Preparation method of quick self-drying cleaning liquid for oil lens

A cleaning solution and rapid technology, which can be used in the preparation of detergent mixture compositions, lens cleaning compositions, chemical instruments and methods, etc., can solve problems such as affecting the accuracy of oil lenses, damage to lenses, etc., and achieve low cost and reduce adhesion. Strong, clearing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

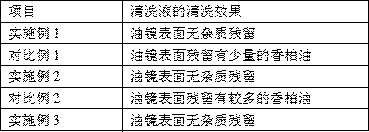

Examples

Embodiment 1

[0015] A preparation method for quick self-drying cleaning fluid for oil mirrors, comprising the following steps:

[0016] (1) Add nano-graphite to methyltrimethoxysilane 4 times its weight, heat the mixture to 88°C, heat it for 6 hours, heat the mixture to 125°C until all the liquid evaporates, and obtain Modified nano-graphite;

[0017] (2) In parts by weight, after mixing 11 parts of methyl p-toluenesulfonate, 3 parts of sodium polydithiodipropane sulfonate, 9 parts of myrcene, 5 parts of modified nano-graphite, and 45 parts of ether, use ultrasonic After 15 minutes of treatment, a quick self-drying cleaning solution for oil immersion lenses was prepared.

[0018] Specifically, in the above step (1), the average particle size of the nano-graphite is 35 nm, and the purity is 99.9%.

[0019] Specifically, in the above step (1), the purity of sodium polydithiodipropane sulfonate is 96%, and the purity of myrcene is 99%.

[0020] Specifically, in the above step (2), the freq...

Embodiment 2

[0022] A preparation method for quick self-drying cleaning fluid for oil mirrors, comprising the following steps:

[0023] (1) Add nano-graphite to methyltrimethoxysilane 5 times its weight, heat the mixture to 90°C, heat it for 7 hours, heat the mixture to 128°C until all the liquid evaporates, and obtain Modified nano-graphite;

[0024] (2) In parts by weight, after mixing 13 parts of methyl p-toluenesulfonate, 5 parts of sodium polydithiodipropane sulfonate, 11 parts of myrcene, 7 parts of modified nano-graphite, and 48 parts of ether, use ultrasonic After 18 minutes of treatment, a quick self-drying cleaning solution for oil mirrors was prepared.

[0025] Specifically, in the above step (1), the average particle size of the nano-graphite is 38nm, and the purity is 99.9%.

[0026] Specifically, in the above step (1), the purity of sodium polydithiodipropane sulfonate is 96%, and the purity of myrcene is 99%.

[0027] Specifically, in the above step (2), the frequency of ...

Embodiment 3

[0029] A preparation method for quick self-drying cleaning fluid for oil mirrors, comprising the following steps:

[0030] (1) Add nano-graphite to methyltrimethoxysilane 6 times its weight, heat the mixture to 94°C, heat it for 8 hours, heat the mixture to 130°C until all the liquid evaporates, and obtain Modified nano-graphite;

[0031] (2) In parts by weight, after mixing 15 parts of methyl p-toluenesulfonate, 6 parts of sodium polydithiodipropane sulfonate, 13 parts of myrcene, 8 parts of modified nano-graphite, and 52 parts of ether, use ultrasonic After 20 minutes of treatment, a quick self-drying cleaning solution for oil mirrors was prepared.

[0032] Specifically, in the above step (1), the average particle size of the nano-graphite is 40 nm, and the purity is 99.9%.

[0033] Specifically, in the above step (1), the purity of sodium polydithiodipropane sulfonate is 96%, and the purity of myrcene is 99%.

[0034] Specifically, in the above step (2), the frequency of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com