Anti-icing film and preparation method thereof

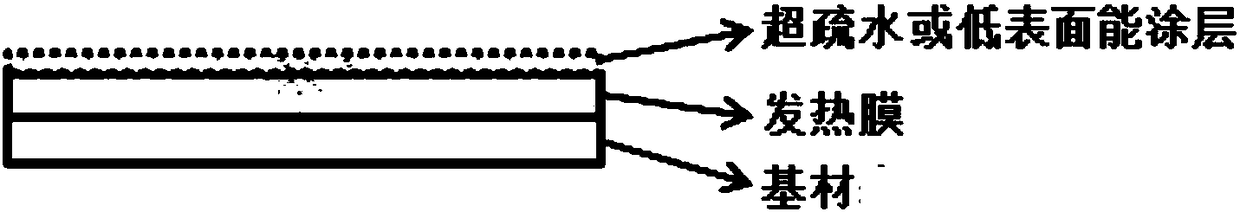

An anti-icing and anti-icing technology, which is applied to pre-treatment surfaces, devices for applying liquid to surfaces, coatings, etc., can solve the problems of single anti-icing and de-icing effect, high energy consumption, and inability to achieve prevention, etc. Achieve the effect of solving single anti-icing and deicing, high heating efficiency and good anti-icing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Clean the surface of the heating film with absolute ethanol until the surface is clean, and let it dry naturally;

[0019] Under the compressed air of 0.5MPa, spray WNS on the surface of the heating film with a low-pressure spray gun;

[0020] Curing in an oven at 80°C under normal pressure for 60 minutes to obtain the anti-icing film; test the water contact angle, and the film is energized to generate heat to test the heating efficiency.

Embodiment 2

[0022] Clean the surface of the heating film with absolute ethanol until the surface is clean, and let it dry naturally;

[0023] Under the compressed air of 0.3MPa, spray NC3052 on the surface of the heating film with a low-pressure spray gun;

[0024] Curing in an oven at 80°C under normal pressure for 50 minutes to obtain the anti-icing film; test the water contact angle, and the film is energized to generate heat to test the heating efficiency.

Embodiment 3

[0026] Clean the surface of the heating film with absolute ethanol until the surface is clean, and let it dry naturally;

[0027] Brush a layer of polydimethylsiloxane (PDMS) on the surface of the heating film;

[0028] Curing in an oven at 70°C under normal pressure for 70 minutes to obtain an anti-icing film; test the water contact angle, and test the heating efficiency of the film when it is energized and heated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com