Full-automatic thin film coiled material packaging production line

A packaging production line, film roll technology, applied in packaging, packaging machines, transportation packaging, etc., can solve the problems of neglecting defective products, heavy coil weight, heavy labor, etc., to reduce the amount of defective products, improve packaging efficiency, The effect of improving packaging quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

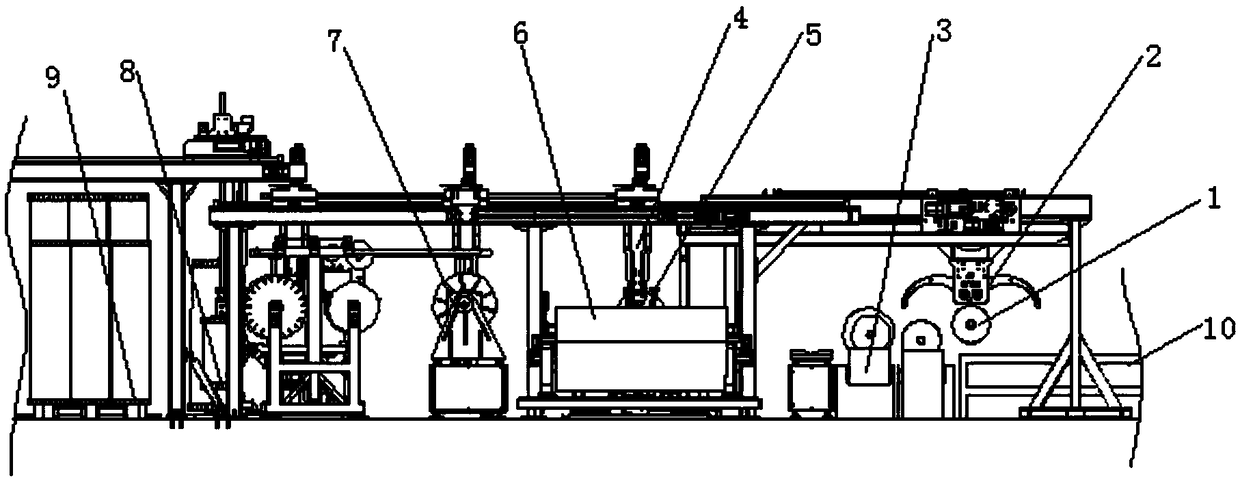

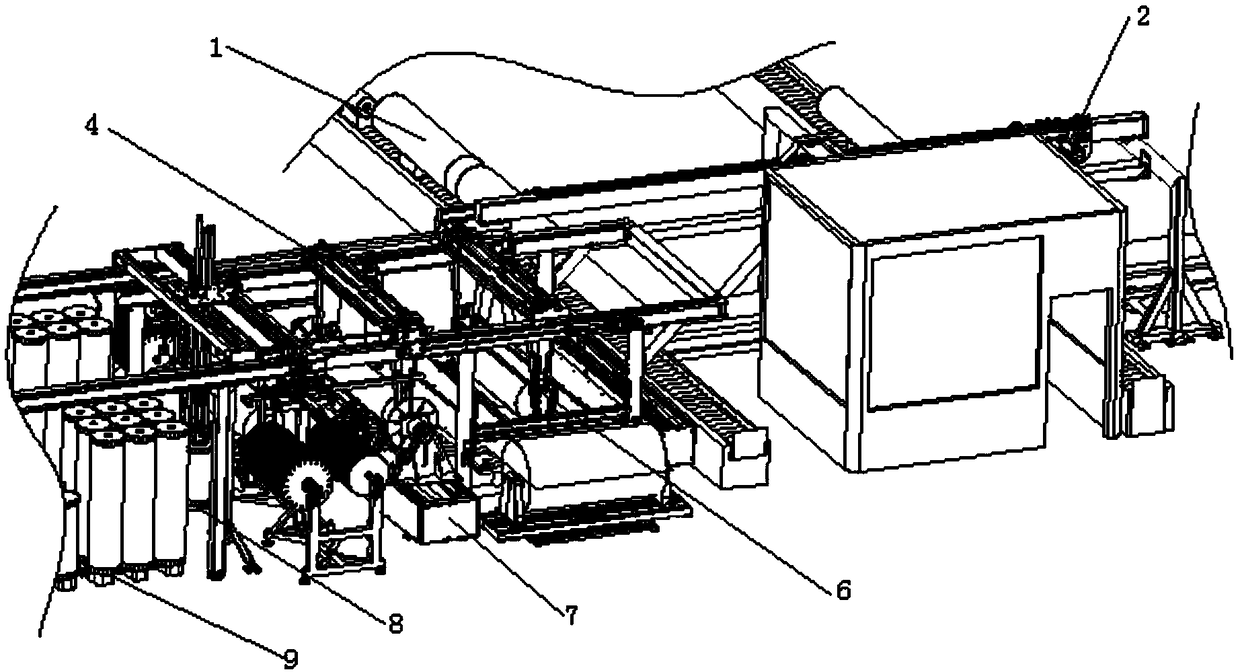

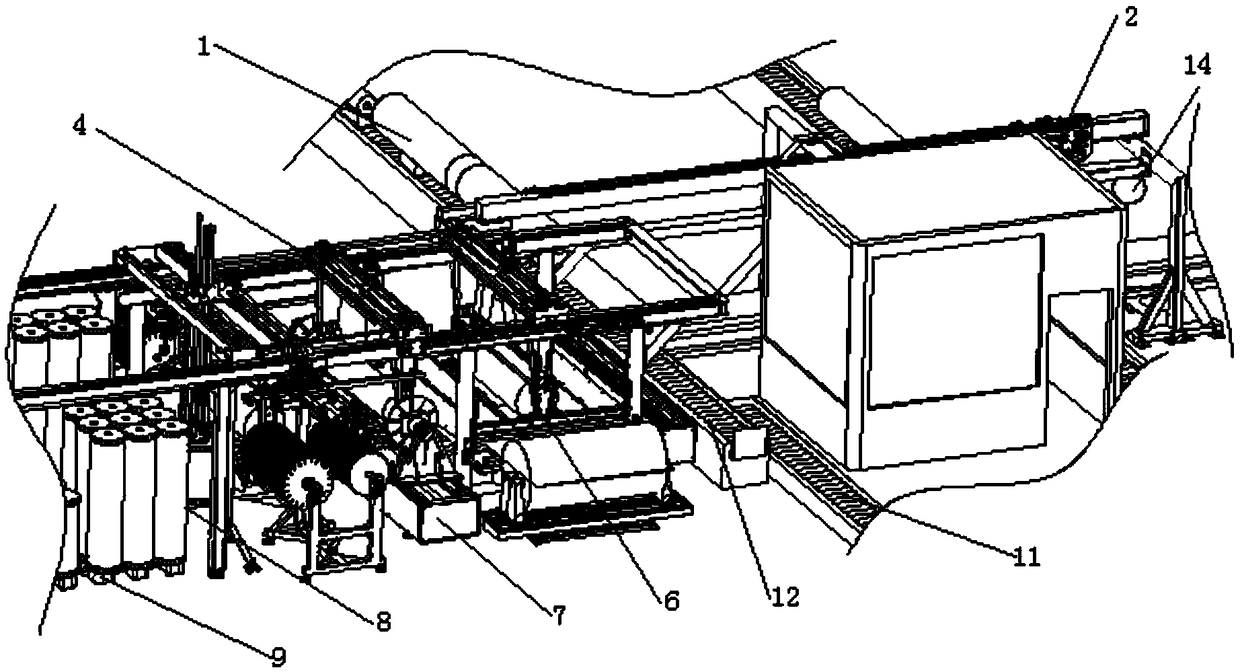

[0046] see Figure 1-5 , full-automatic film and coil packaging production line, including coil 1 rolled up and down from the slitting machine, including conveyor belt 10, positioning table station 3, air bubble film coating station 5, paper cover foam cushion buckle in sequence from right to left Combined station 7, turning table 8 and tray 9, the upper side of positioning table station 3 is provided with wrapping manipulator 2, the upper side of hot-melt mechanism 6 is provided with air bubble film covering station 5, and the upper side of air bubble film covering station 5 A lifting manipulator 4 is provided on the upper side, a stacking manipulator is provided on the upper side of the turning table 8, and a detection device is provided between the conveyor belt 10 and the positioning table station 3, which can realize fully automatic packaging mechanization and significantly improve packaging efficiency. In addition, Defective products can be detected in time through the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com