Method for improving yield deformation resistance of water heater glassed steel inner container welded joint

A water heater liner, welding joint technology, applied in welding equipment, workpiece edge parts, metal processing equipment and other directions, can solve the problems of low yield deformation resistance, easy cracking and leakage of welded joints, etc., to prolong fatigue life and overcome the yield of welded joints. Decreased deformation resistance and easy manipulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1, the enamel steel base plate of the water heater is a pickled steel plate with the brand name BTC330R produced by Baoshan Iron and Steel Co., Ltd., and the thickness of the steel plate is 1.8mm.

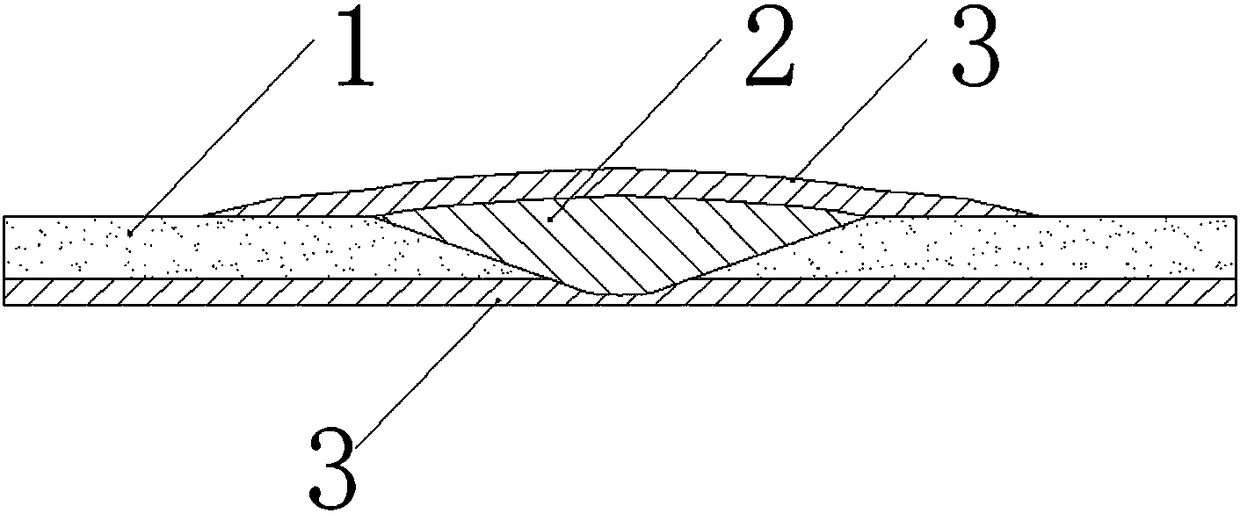

[0022] refer to figure 1 , a method for improving the yield deformation resistance of welded joints of enamelled steel tanks of water heaters, comprising the following steps:

[0023] 1) Prepare the blank of the water heater liner, cut the enamel steel base plate 1 for the water heater liner according to the size of the water heater liner, splice and group the cut enamel steel base plate 1 for the water heater liner in sequence to form an I-shaped groove for welding; The paired enamel steel substrates 1 are welded to form a weld seam 2 by using a single-sided one-time welding forming process by plasma fusion welding to make a water heater inner tank blank;

[0024] 2) Carry out degreasing and activation treatment on the surface of the water heater liner blank in seq...

Embodiment 2

[0028] Example 2, the enamel steel plate of the water heater is pickled steel plate with the brand name BTC330R produced by Baoshan Iron and Steel Co., Ltd., and the thickness of the steel plate is 1.6mm.

[0029] refer to figure 1 , a method for improving the yield deformation resistance of welded joints of enamelled steel tanks of water heaters, comprising the following steps:

[0030]1) Prepare the blank of the water heater liner, cut the enamel steel base plate 1 for the water heater liner according to the size of the water heater liner, splice and group the cut enamel steel base plate 1 for the water heater liner in sequence to form an I-shaped groove for welding; The paired enamel steel substrates 1 are welded to form weld seams 2 by TIG argon arc welding fusion welding single-sided one-time welding forming process, and the water heater liner blank is made;

[0031] 2) Degreasing and activating the surface of the water heater liner blank in sequence, first place the wat...

Embodiment 3

[0035] Example 3, the enamel steel plate of the water heater is pickled steel plate with the brand name BTC330R produced by Baoshan Iron and Steel Co., Ltd., and the thickness of the steel plate is 1.5 mm.

[0036] refer to figure 1 , a method for improving the yield deformation resistance of welded joints of enamelled steel tanks of water heaters, comprising the following steps:

[0037] 1) Prepare the blank of the water heater liner, cut the enamel steel base plate 1 for the water heater liner according to the size of the water heater liner, splice and group the cut enamel steel base plate 1 for the water heater liner in sequence to form an I-shaped groove for welding; The paired enamel steel substrates 1 are welded to form a weld 2 by using MAG gas-shielded welding fusion welding single-sided one-time welding forming process to make a blank for the inner tank of the water heater;

[0038] 2) Carry out degreasing and activation treatment on the surface of the water heater l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com