Production process of powdered honey

A production process and technology of honey, which is applied in the field of production process of powdered honey, can solve the problems of complex preparation process technology, not easy to carry, high water content, etc., and achieve the effect of simple process, thorough drying and high powdering efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

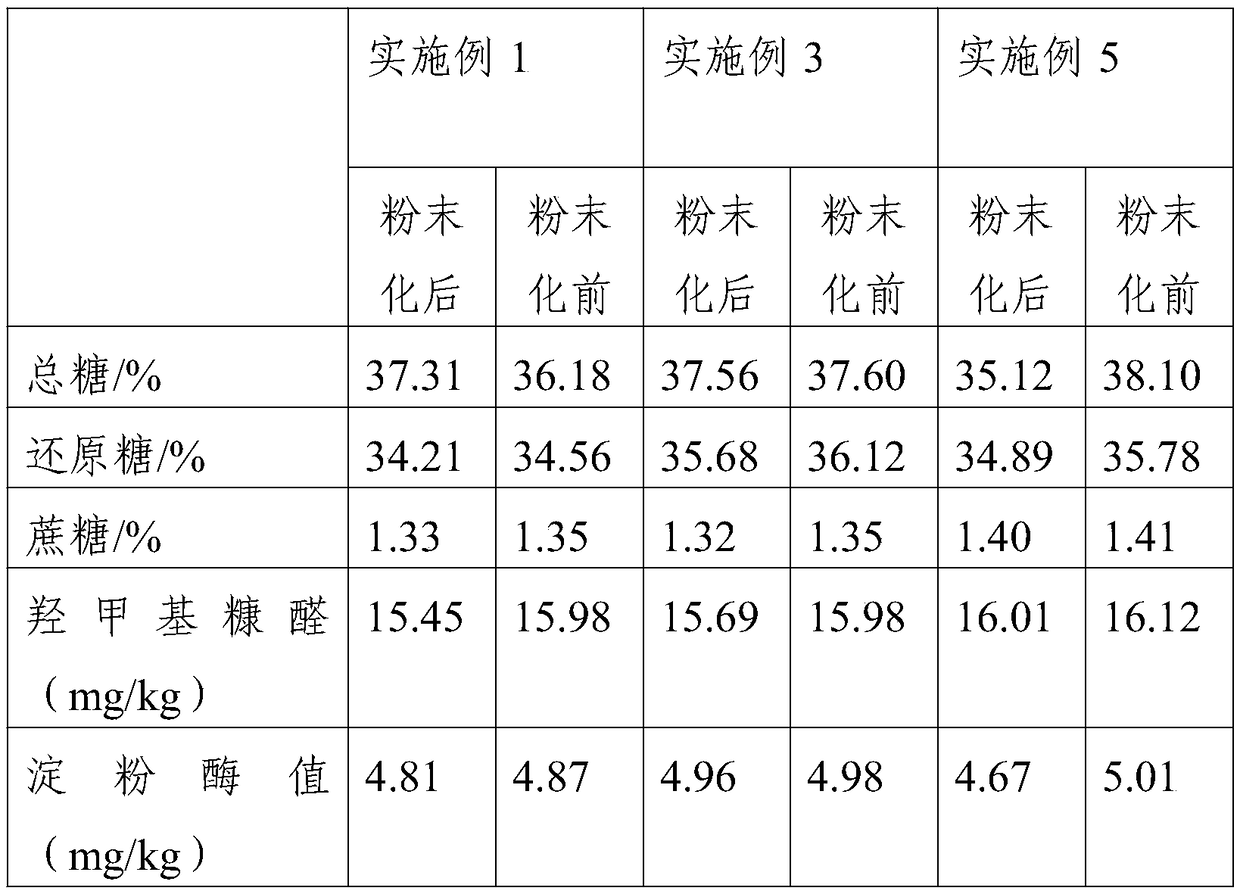

Examples

Embodiment 1

[0019] The invention provides a kind of production technology of powdery honey, and this production technology comprises the steps:

[0020] (1) Put fresh honey into the container, then put the container with fresh honey into the constant temperature pool, and keep the temperature of the constant temperature pool at 45°C;

[0021] (2) filtering the melted honey in step (1), removing bee carcasses, beeswax and pollen grains in the honey;

[0022] (3) Add cooled boiled water and cyclodextrin in sequence to the filtered clean honey, heat to 45°C, and then stir evenly;

[0023] (4) The mixed solution stirred uniformly in the step (3) is dried by a spray drying method to obtain honey powder.

[0024] The temperature of boiled water in the step (3) is 45°C.

[0025] In the step (3), the mass ratio of cyclodextrin to honey is 12:8, and the mass ratio of honey to boiled water is 8:1.

[0026] In the step (3), add boiled water into clean honey, heat to 45° C., stir evenly, then add ...

Embodiment 2

[0031] The invention provides a kind of production technology of powdery honey, and this production technology comprises the steps:

[0032] (1) Put fresh honey into the container, then put the container with fresh honey into the constant temperature pool, and keep the temperature of the constant temperature pool at 65°C;

[0033] (2) filtering the melted honey in step (1), removing bee carcasses, beeswax and pollen grains in the honey;

[0034] (3) Add cooled boiled water and cyclodextrin in sequence to the filtered clean honey, heat to 55°C, and then stir evenly;

[0035] (4) The mixed solution stirred uniformly in the step (3) is dried by a spray drying method to obtain honey powder.

[0036] The temperature of boiled water in the step (3) is 55°C.

[0037] The mass ratio of cyclodextrin and honey in the step (3) is 15:8, and the mass ratio of honey and boiled water is 8:3.

[0038] In the step (3), add boiled water into clean honey, heat to 55° C., stir evenly, then add...

Embodiment 3

[0043] The invention provides a kind of production technology of powdery honey, and this production technology comprises the steps:

[0044] (1) Put fresh honey into the container, then put the container with fresh honey into the constant temperature pool, and keep the temperature of the constant temperature pool at 50°C;

[0045] (2) filtering the melted honey in step (1), removing bee carcasses, beeswax and pollen grains in the honey;

[0046] (3) Add cooled boiled water and cyclodextrin in sequence to the filtered clean honey, heat to 47°C, and then stir evenly;

[0047] (4) The mixed solution stirred uniformly in the step (3) is dried by a spray drying method to obtain honey powder.

[0048] The temperature of boiled water in the step (3) is 47°C.

[0049] In the step (3), the mass ratio of cyclodextrin to honey is 13:8, and the mass ratio of honey to boiled water is 8:1.

[0050] In the step (3), add boiled water into clean honey, heat to 47° C., stir evenly, then add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com