A kind of anti-icing functional structure and its preparation method and application

A functional, anti-icing technology, applied in the direction of manufacturing tools, welding equipment, deicing devices, etc., can solve the problems of poor anti-icing effect, achieve the effect of not easy to freeze, delay crystallization nucleation, and reduce residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The invention provides a preparation method of an anti-icing functional structure, comprising the following steps:

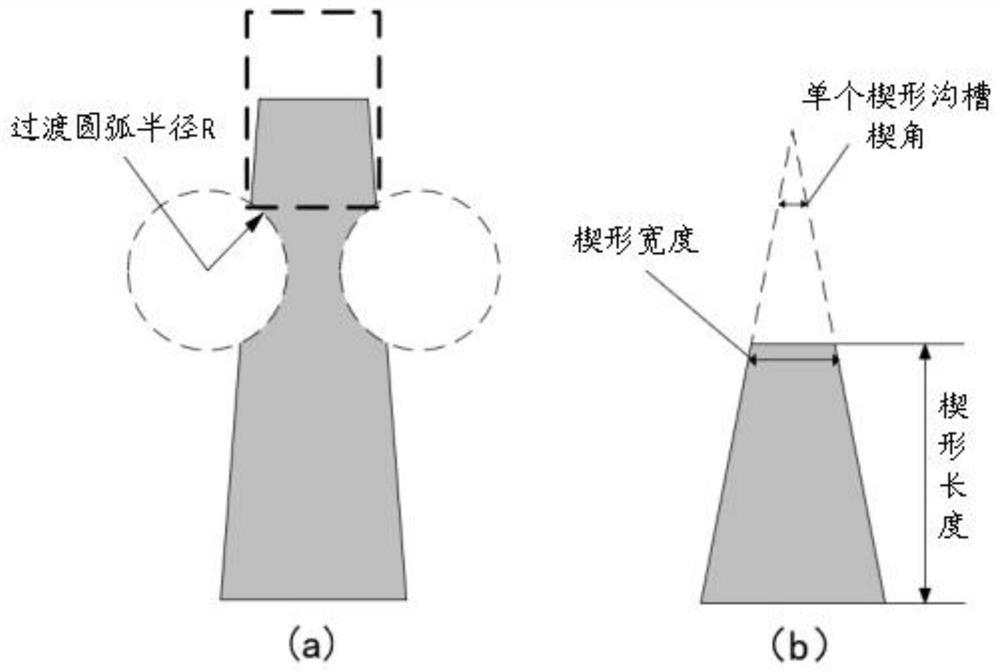

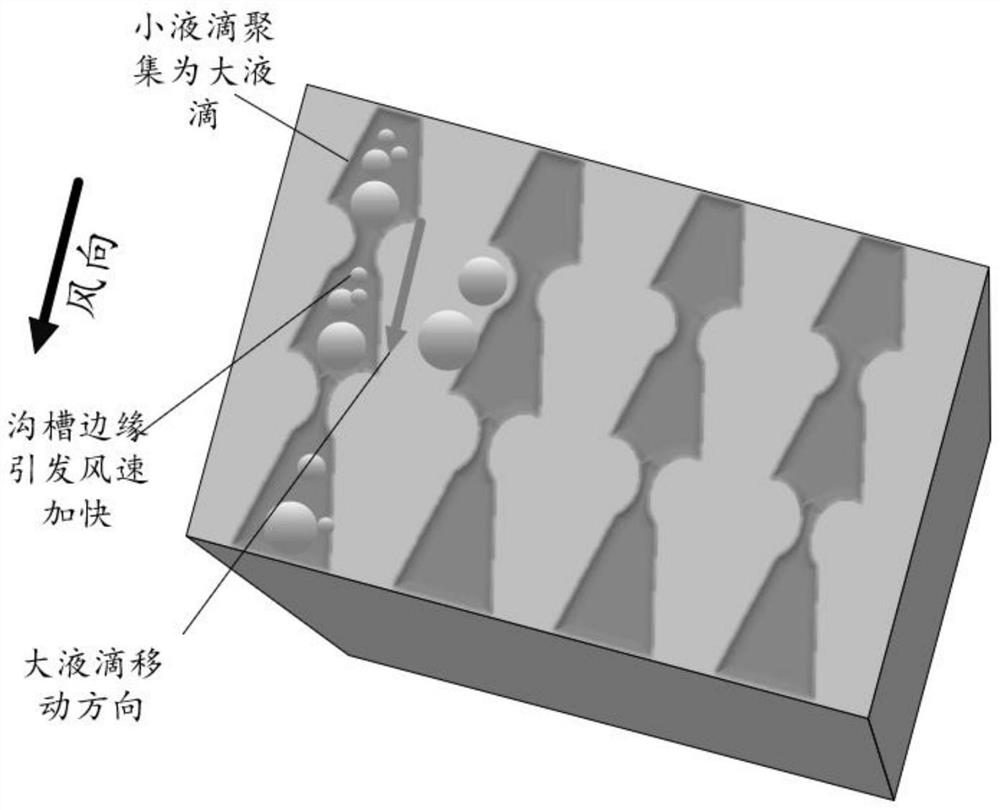

[0026] A wedge-shaped microstructure is prepared on the surface of the substrate, and a wedge-shaped microstructure layer is formed on the surface of the substrate; the wedge-shaped microstructure layer is formed by array-distributed wedge-shaped microstructures, and the wedge-shaped microstructure includes a plurality of series-connected wedge-shaped grooves, connected in series In two adjacent wedge-shaped grooves, along the water flow direction, the wide end of one wedge-shaped groove is connected to the narrow end of the other wedge-shaped groove through a transition arc;

[0027] Prepare nanoscale lattices distributed in an array on the surface of the wedge-shaped microstructure layer, and form a nanoscale lattice layer on the surface of the wedge-shaped microstructure layer;

[0028] The substrate with the nanoscale lattice structure layer on the su...

Embodiment 1

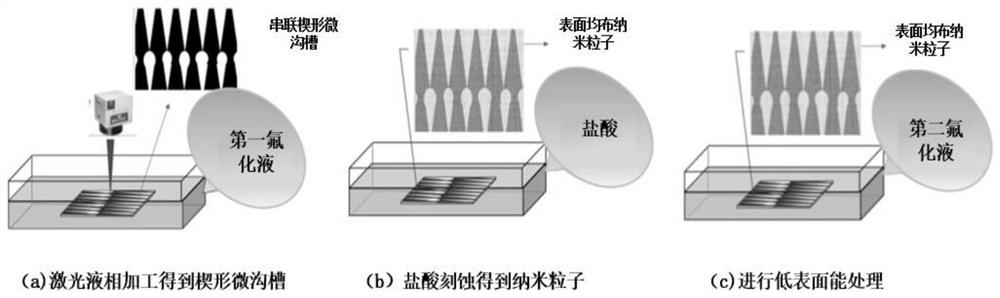

[0043] according to image 3 The flow chart shown prepares a functional surface, including the following steps:

[0044] Fluorosilane F1060 (CFH 2 CH 2 -Si(OC 2 h 5 ) 3 ) as the solute and toluene as the solvent, prepare a fluorinated solution with a mass fraction of 1.5% (referred to as the first fluorinated solution) and a fluorinated solution with a mass fraction of 0.2% (referred to as the second fluorinated solution);

[0045] Taking the aluminum alloy 2524 for aviation as the substrate, immerse the substrate in the first fluorinated liquid, and make the first fluorinated liquid submerge the upper surface of the substrate by 1 mm, and use laser liquid phase processing method on the substrate The wedge-shaped microstructure was processed by surface scanning, and a wedge-shaped microstructure layer was formed on the surface of the substrate; the obtained substrate was taken out from the first fluorinated liquid, dried with high-purity nitrogen, and then heated in a hol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com