Energy-saving micro spray head

A technology of micro-sprinklers and sprinklers, applied in horticulture, botanical equipment and methods, cultivation, etc., can solve the problems of high energy consumption, achieve the effect of improving irrigation quality, simple structure, and easy to popularize and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

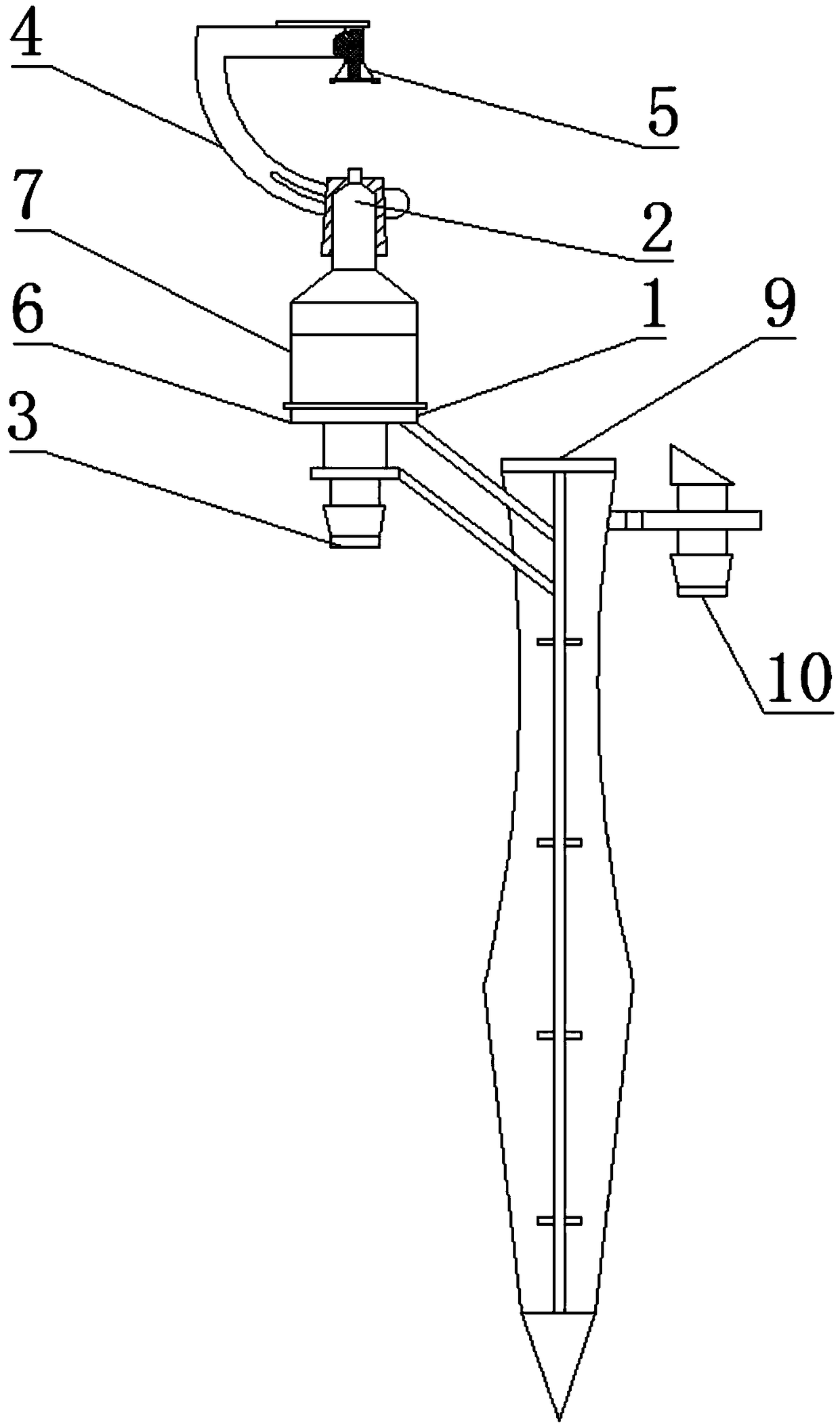

[0046] An energy-saving micro-spray head, comprising a nozzle base 1, a nozzle 2 is arranged on the top of the nozzle base 1, a water inlet pipe 3 is arranged on the bottom of the nozzle base 1, the nozzle 2 communicates with the water inlet pipe 3, and a bracket 4 is also arranged on the nozzle 2, and the bracket 4 A refraction table 5 is correspondingly arranged above the nozzle 2; a jet regulator is arranged inside the nozzle 2, and the jet regulator is used to change the rotating water flow into a non-rotating direct current.

[0047] In this embodiment, a jet regulator is provided inside the nozzle 2 of the existing micro-spray head, and the jet regulator is used to change the rotating water flow into a non-rotating water flow. In this embodiment, the water flow passes through the jet regulator under the action of the working pressure, and the jet regulator changes the rotating water flow into a non-rotating water flow to be injected from the nozzle 2, and the injected non...

Embodiment 2

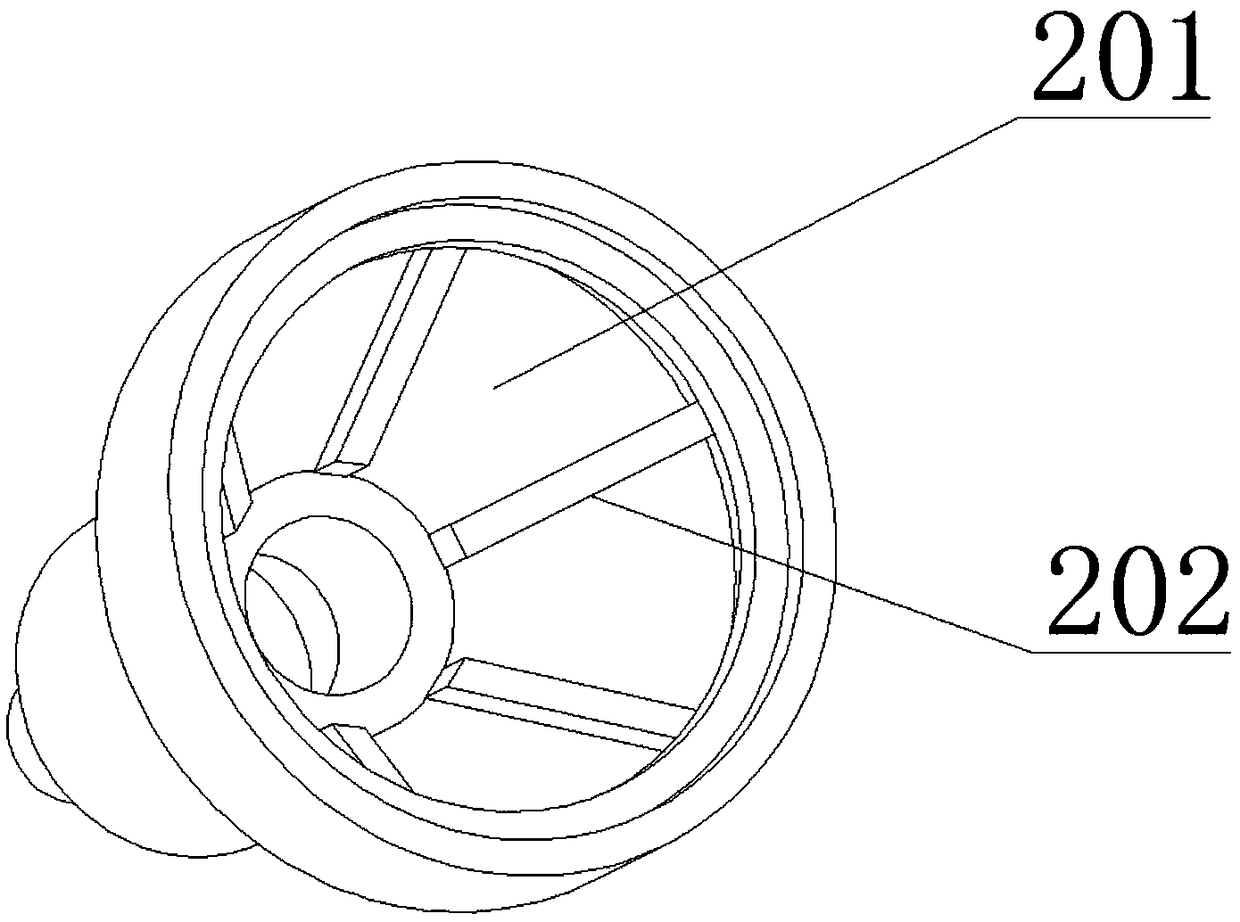

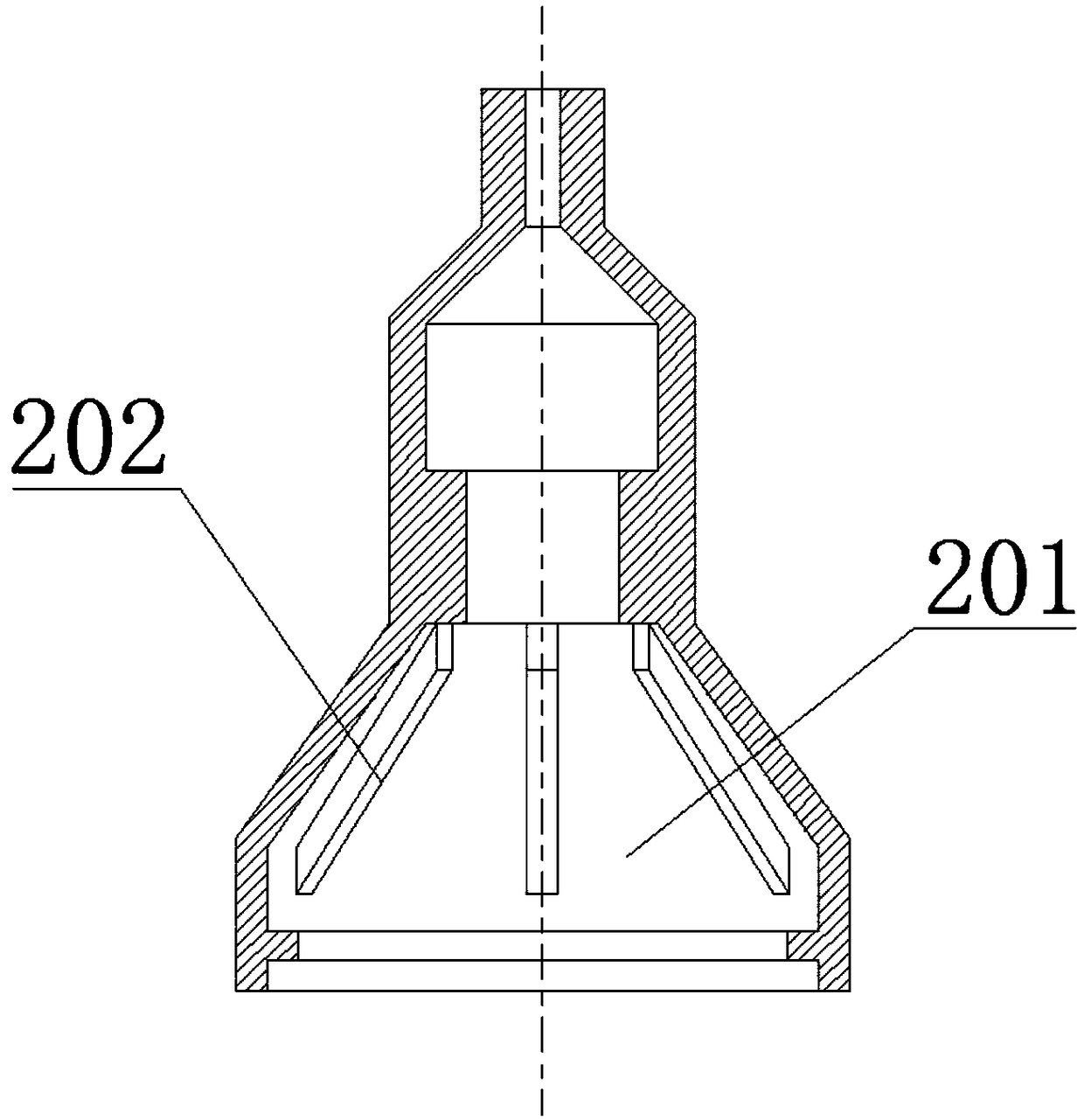

[0049] On the basis of Embodiment 1, the jet regulator includes an inverted trumpet-shaped constriction part 201, the inner wall of the constriction part 201 is provided with several ribs 202 in the circumferential direction, and grooves are formed between two adjacent ribs 202, The axis of the ribs 202 is a straight line, and the axis of each rib 202 is coplanar with the axis of the contraction part 201 .

[0050] In this embodiment, when the rotating water flow hits the ribs 202 arranged in the circumferential direction of the side wall, it will be forced to stop rotating, and flow to the outlet of the nozzle 2 along the channel between the ribs 202, and each rib 202 The axis of is coplanar with the axis of constriction 201 . Therefore, the rotating water flow does not rotate and becomes straight. The structure is simple, the jet adjustment effect is good, and it is convenient for production, and it has little influence on the structure of the micro-spray head in the prior a...

Embodiment 3

[0052] On the basis of Embodiment 1, the refraction table 5 is set in a concave table shape.

[0053] In this embodiment, because the refraction platform 5 of the micro-sprinkler in the prior art is flat or convex, the purpose is to obtain a larger spraying area, but in the hillside platform terrain, the gardens are distributed on the hillside platform, Therefore, the spraying area of the existing micro-spray head is too large, which will cause the sprayed water of the micro-spray head of the previous step to be sprayed on the next step, and some water will be irrigated ineffectively, which wastes water resources. In this embodiment, the refraction table 5 is changed into a concave table shape, and the spraying area is greatly reduced, which is suitable for use on hillside terraces, so that the sprayed water can be effectively used.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com