Electrostatic generation device and electrostatic dust remover

An electrostatic precipitator and electrostatic generation technology, applied in the direction of external electrostatic separator, electrostatic separation, electrode structure, etc., can solve the problems of low dust removal efficiency, easy breakage and damage of conductive threads, etc., to improve adsorption efficiency, solve easy breakage, improve The effect of durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with specific embodiments.

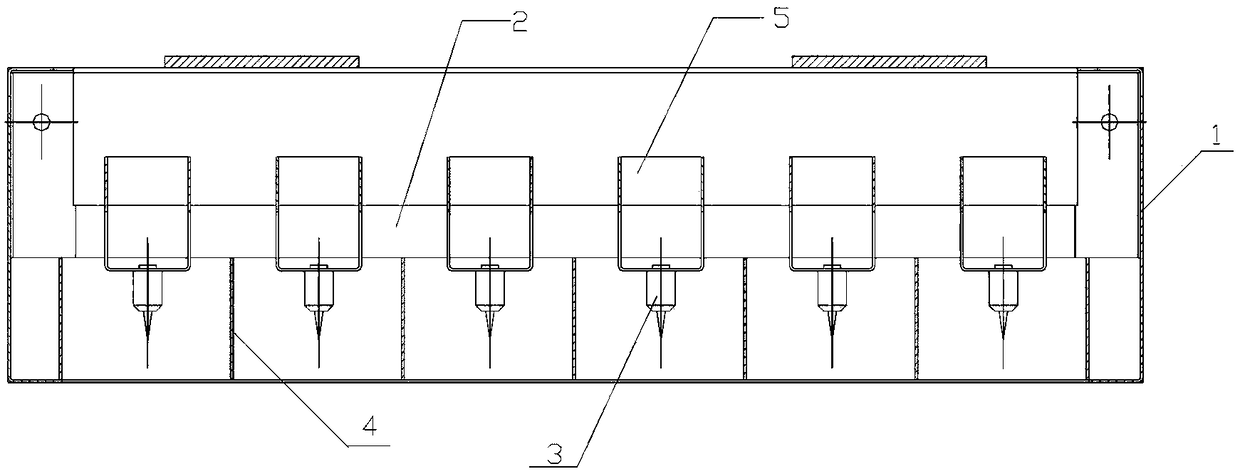

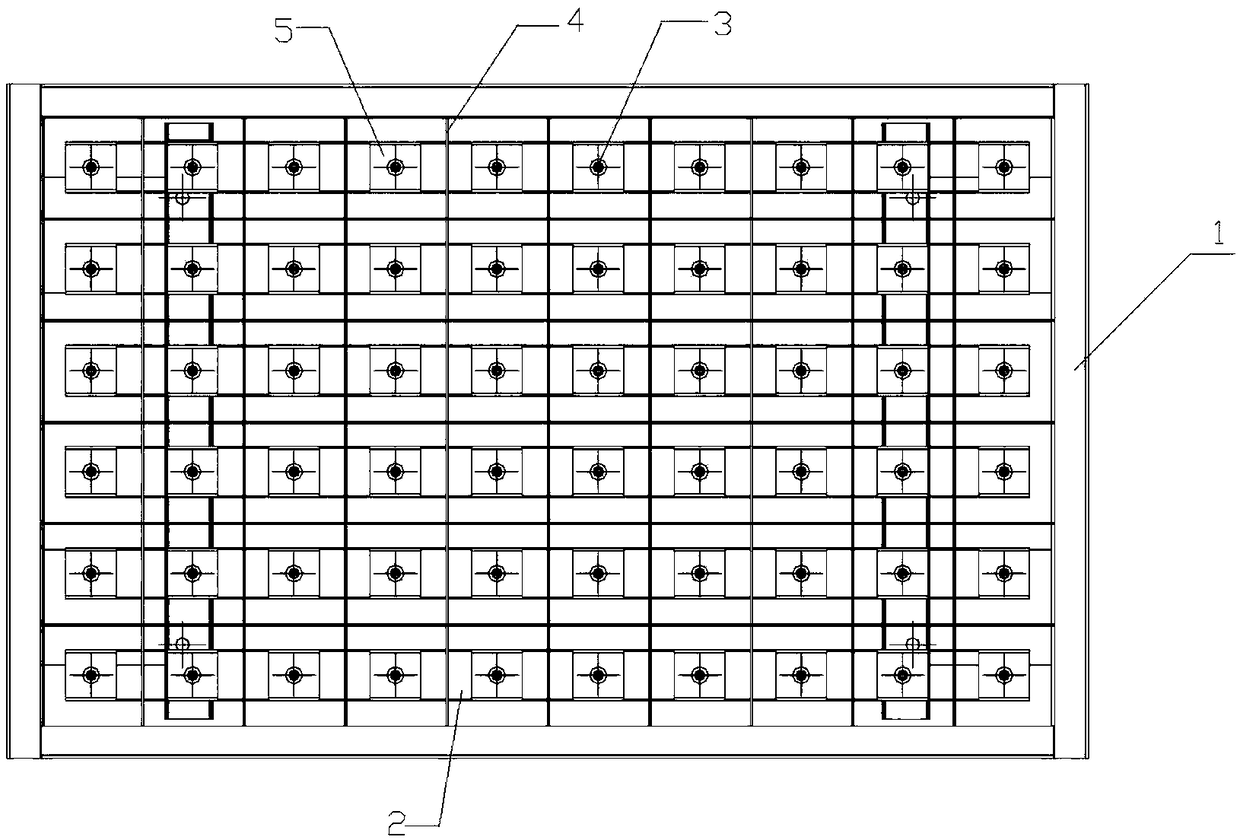

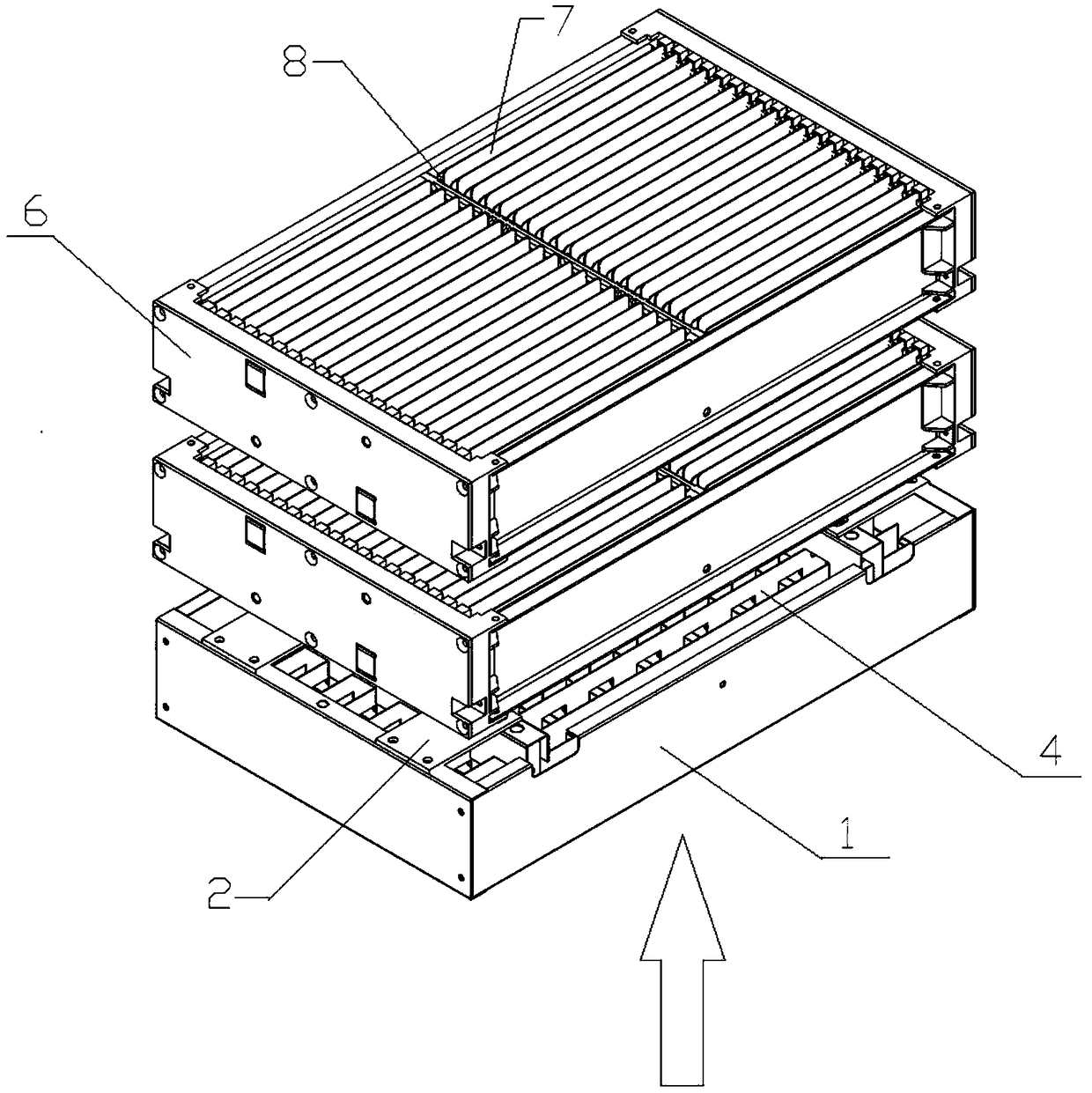

[0021] Such as figure 1 , figure 2 As shown, the present invention provides a kind of static electricity generation device, comprises frame 1, and described frame 1 is provided with some parallel beams 2, and beam 2 is provided with some installation holes; The needle 3 includes a needle body and a needle point. The positive needles 3 are installed in the installation holes with the needle points facing down; negative plates 4 are arranged around the needle points of the several positive needles 3, so that each positive needle 3 is located in an independent space. The positive pin 3 is connected to the positive pole of the power supply, and the negative plate 4 is connected to the negative pole of the power supply. The positive needle 3 generates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com