Photothermal and electrothermal hybrid DC anti-icing composite insulator

A composite insulator and hybrid technology, applied in insulators, suspension/strain insulators, circuits, etc., can solve the problems of easy occurrence of ice flashes, decline in electrical performance of composite insulators, and endanger the safe operation of transmission lines. Ice flashover accident, the effect of excellent anti-pollution flashover capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

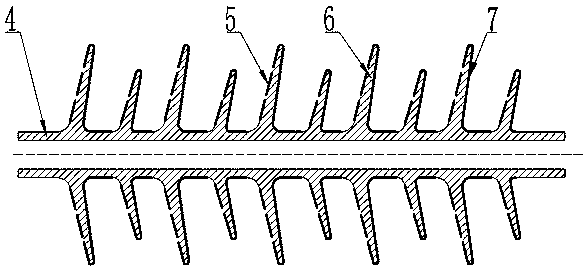

[0028] figure 1 In the photothermal layer 5 used by 30 parts of FeMnCuO 4 Micropowder (particle size 0.6 ~ 1.8μm) and 70 parts of ordinary RTV paint are mixed in a kneader at 120°C for 2 hours, then ground and dispersed to obtain an inorganic metal oxide RTV paint coating. The semiconductor graphite RTV coating used is prepared by mixing 22 parts of conductive graphite powder (particle size 0.6-1.8 μm) and 78 parts of ordinary RTV coating in a kneader at 120°C for 2 hours, then grinding and dispersing. structured as figure 1 As shown, the insulator is composed of large umbrellas with a diameter of 130mm and small umbrellas with a diameter of 100mm alternately, and the spacing between the umbrellas is 40mm. 4 ) RTV coating, the lower surface of the shed and the sheath 4 are coated with semiconducting graphite RTV coating to form a semiconducting layer 7, and the volume resistivity of the semiconducting RTV coating is 1.36×10 5 Ω·m, the middle layer of the umbrella skirt is a...

Embodiment 2

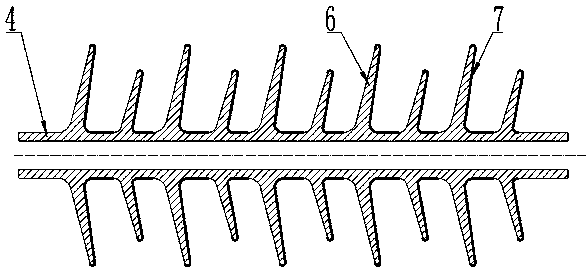

[0030] figure 2 Among them, the inorganic metal oxide RTV coating used consists of 25 parts of FeMnCuO 4 Fine powder (particle size 0.6-1.8 μm) and 75 parts of ordinary RTV paint are mixed in a kneader at 120 ° C for 2 hours and then ground and dispersed. The semiconductor graphite RTV coating used is made of 21 parts of conductive graphite powder (particle size 0.6-1.8 μm ) and 79 parts of ordinary RTV coatings were mixed in a kneader at 120°C for 2 hours and then ground and dispersed; the structure is as follows figure 2 As shown, the insulator is composed of large umbrellas with a diameter of 130mm and small umbrellas with a diameter of 100mm alternately. The spacing between the umbrellas is 38mm. The silicone rubber layer 6 on the upper surface and the sheath 4 are ordinary silicone rubber, and the lower surface of the shed and the sheath are coated with semiconductor graphite RTV coating. As the semiconductor layer 7, the volume resistivity of the semiconductor RTV pai...

Embodiment 3

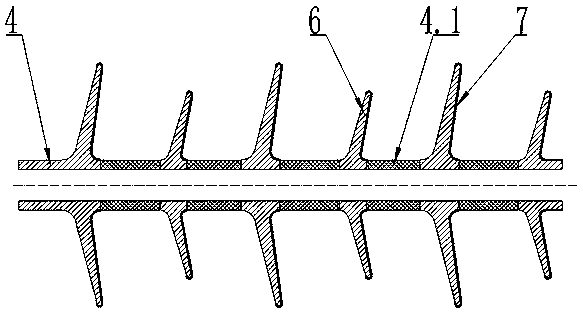

[0032] image 3 Among them, the semiconductor graphite RTV coating used is made of 21 parts of conductive graphite powder (particle size 0.6 ~ 1.8 μm) and 79 parts of ordinary RTV coating in a kneader after kneading at 120 ° C for 2 hours and then ground and dispersed. The semiconductor graphite silicone rubber used is made of 13 parts of conductive graphite powder (particle size 0.6 ~ 1.8 μm) and 87 parts of ordinary silicone rubber compound were mixed in a kneader at 150 ° C for 2 hours, and the middle part of the sheath 4.1 was made of 12 parts of graphite powder (particle size 0.6~1.8μm) and 88 parts of silicone rubber compound mixed in a kneader at 150°C for 2 hours; the structure is as follows image 3 As shown, the insulator is composed of large umbrellas with a diameter of 130mm and small umbrellas with a diameter of 100mm alternately, and the spacing between the umbrellas is 52mm. The silicone rubber layer 6 on the upper surface and the sheath 4 at both ends are ordin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com