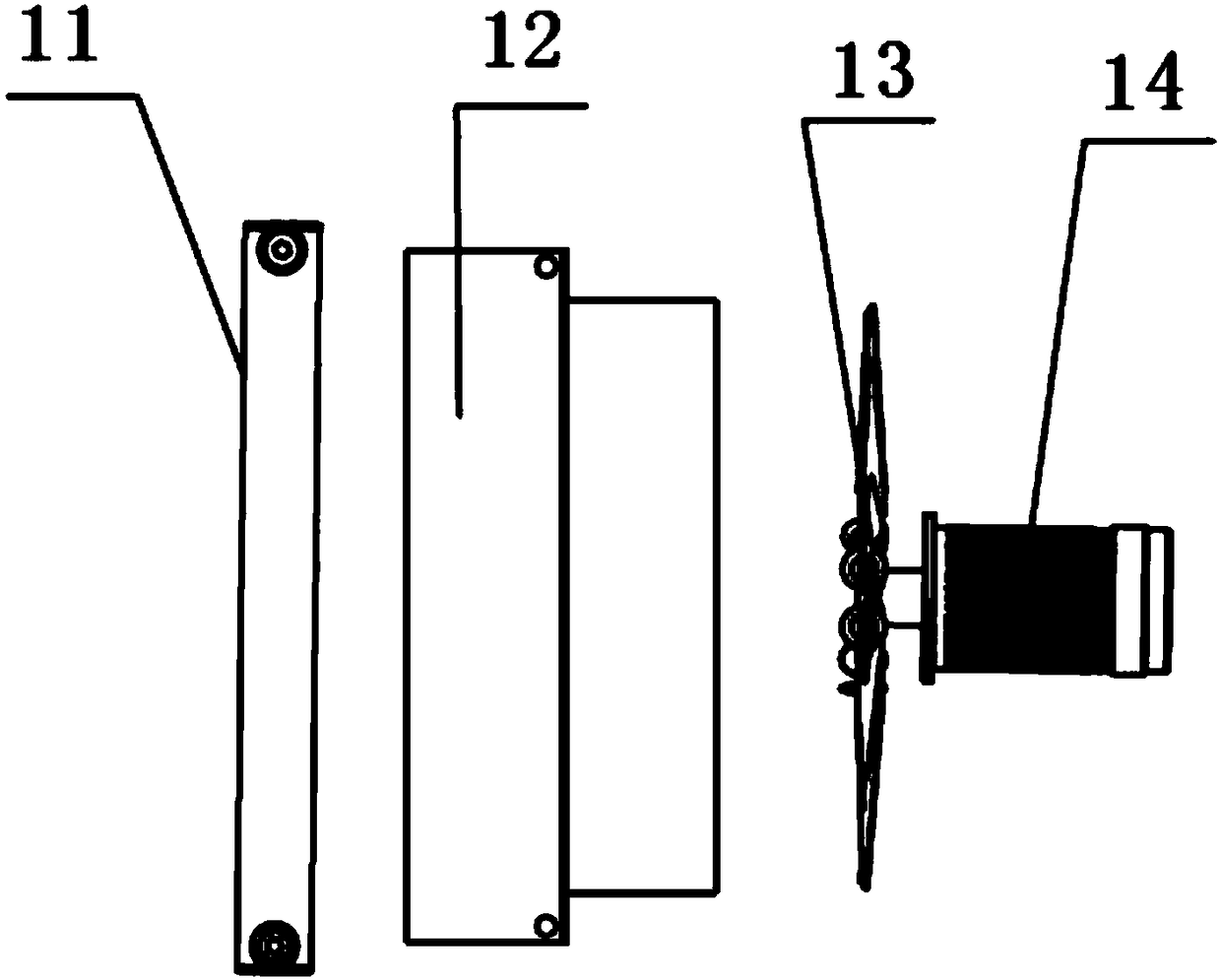

[0030] The heat exchange assembly 1 includes a heat exchange co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com