Decorative wood board paint drying device

A technology for decorating wooden boards and drying devices, which is applied to devices for coating liquid on surfaces, pretreatment surfaces, coatings, etc., can solve problems such as low work efficiency, low drying efficiency, complex structure, etc., and achieves promotion of air circulation. , to ensure the drying effect, the effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

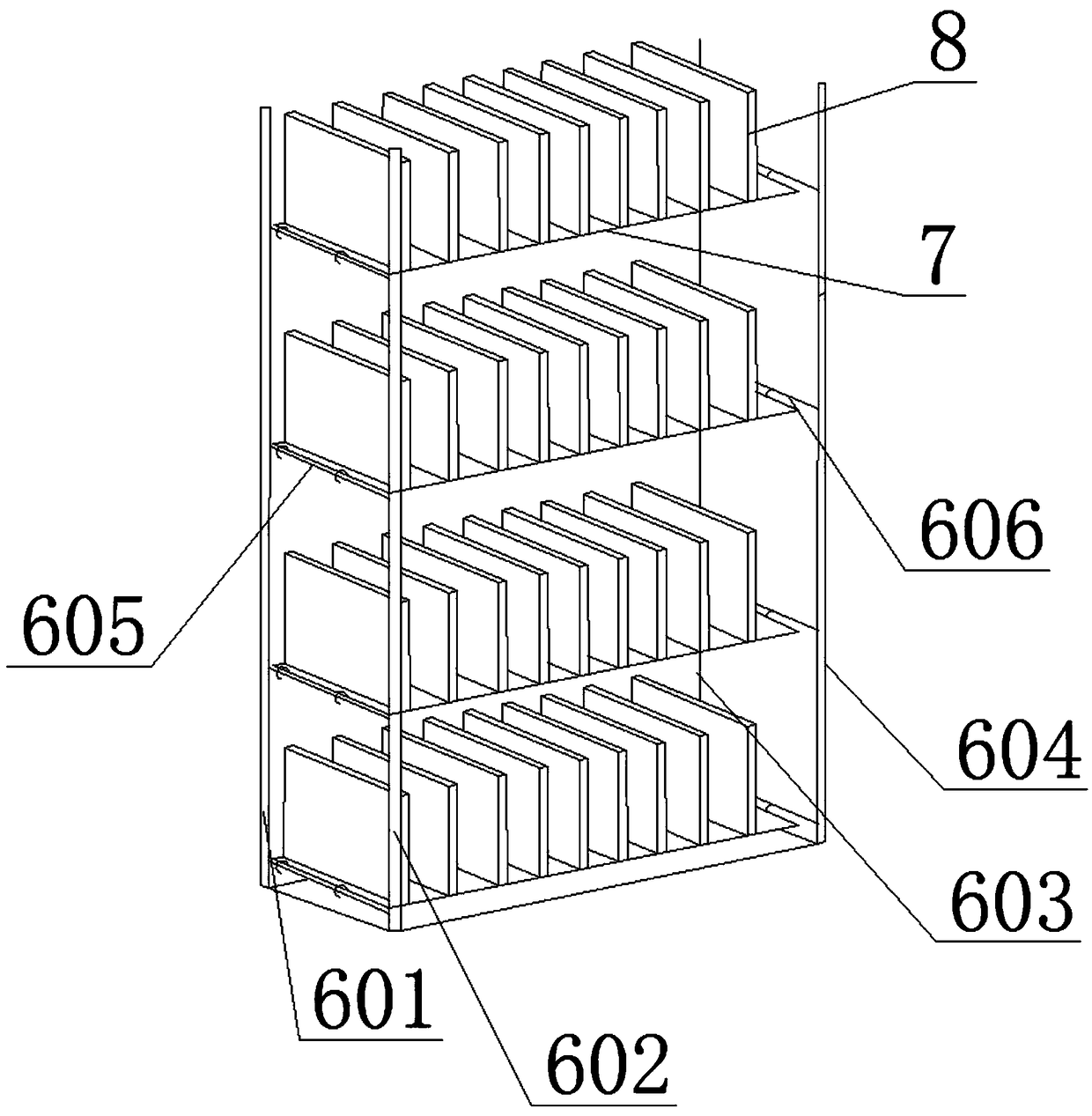

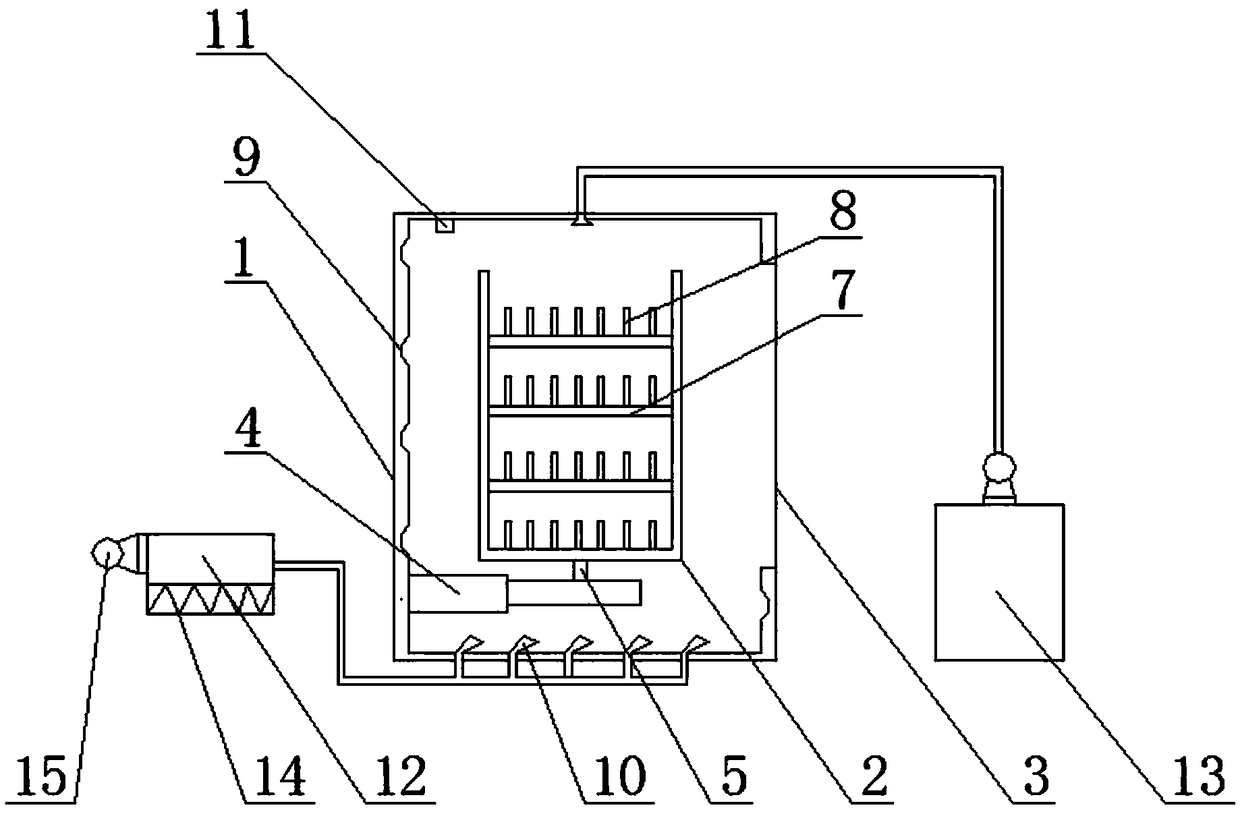

[0026] This embodiment provides a decorative wood paint drying device, which includes a drying box 1 and a placement seat 2. An electric rolling door 3 is provided at the bottom of one side of the drying box 1 for the entry and exit of the placement seat 2. The bottom of the inner wall on one side of the dry box 1 is provided with a hydraulic cylinder 4 for passing the placement seat 2 through the rolling door 3, the placement seat 2 is arranged on the hydraulic cylinder 4, and the placement seat 2 and the hydraulic pressure Between the cylinders 4 is provided a rotating shaft 5 for rotating the placement seat 2 in the vertical direction; Four pillars 604, the first struts 605 that are all arranged between the first pillars 601 and the second pillars 602, the second pillars that are corresponding to the first struts 605 and are all arranged between the third pillars 603 and the fourth pillars 604. Strut 606, the support plate 7 that is movably arranged on the first support 605...

Embodiment 2

[0030] The present embodiment provides a paint drying device on the surface of a wooden board. Compared with Embodiment 1, the difference is that an infrared generator for auxiliary heating is provided in the drying box 1; A dehumidification unit for removing moisture in the hot air flow is provided between the boxes 1, and the dehumidification unit includes two filter screens clamped at the outlet of the heating box 12, and activated carbon filled between the two filter screens; The drying box 1 is provided with a spraying device for cleaning the inside of the drying box 1, and the spraying device includes a spray head arranged on the top of the drying box 1 and an external water source connected to the spray head.

[0031] The infrared generator can assist in heating the wood boards to improve drying efficiency; the dehumidification unit can absorb the water vapor in the hot air flow to prevent the water in the air from affecting the drying effect of the wood boards; 1 The i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com