Corrosion prevention technology of combustion gas-steam combined cycle unit thermal system standby

A combined cycle unit and thermal system technology, applied in gas turbine installations, components of steam boilers, mechanical equipment, etc., can solve problems such as not being used in steam turbines, and achieve the effect of maintaining safety and health, simple operation mode, and good environmental performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

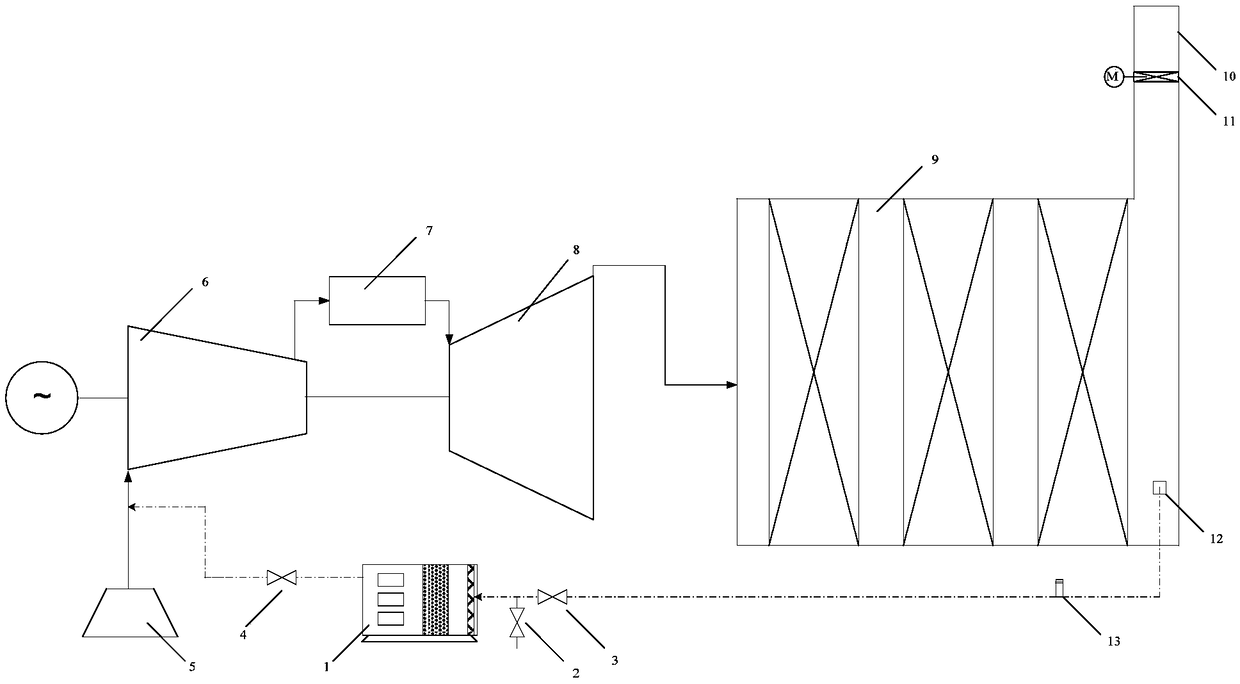

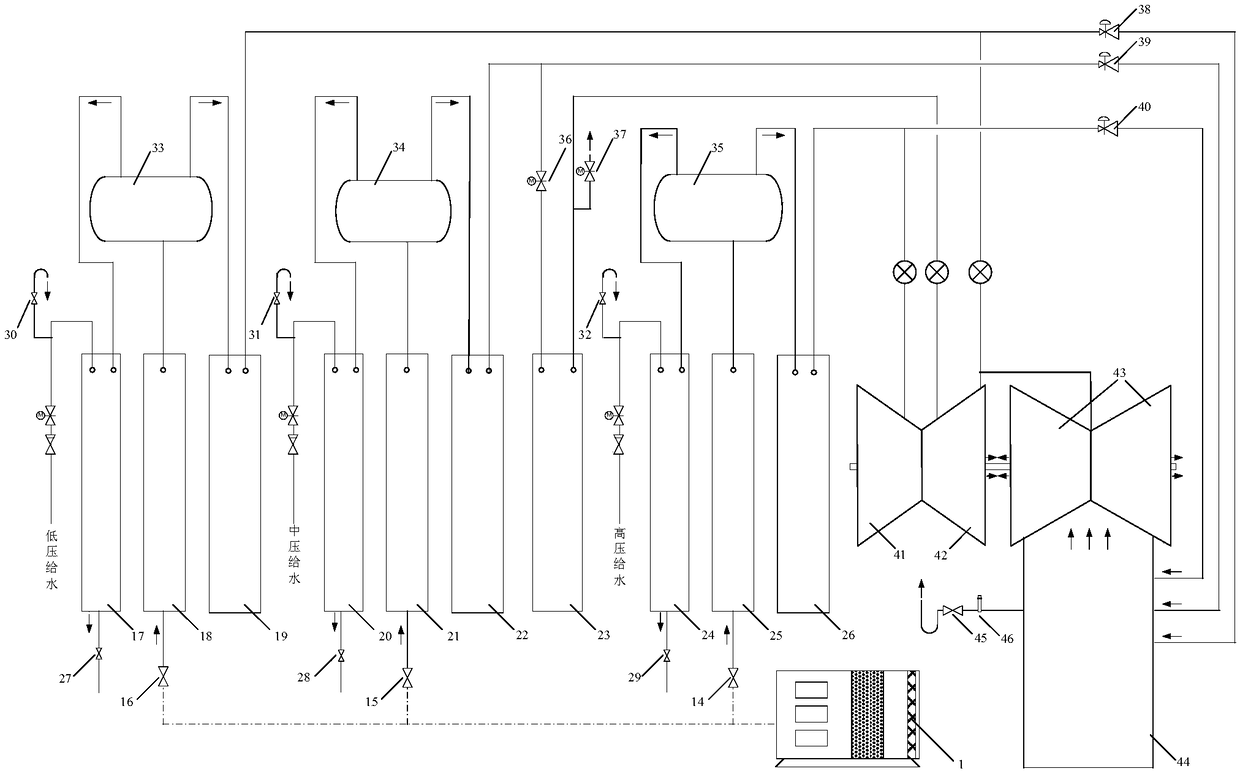

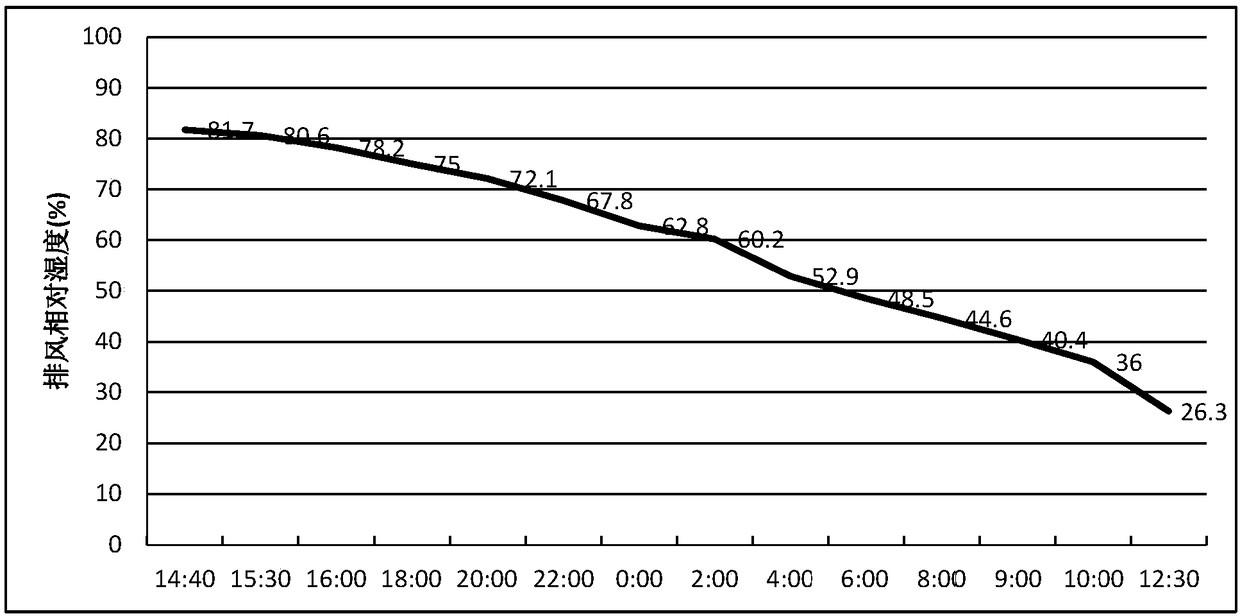

[0037] Dry air combined anti-corrosion process of gas-steam combined cycle unit standby thermal system. This process is based on the theory of corrosion of metals in atmospheric environments. The corrosion of metals in atmospheric environments is the result of the combined action of oxygen, moisture and corrosive media in the air. It is the decisive factor to determine the electrochemical corrosion process. When the relative humidity of the environment is higher than the critical relative humidity of metal atmospheric corrosion, the metal corrosion rate rises sharply. The critical relative humidity of carbon steel material atmospheric corrosion is about 60%, and the corrosion is very slow when it is lower than 50%. , less than 30% basically no corrosion. Dry air combined anti-corrosion process for combined cycle unit shutdown and standby thermal system. This process designs a reasonable shutdown protection system according to the characteristics of the combined cycle unit syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com