Electrode material for lithium-ion secondary battery and lithium-ion secondary battery

A technology for electrode materials and secondary batteries, which is applied in the field of electrode materials for lithium-ion secondary batteries and lithium-ion secondary batteries, can solve problems such as poor input and output characteristics, Li ion diffusivity, and low electronic conductivity, and achieve charging Effect of improving discharge characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

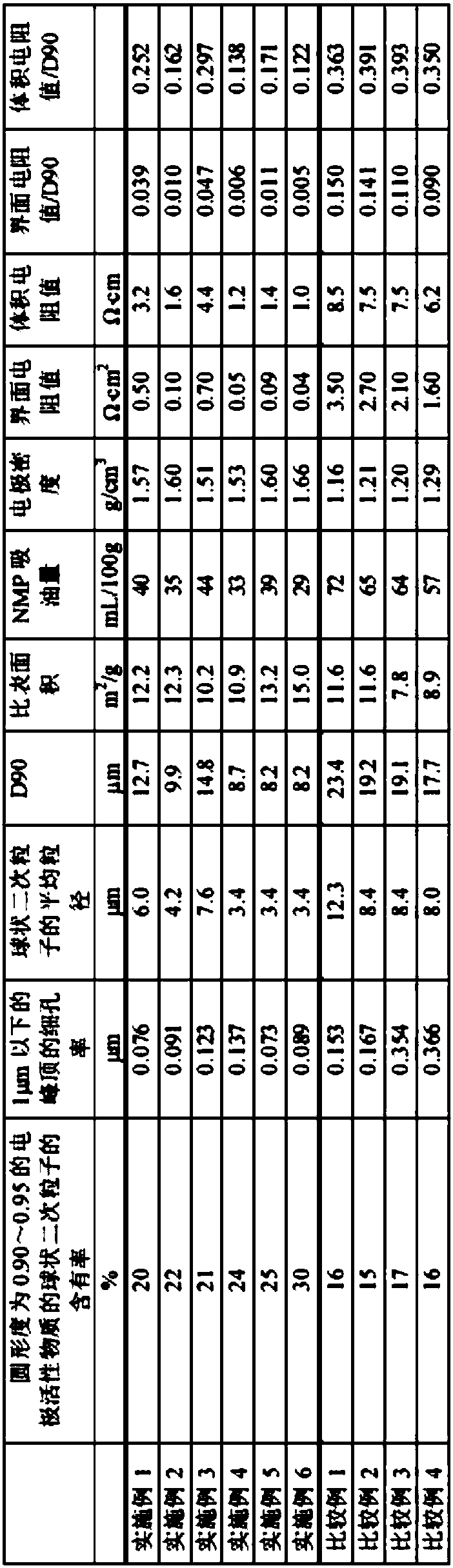

Examples

Embodiment 1

[0133] Lithium phosphate (Li 3 PO 4 ) and iron(II) sulfate (FeSO 4 ) are mixed in a molar ratio of Li:Fe:P=3:1:1. Furthermore, distilled water for preparation was mixed to prepare 600 ml of raw material slurry.

[0134] Next, the raw material slurry was stored in a pressure-resistant airtight container, hydrothermally synthesized at 180° C. for 2 hours, and then cooled to room temperature (25° C.) to obtain cake-shaped electrode active material particles precipitated in the container. After sufficiently washing the electrode active material particles with distilled water several times, the electrode active material particles and distilled water were mixed so that the concentration of the electrode active material particles became 60% by mass to prepare a suspension slurry.

[0135] This suspension slurry is dropped into sand mixer together with the zirconia ball of diameter 0.1mm, with the particle diameter (D90) of cumulative volume percentage 90% in the accumulation parti...

Embodiment 2

[0139] To the slurry that has been subjected to dispersion treatment by a sand mixer, a citric acid aqueous solution adjusted to 30% by mass in advance of 1.0% by mass in terms of citric acid solids is mixed with respect to the electrode active material particles, and the electrode in the slurry is further mixed. Except having mixed distilled water so that the active material particle concentration might become 25 mass %, it carried out similarly to Example 1, and produced the positive electrode material for lithium ion secondary batteries of Example 2.

Embodiment 3

[0141] The suspension slurry that is adjusted to be 60 mass % with the zirconia ball of diameter 1mm is dropped into the sand mixer together with the zirconia ball that is adjusted to the electrode active material particle concentration, in the electrode active material particle in the suspension slurry, with ratio (D90 / D10 ) was 25, except that the treatment time of the ball mill was adjusted and dispersion treatment was performed, and the positive electrode material for lithium ion secondary batteries of Example 3 was produced in the same manner as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com