A multifunctional laser engraving device

A laser engraving and multi-functional technology, applied in laser welding equipment, metal processing equipment, welding equipment, etc., can solve the problem of single function and achieve the effect of convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

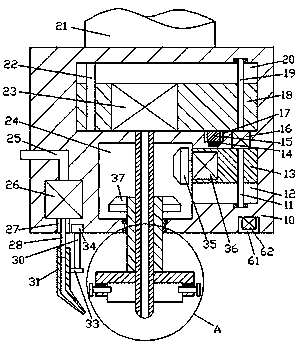

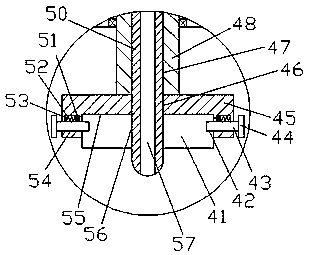

[0014] Combine below Figure 1-2 The present invention will be described in detail.

[0015] refer to Figure 1-2 , a multifunctional laser engraving device according to an embodiment of the present invention, comprising a processing body 10 fixedly installed on the lower side of the adjusting arm 21, the inner wall of the processing body 10 is provided with a transmission cavity 24, and the transmission cavity 24 The processing body 10 at the top is provided with an adjustment cavity 20, and an adjustment frame 18 is installed in the adjustment cavity 20 for sliding fit, and the inner wall on the right side of the transmission cavity 24 is communicated with a sliding cavity 12, and a sliding cavity 12 is installed in the sliding cavity 12. A sliding seat 13 is cooperatingly installed, and a first motor 16 is fixed between the sliding chamber 12 and the regulating chamber 20, and an upper threaded rod 19 is connected to the top end of the first motor 16 with power cooperation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com