Gas distribution device suitable for dividing wall column

A gas distribution device and technology for gas distribution, applied in the field of chemical rectification, can solve the problems of too many transmission parts, unbalanced adjustment, gas-liquid phase separation, etc., and achieve the effect of less transmission parts, simple structure and flexible deployment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

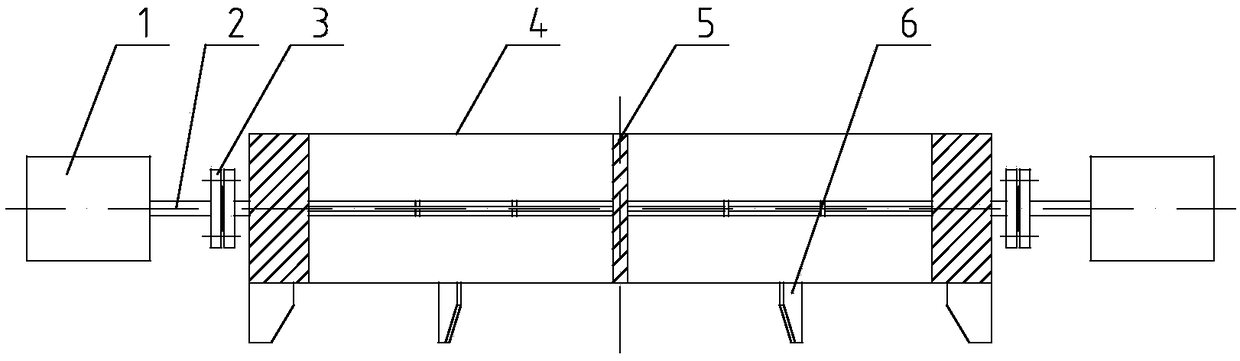

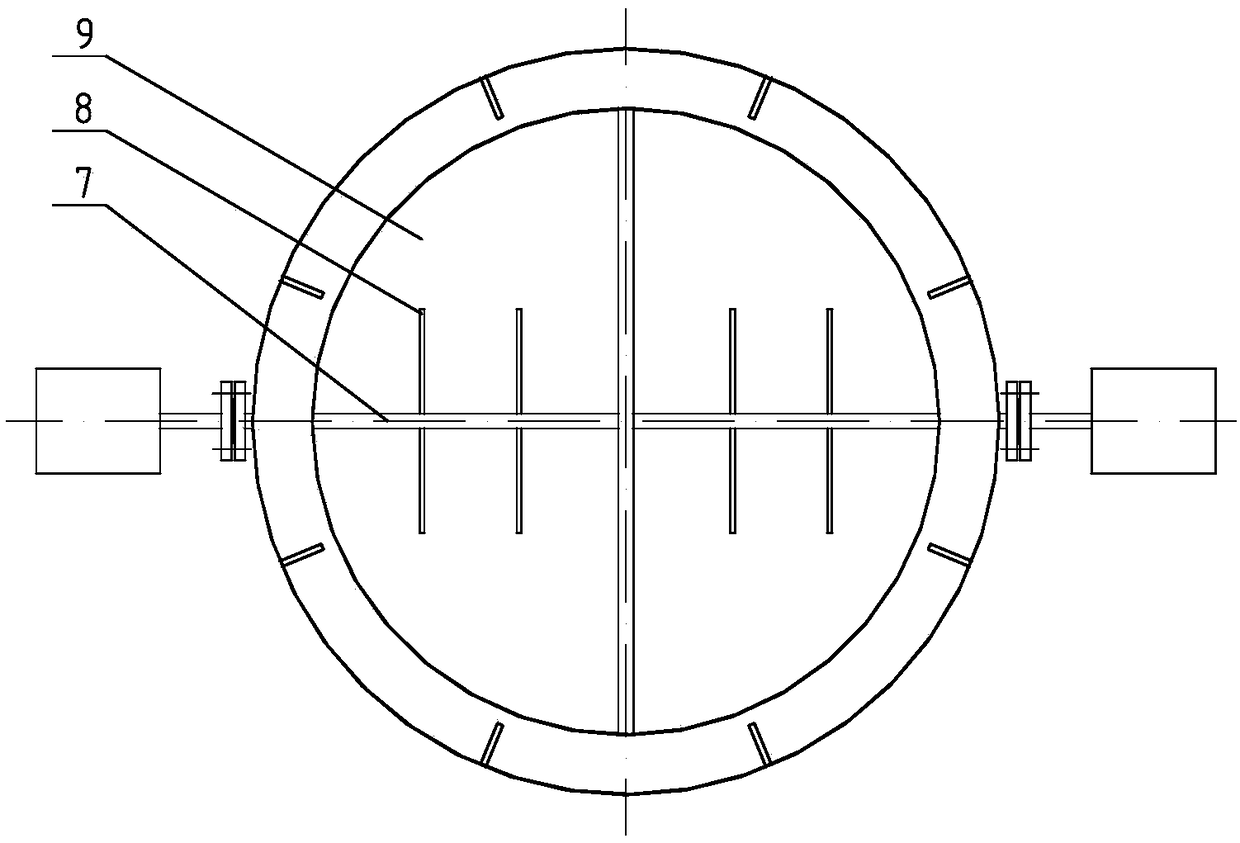

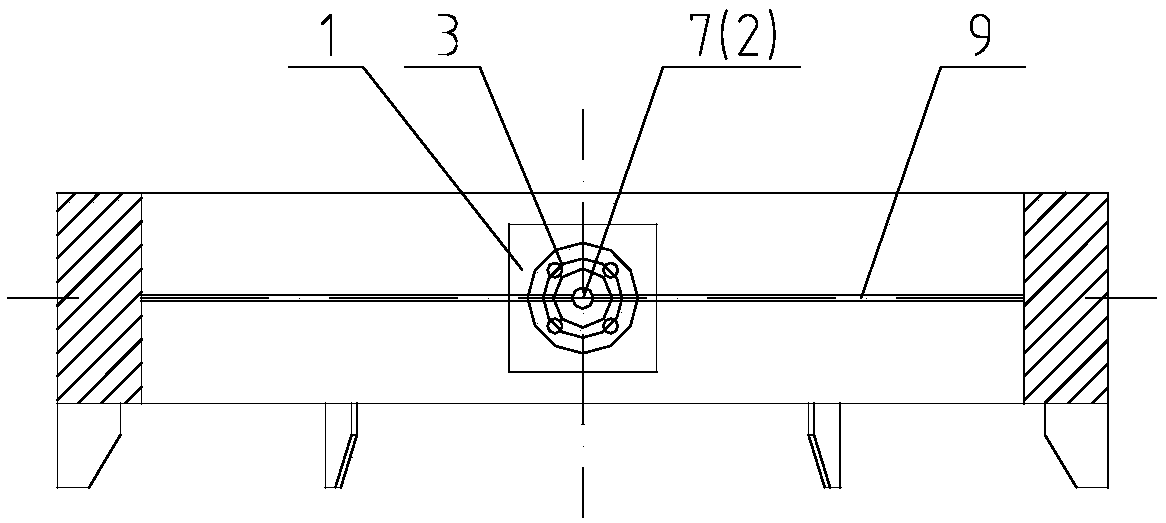

[0050] Embodiment 1: In this embodiment, the diameter of the next-door tower is 800 mm, the outer diameter of the gas distribution device housing 4 is 796 mm, the inner diameter is 736 mm, and the height is 100 mm. The thickness of the baffle plate 5 at the center of the housing 4 is 20 mm. The surface and the lower surface are respectively flush with the upper and lower surfaces of the shell, and the upper surface coincides with the lower surface of the dividing plate of the next-door tower, so as to ensure that the materials on both sides of the baffle plate 5 are isolated from each other. There are circular through holes with a diameter of 15 mm on both sides of the horizontal direction of the housing 4 and the tower body, and a rotating shaft 7 is arranged in the middle of the circular through hole. The diameter of the rotating shaft 7 is 15 mm, and the outer side of the rotating shaft 7 extends out of the tower. body, and is connected with a shaft coupling 3, and the outer...

Embodiment 2

[0052] Embodiment 2: In this example, the diameter of the next-door tower is 2000mm, the outer diameter of the gas distribution device housing 4 is 1996mm, the inner diameter is 1896mm, and the height is 200mm. The thickness of the baffle plate 5 in the center of the housing 4 is 30mm. The side and the tower body are respectively provided with a circular through hole with a diameter of 20 mm, the diameter of the rotating shaft 2 7-2 passing through the circular through hole is 20 mm, the depth of the groove on the baffle plate 5 is 5 mm, and the rotating shaft 2 7-2 is inserted into the in the groove and can rotate freely. The device adopts a three-blade structure, and in addition to the rotating shaft 2 7-2, it also includes a rotating shaft 1 7-1 and a rotating shaft 3 7-3, both of which have a diameter of 20 mm. One end of -3 is inserted into the groove in the casing 4, and the other end is inserted into the groove in the baffle plate 5, and can rotate freely. Blade 1 9-1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com