Application method of rigid drilling tool for coiled tubing sidetracking horizontal well

A technology of sidetracking horizontal wells and application methods, which is applied in the direction of drilling equipment and methods, directional drilling, drilling equipment, etc., and can solve problems such as elastic-plastic deformation, small actual footage, and small inner hole area of coiled tubing, etc., to increase the length , extend the length, overcome the effect of short drilling section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] In order to overcome the problem that the existing coiled tubing sidetracking horizontal well rigid drilling tool increases the length of the horizontal section of the sidetracking horizontal well, resulting in a gradual decrease in the effective drilling pressure at the bottom of the well, this embodiment provides a coiled tubing sidetracking The application method of the rigid drilling tool of horizontal well comprises the following steps:

[0028] Step 1: Connect the rigid drill string to the lower end of the coiled tubing 9, the length of the rigid drill string is 600-700m, and then lower the coiled tubing 9 and the rigid drill string to a designated position in the horizontal well through a coiled tubing machine;

[0029] Step 2, under the action of 2-3.5 tons of drilling weight, drill the rigid drill string into 10-20m;

[0030] Step 3: During the drilling process, observe the amount of cuttings returning from the wellhead. If the amount of cuttings returning from...

Embodiment 2

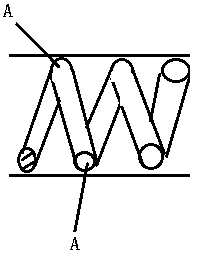

[0035] On the basis of Example 1, in step 4, when the coiled tubing 9 has undergone severe helical bending (such as figure 2 and image 3 shown), repeatedly lift and move the rigid drill string, each time lift the movable rigid drill string 10-15m.

[0036] By lifting the movable rigid drill string, the degree of bending of the spiral tube of the coiled tubing 9 is reduced, and the flow area of the deformed part of the coiled tubing 9 is restored, so that the pressure and displacement of the circulating pump are restored.

Embodiment 3

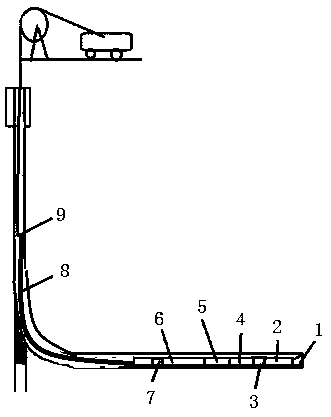

[0038] On the basis of Example 1, such as figure 1 As shown, the rigid drill string consists of drill bit 1, MWD downhole inclinometer 2, screw rod 3, drill pipe one 4, hydraulic oscillator one 5, weighted drill pipe 6, hydraulic oscillator two 7, drill pipe from bottom to top Two 8 are connected in turn to form. The rigid drill string design given in this example can effectively prolong the length of the sidetracking horizontal section of the coiled tubing gas well and reduce the helical bending degree of the coiled tubing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com