Spherical scanner and three-dimensional scanning system

A scanner and sphere technology, applied in the field of optical scanning, can solve problems such as cumbersome process of pasting reflective markers, inapplicability of high-precision equipment and cultural relics, precision measurement cannot meet the requirements, etc., to achieve expandable working space, simple structure, Aesthetically pleasing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

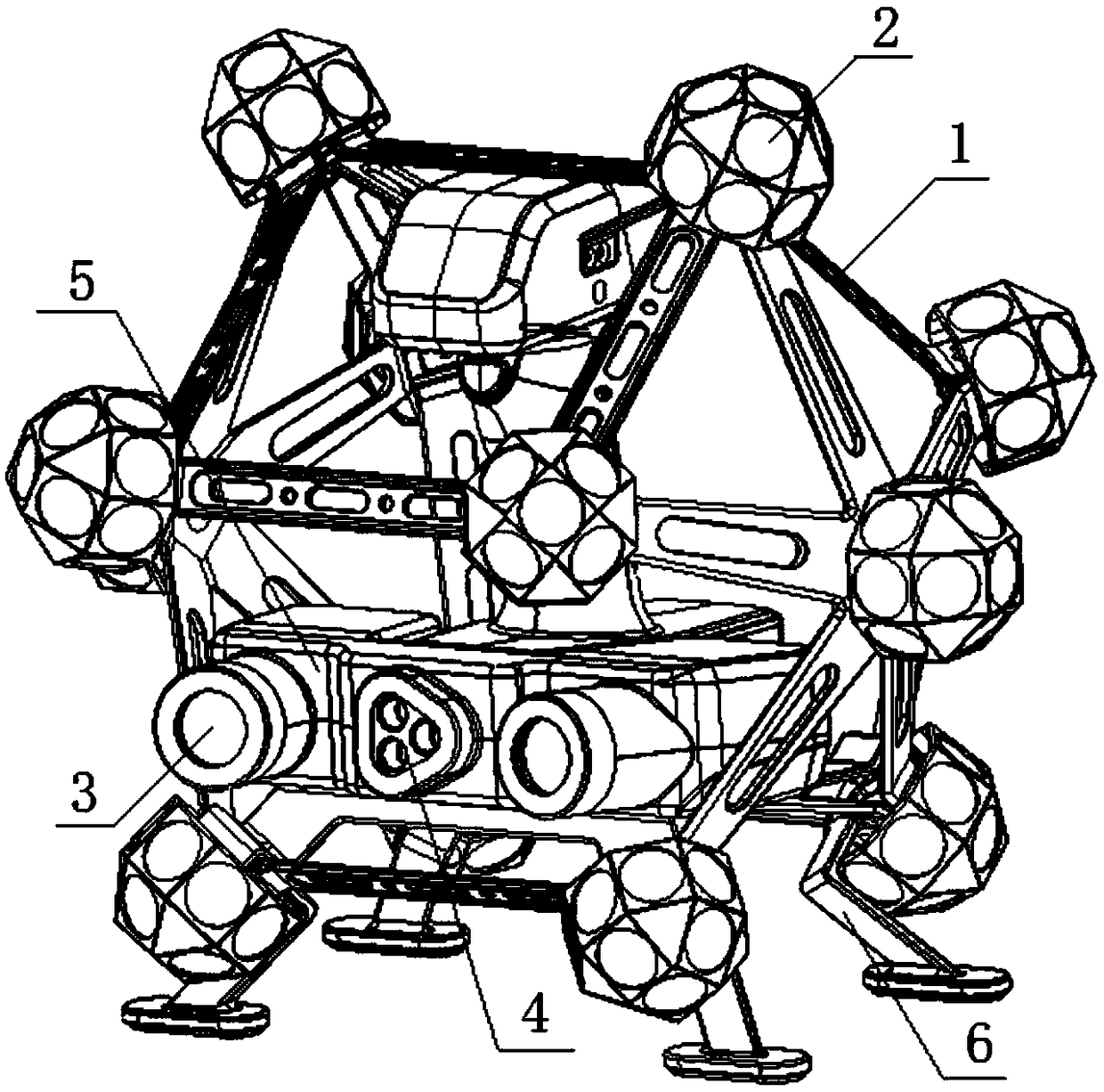

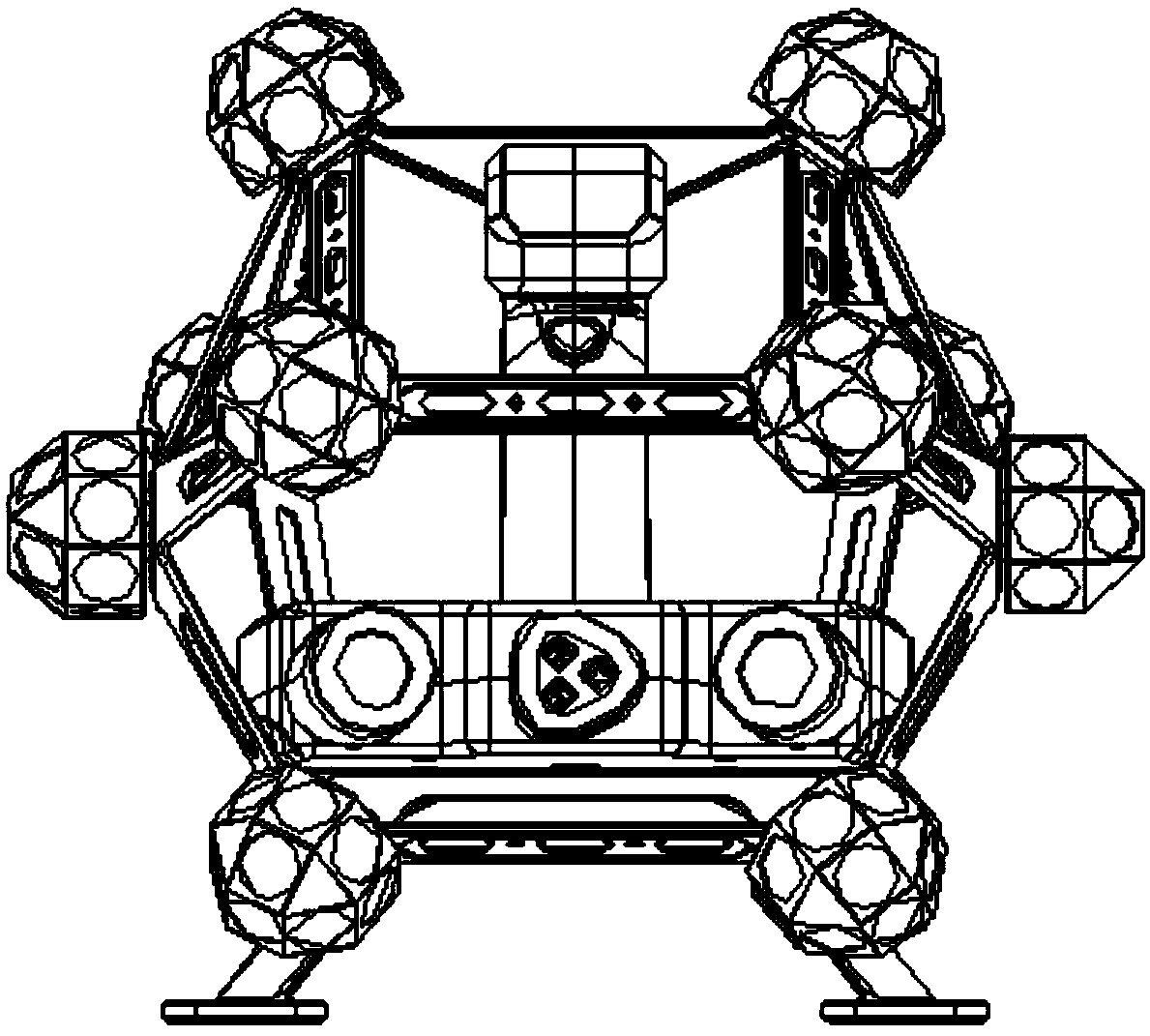

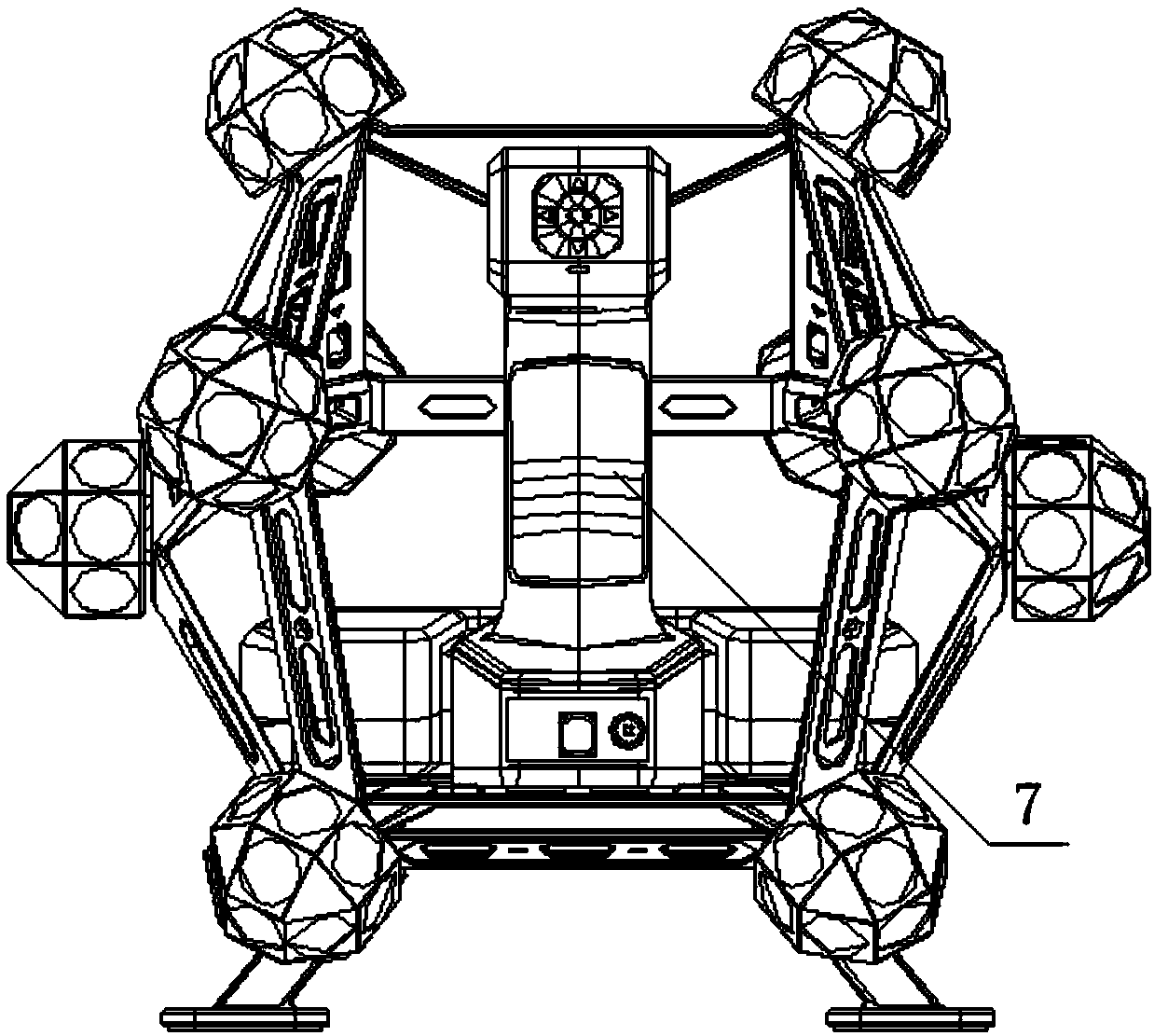

[0040] Such as Figure 1 to Figure 8 As shown, a spherical scanner includes a hollow polyhedron-shaped main body 1, a plurality of target balls 2, two cameras 3 and a scanner 4, and a plurality of target balls 2 are arranged on the vertices of the main body 1 in one-to-one correspondence position, the surface of the target ball 2 is provided with a plurality of mark reflective points, the two cameras 3 and the scanner 4 are all arranged in the main body 1, and the two cameras 3 and the scanner 4 are connected with the The main body 1 is connected, and the lenses of the two cameras 3 and the emitting ends of the scanner 4 are set towards the same side of the main body 1 .

[0041] In the present invention, through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com