Slide type hand-operated safety chuck convenient for placing, clamping and taking out extended and retracted roll materials

A safety chuck and sliding technology, applied in the field of sliding hand-operated safety chucks, can solve the problems of increased roll swing, decreased product quality, inconvenience in subsequent production, etc., and achieves small circular runout and high use accuracy. , The effect of strong anti-deformation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

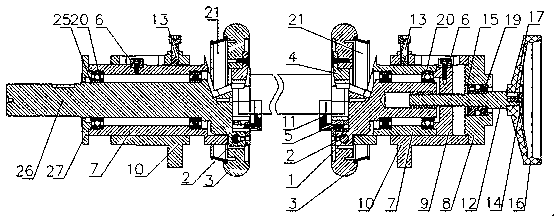

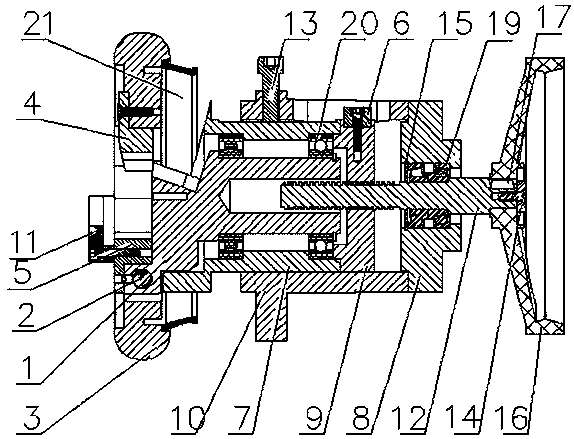

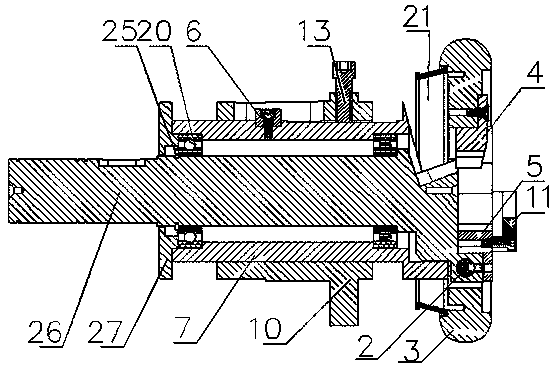

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

[0023] Such as Figure 1-4 As shown in , a sliding hand-operated safety chuck that is convenient for rewinding and unwinding the roll material, placing the card, releasing it, and taking it out includes a safety chuck at the support end and a safety chuck at the power end, and the short axis 1 groove of the safety chuck at the support end The block and the long axis 26 grooves of the safety chuck at the power end are fitted with the shaft end of the reel mandrel through an insert; Ring 21, the other end of the disc 3 is clamped to the groove block of the short shaft 1 through an insert, the shaft of the short shaft 1 runs through the disc 3 and the rubber ring 21, and the shaft of the short shaft 1 passes through a symmetrically fitted bearing 20 Connect the inner hole of the sliding sleeve 7, one end of the sliding sleeve 7 is connected to the end cover 9, and is set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com