Lateral inlet pump station model test rectification method

A model test and pumping station technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as deterioration of pump water absorption conditions, vibration of pump room and unit, and decrease in efficiency of water pump devices, so as to improve reliability and economy, reduce sediment deposition, and improve operational performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention but not to limit the scope of the present invention.

[0031] The model test rectification method of the lateral inflow pumping station includes the following steps:

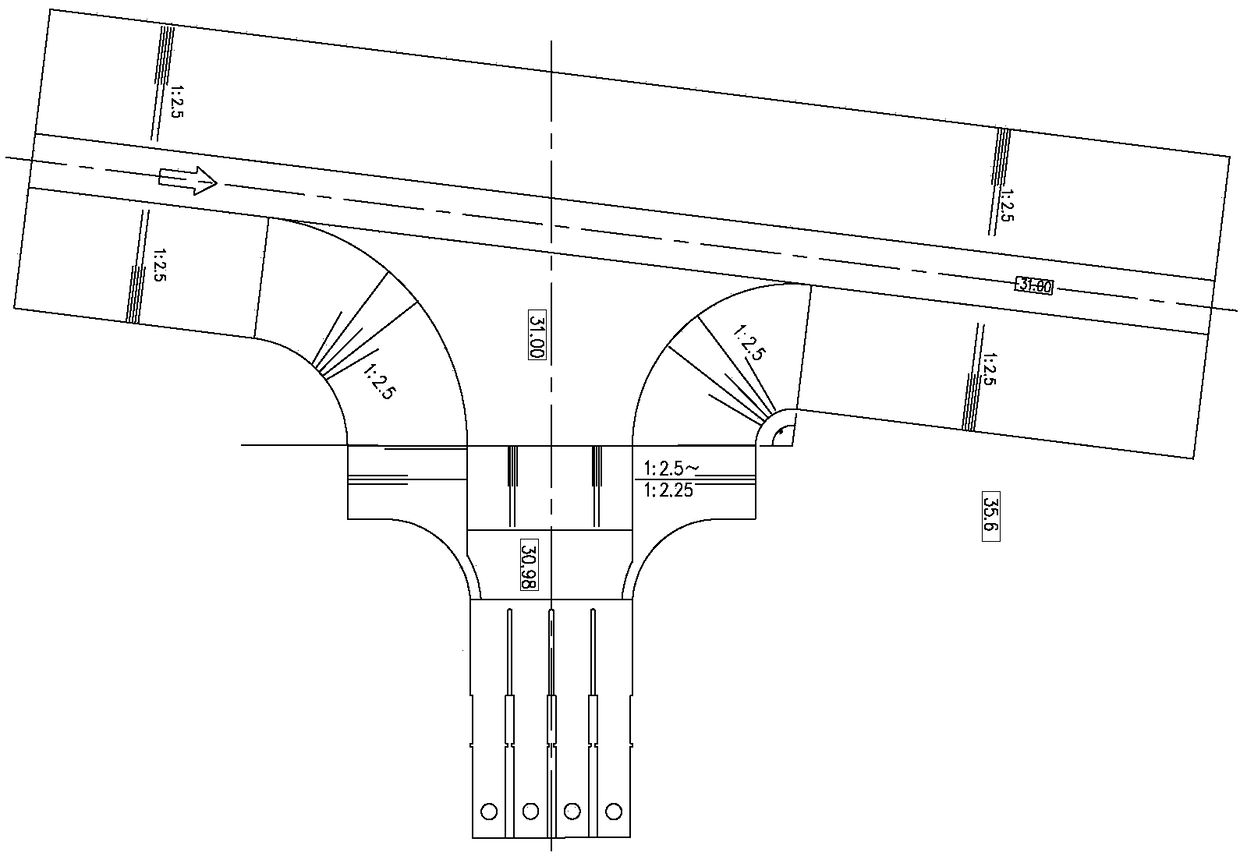

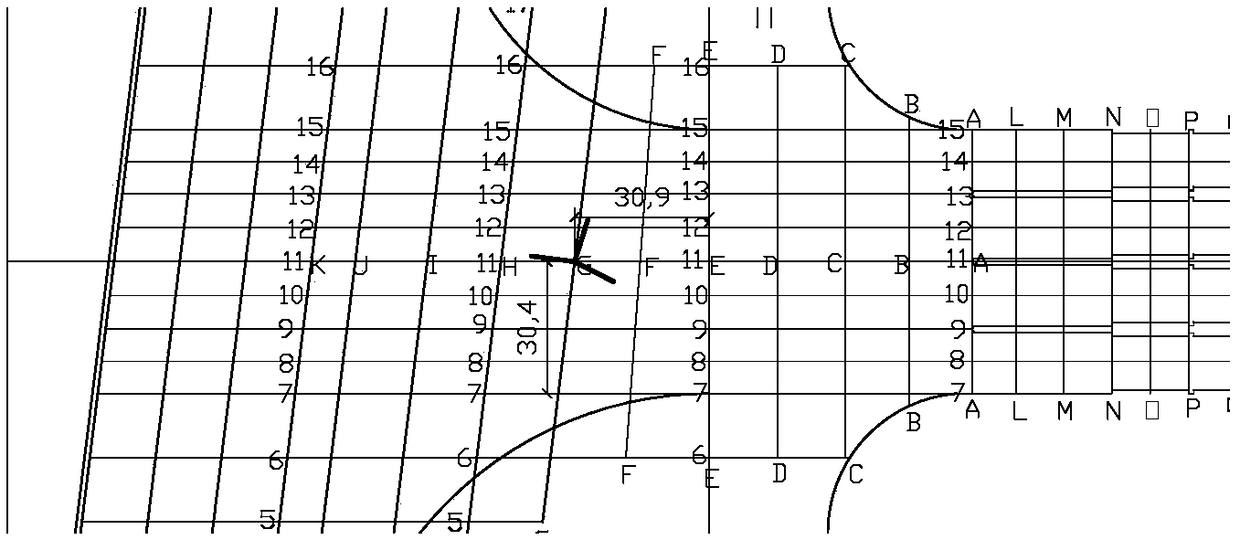

[0032] Step 1: Set up the rectification scheme for the forebay of the lateral inflow pumping station.

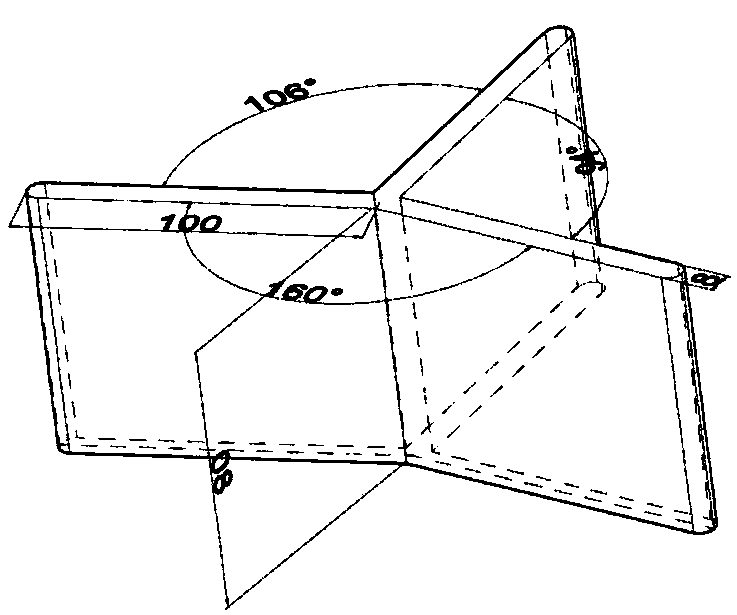

[0033] "T"-shaped diversion pier, the top elevation of "T"-shaped diversion pier is equal to the lowest water level. The side length is 10cm (2.5m). The angles of each side of the diversion pier are rounded.

[0034] Step 2: Build a physical model according to the setup scheme.

[0035] The scope of the forebay flow model includes the diversion river, the forebay, the water inlet pond and the water inlet pipe (including the trumpet pipe). The upstream boundary of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com