Filter device used for benomyl production and used after reactor treatment

A filter device and reactor technology, applied in the direction of filtration separation, mobile filter element filter, separation method, etc., can solve the problems that affect the quality of materials, contain a lot of impurities or foreign objects, etc., achieve fast speed, good effect, and improve service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

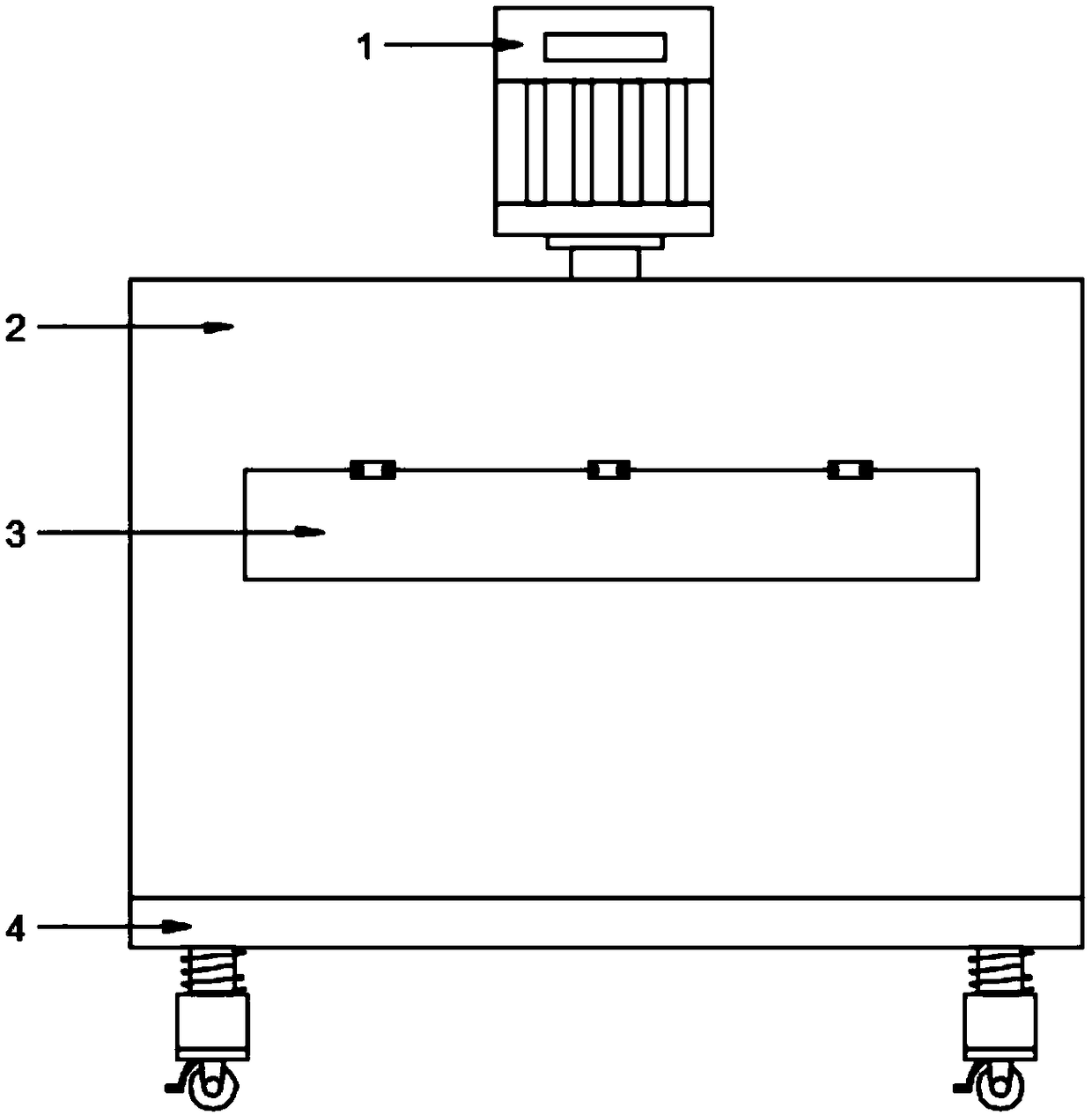

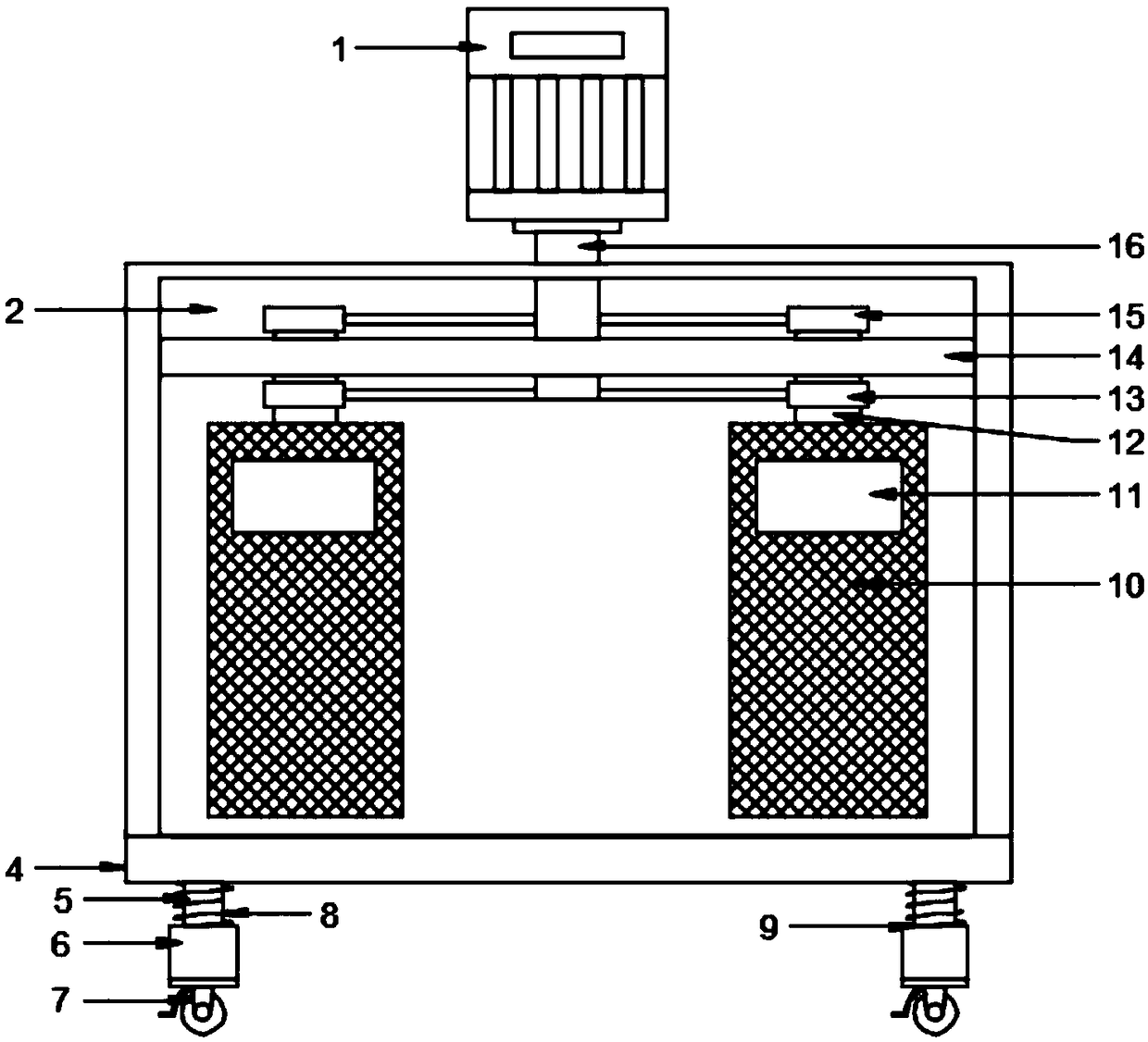

[0024] see figure 1 , 3 And 5, a filter device after the reaction kettle treatment for the production of benomyl, comprising a filter box 2 and a centrifugal drum 10, the lower end of the filter box 2 is fixed with a buffer base 4, and the inside of the filter box 2 is fixed with an internal gear ring 14. The inner toothed ring 14 is set at one-fifth of the inside of the filter box 2 from top to bottom. The second sealing door 11 is installed on the front end of the centrifugal bucket 10, and the transmission shaft 12 is fixed on the upper end of the centrifugal bucket 10. A gear 17 is fixed on the transmission rotating shaft 12, and the gear 17 meshes with the inner gear ring 14.

[0025] A first airtight door 3 is installed on the front end surface of the filter box 2, and a sealing strip is arranged inside the first airtight door 3 .

[0026] The lower end of the buffer base 4 is fixed with four buffer support legs 9 distributed in a rectangular array, the buffer support ...

Embodiment 2

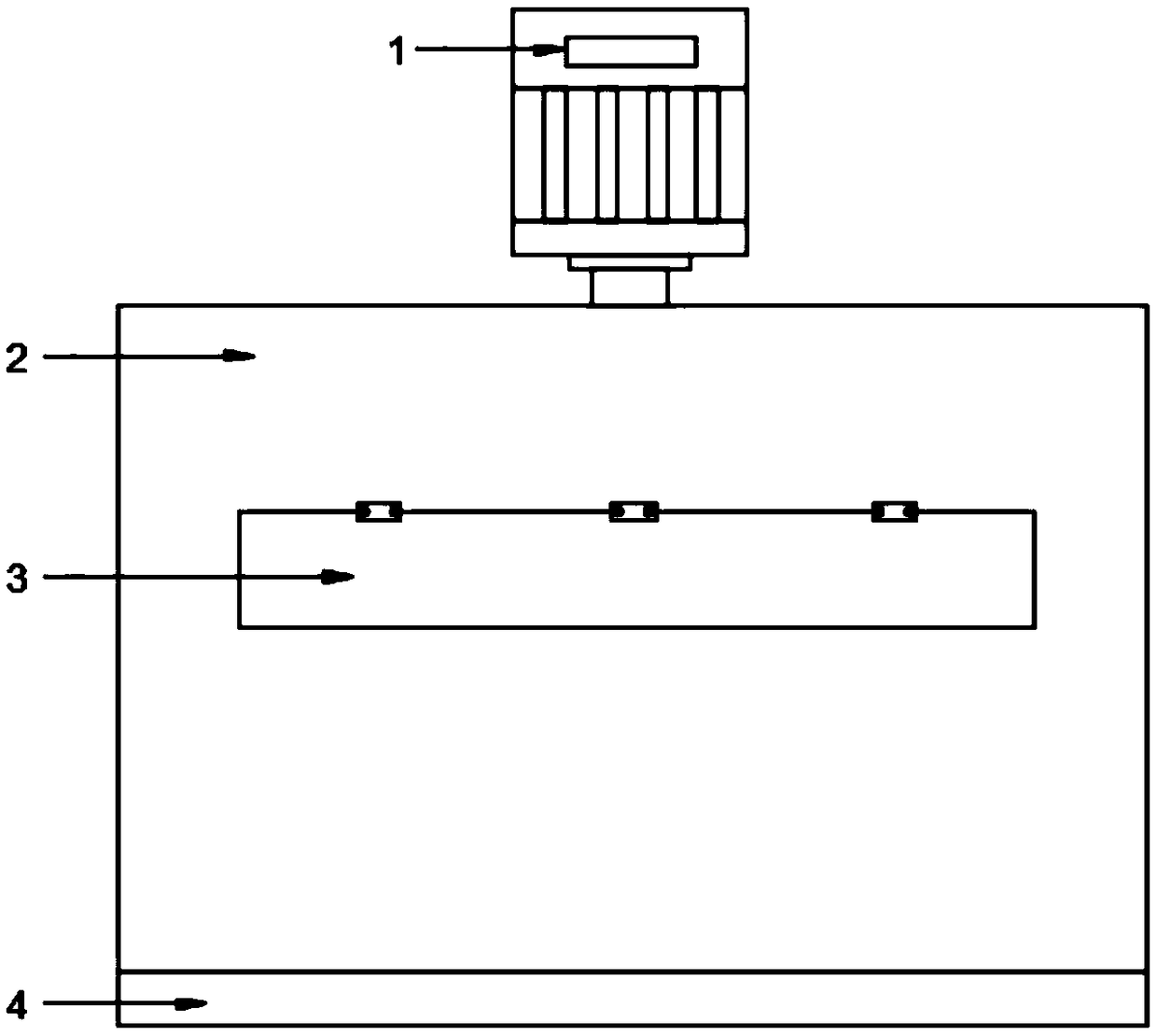

[0029] see figure 2 , 4 And 5, a filter device after the reaction kettle treatment for the production of benomyl, comprising a filter box 2 and a centrifugal drum 10, the lower end of the filter box 2 is fixed with a buffer base 4, and the inside of the filter box 2 is fixed with an internal gear ring 14. The inner toothed ring 14 is set at one-fifth of the inside of the filter box 2 from top to bottom. The second sealing door 11 is installed on the front end of the centrifugal bucket 10, and the transmission shaft 12 is fixed on the upper end of the centrifugal bucket 10. A gear 17 is fixed on the transmission rotating shaft 12, and the gear 17 meshes with the inner gear ring 14.

[0030] A first airtight door 3 is installed on the front end surface of the filter box 2, and a sealing strip is arranged inside the first airtight door 3 .

[0031] The buffer base 4 is provided with an inner support plate 18, the lower end of the inner support plate 18 is interspersed inside t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com