Fireproof sealing material and preparation method thereof

A fire blocking and mesoporous silica technology, applied in the field of blocking materials, can solve the problems of unsuitable use of lightweight partition walls or through-bearing boards, high compressive strength, and large specific gravity, and achieves the compressive strength index data. Reasonable, the effect of reducing compressive strength and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1: A fireproof sealing material, each component and its corresponding parts by weight are shown in Table 1, and it is prepared through the following steps:

[0041] Step 1, firstly add Portland cement to the mixer, and then add sodium gluconate for premixing to obtain a premix;

[0042] Step 2, according to the order of perlite powder, gypsum powder, clay powder and premix, all the raw materials are added into the spiral mixer, and stirred and mixed evenly;

[0043] Step 3: After stirring with the spiral mixer for 15 minutes, unload the bottom material in the spiral mixer, return to the spiral mixer and continue stirring for 10 minutes, and then discharge the material to obtain a fireproof plugging material.

[0044] Among them, the fineness of clay powder is 200 mesh, the fineness of perlite powder is 80 mesh, and the grade of Portland cement is 325.

Embodiment 2-5

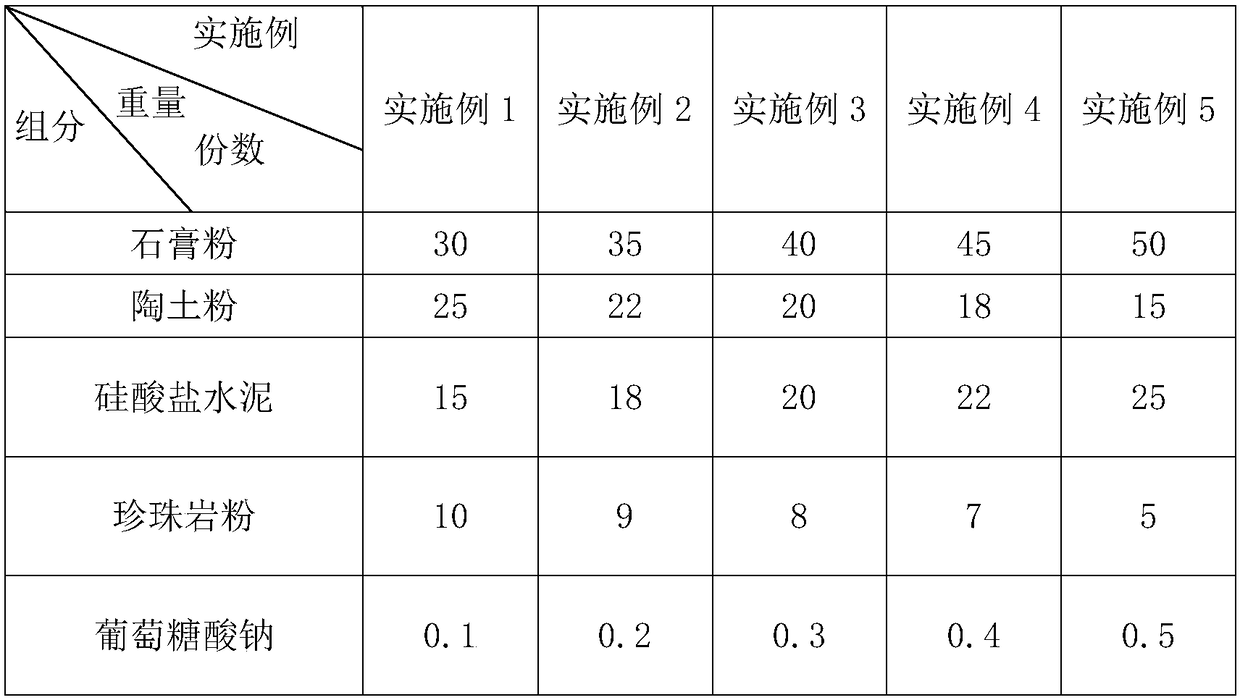

[0045] Embodiment 2-5: A fireproof sealing material, the difference from Embodiment 1 is that each component and its corresponding parts by weight are shown in Table 1.

[0046] Each component and parts by weight thereof in table 1 embodiment 1-5

[0047]

Embodiment 6

[0048] Embodiment 6: A fireproof sealing material, the difference from Example 1 is that the fireproof sealing material also includes 1 part of mesoporous silica, and ammonium polyphosphate is loaded in the pores of the mesoporous silica;

[0049] The steps of loading ammonium polyphosphate on mesoporous silica are: add mesoporous silica to deionized water to form a suspension, then add ammonium polyphosphate to the suspension to disperse evenly, and the weight ratio of ammonium polyphosphate to silicon dioxide is 0.1:1, the micropore diameter of mesoporous silica is 40nm, the particle diameter of ammonium polyphosphate is 10nm, and then it is ultrasonically treated for 10min, filtered and dried.

[0050] Among them, step 2 specifically includes adding all the raw materials into the screw mixer in the order of perlite powder, gypsum powder, clay powder and premix, and then adding mesoporous silica loaded with ammonium polyphosphate, stirring and mixing evenly .

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com