Metal gallium cycling electrolysis system

An electrolysis system, gallium metal technology, applied in the field of gallium metal circulation electrolysis system, can solve the problems of low purity, insufficient electrolysis, waste of material resources and manpower, etc., to achieve the effect of increasing the contact area, improving the electrolysis effect, and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

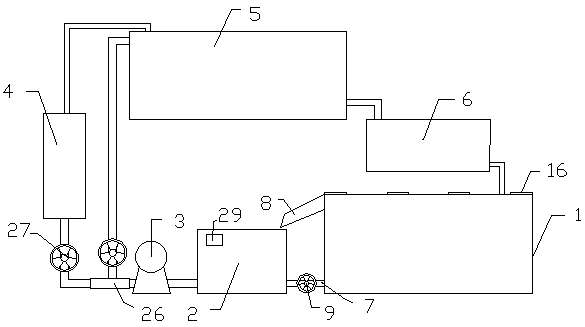

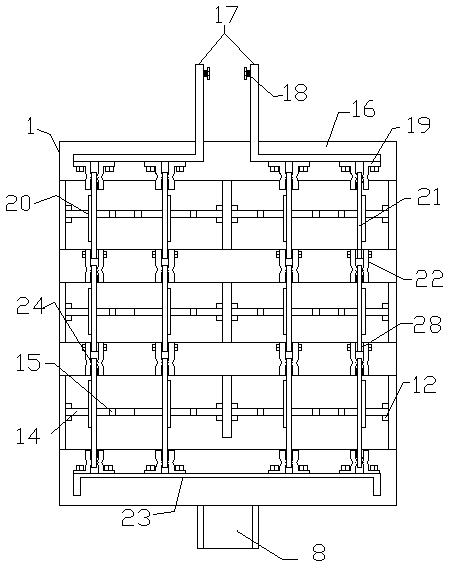

[0036] Such as figure 1Shown: a metal gallium circulation electrolysis system, including electrolytic tank 1, cooling tank 2, small pump 3, cooler 4, high tank 5, buffer tank 6, said electrolytic tank 1, cooling tank 2, high tank 5 , The buffer tank 6 is a rectangular structure, the left end of the electrolytic cell 1 is provided with a discharge port 7 at the lower position, and the left end of the electrolytic cell 1 is provided with an overflow port 8 at the upper position, and the upper position of the discharge port 7 is An on-off valve 9 is provided, the discharge port 7 is connected to the lower right end of the cooling tank 2, a temperature alarm 29 is arranged on the cooling tank 2, and a small pump 3 is connected to the cooling tank 2 through a pipeline. The small pump 3 is connected to the cooler 4 through a pipeline, and the cooler 4 is connected to the left end of the top of the elevated tank 5 through a pipeline, and the lower right end of the elevated tank 5 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com