Broken yarn detection system

A technology for yarn breakage detection and detection mechanism, applied in textiles and papermaking, etc., can solve the problems of non-compliance with production requirements, low efficiency, yarn breakage, etc., and achieve the effect of improving the jitter amplitude, maintaining stability, and increasing stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

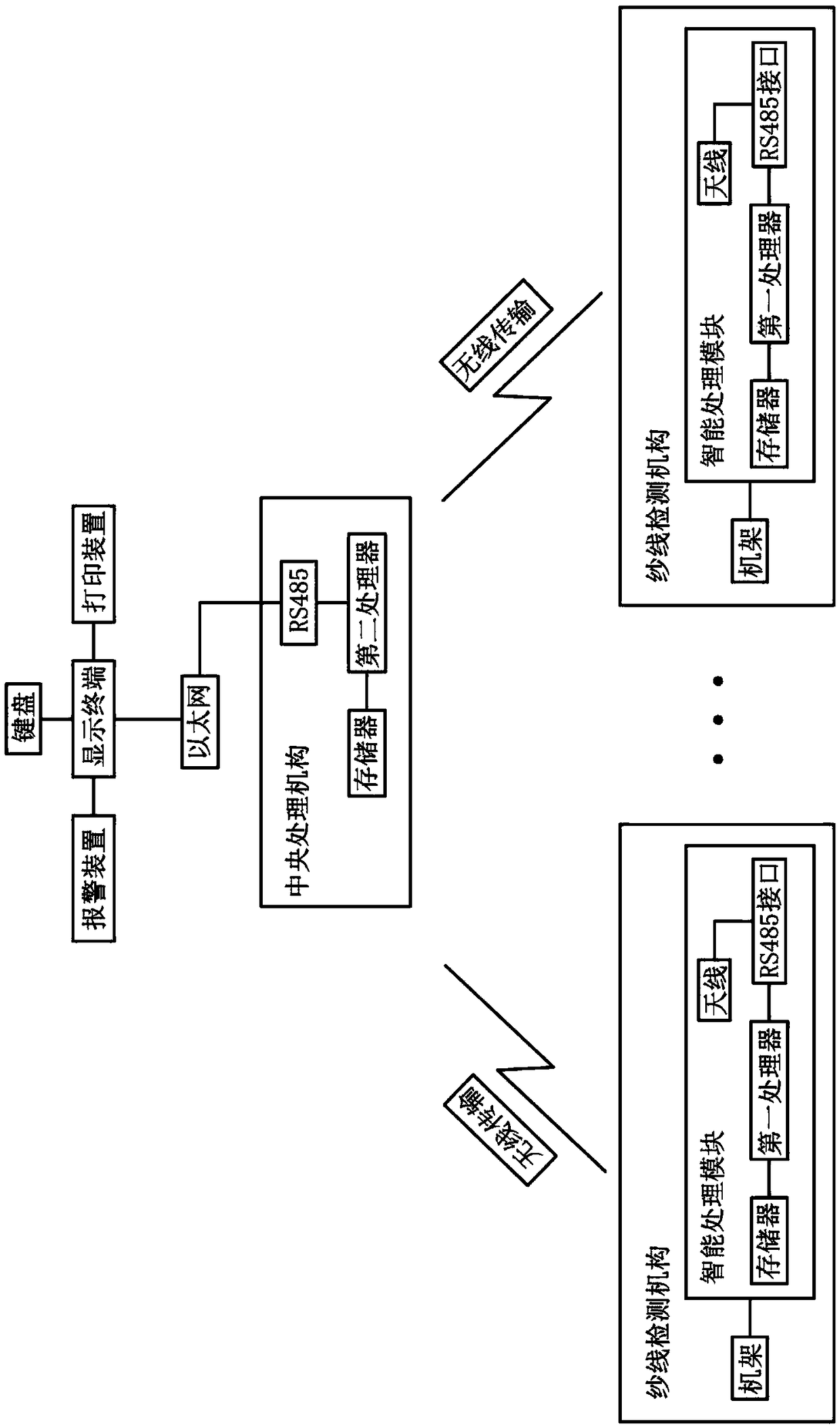

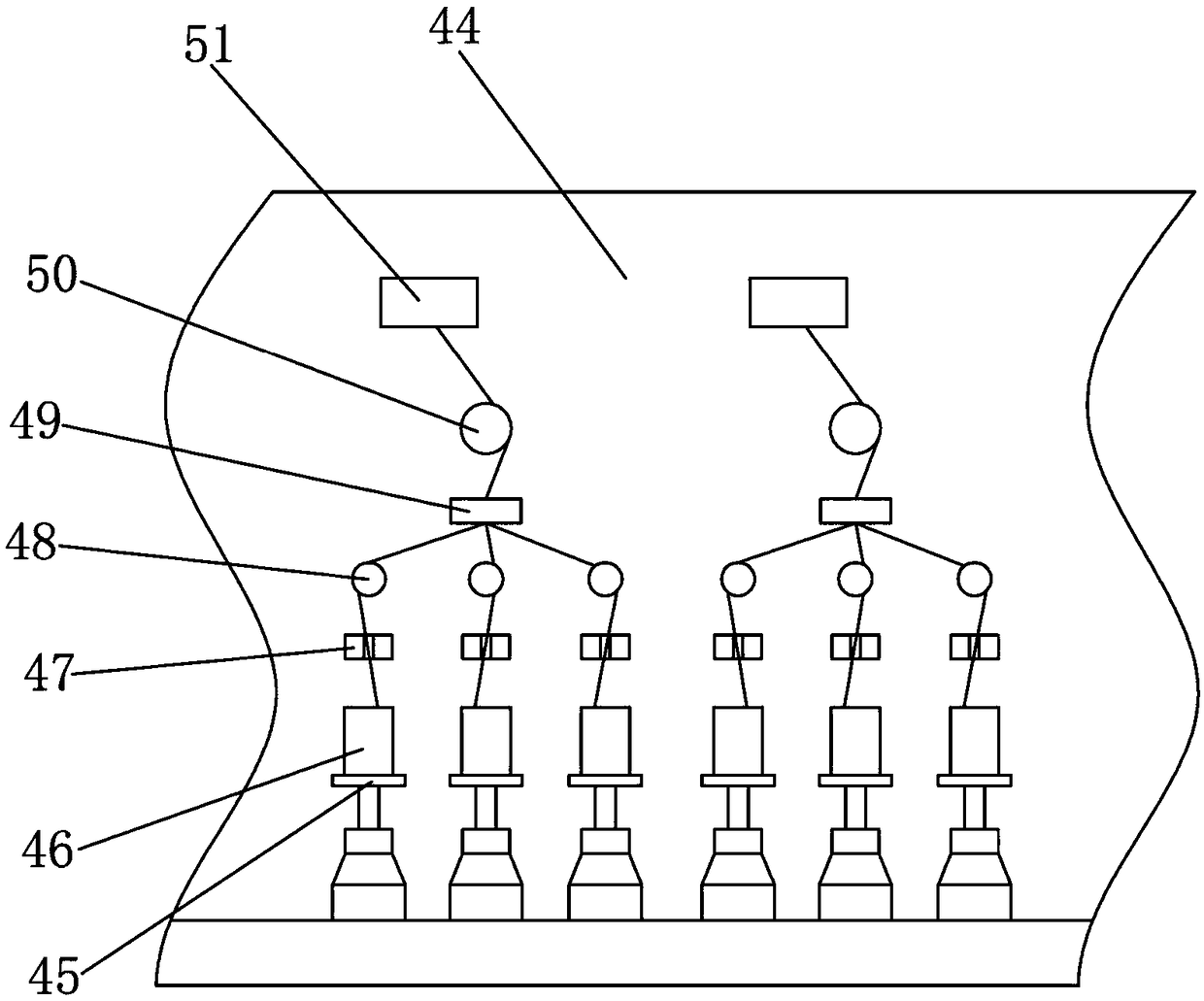

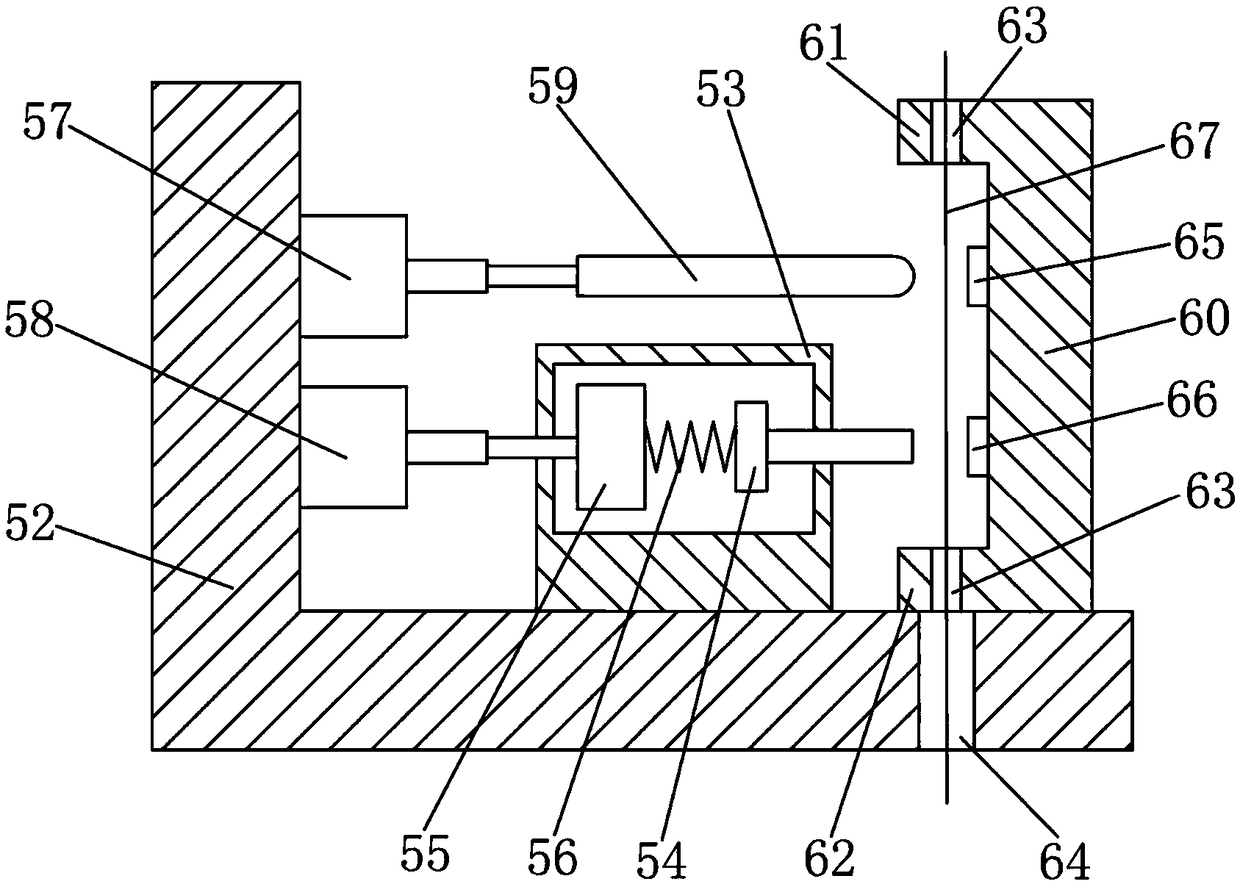

[0029] Embodiment: a kind of broken yarn detection system, such as Figure 1-Figure 12 As shown, it includes several yarn detection mechanisms, a central processing mechanism and a display terminal. The yarn detection mechanism includes a frame and an intelligent processing module arranged on the frame. The bottom of the frame is provided with several twisting discs. Every three adjacent twisting discs are arranged as a group, and a yarn bobbin is arranged on the twisting disc, a thread detector assembly is arranged above the yarn bobbin, and a first guide is arranged above the yarn detector assembly. Yarn rolls, each group of twisting discs are provided with winding rollers, second yarn guide rollers and cutting devices in turn from top to bottom, and the cutting device is located above the first yarn guide rollers, the yarn detector assembly, the second yarn guide A guide roller, a second guide roller, a cutting device and a winding roller are all fixedly installed on the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com